Gas extraction hole-drilling hole-sealing device and hole-sealing method

A technology of gas extraction and hole sealing device, which is applied in gas discharge, safety device, sealing/sealing and other directions, can solve the problems of easy gas blockage, frequent gas leakage, and short effective time for extraction, and achieves increased bearing stress. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

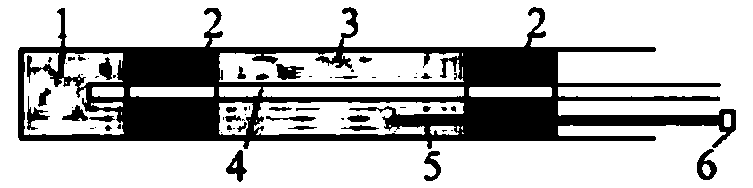

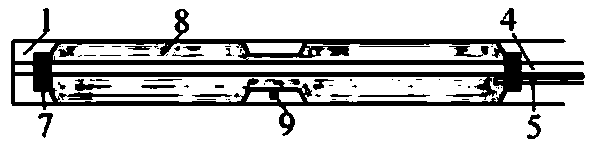

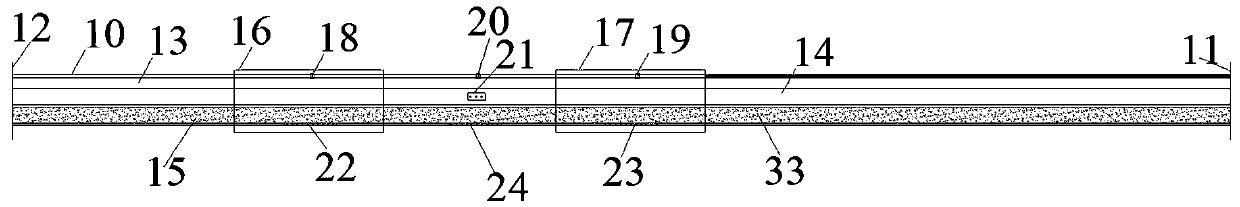

[0036] Such as image 3 and 4 As shown, a gas drainage drilling sealing device includes a solid drainage pipe body 10 for inserting into a gas drainage drilling hole. The material of the drainage pipe body 10 is polycarbonate PC. The drainage pipe body 10 After being inserted into the borehole, the end at the depth of the borehole is called the deep end 11, and the end at the outer edge of the borehole is called the connecting end 12; The extraction channel 14 and the repairing material channel 15, the extraction channel 14 runs through both ends of the extraction pipe body 10 and both ends of the extraction channel 14 are open, the grouting channel 13 and the repairing material channel 15 are at the connection end 12 of the extraction pipe body 10 Both openings, the other ends of the grouting channel 13 and the restoration material channel 15 are closed, and the extraction pipe body 10 is fixedly sleeved with a sealed and flexible first bladder 16, a second bladder 17, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com