Tunnel invert zone division and process division streamlined construction method

A construction method and streamlined technology, which can be used in tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve the problems of suspended face, loss of safety control, poor structural stability, etc., to reduce construction time, lining safety, and guarantee management. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0021] A streamlined construction method for tunnel inverts divided into sub-sections and procedures, comprising the following steps:

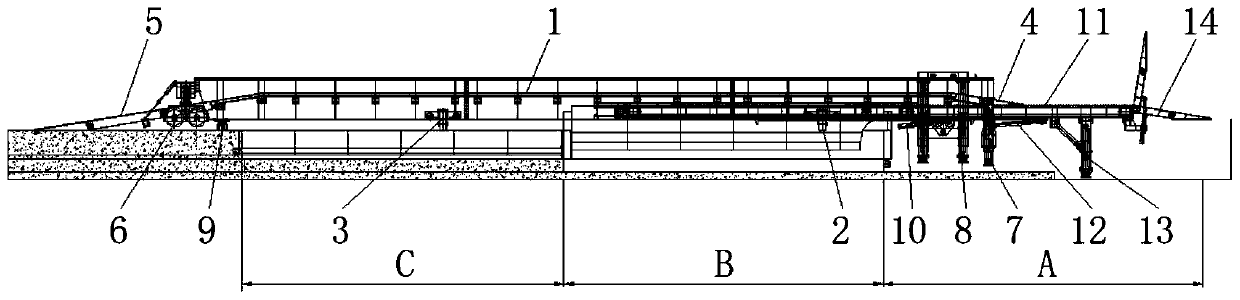

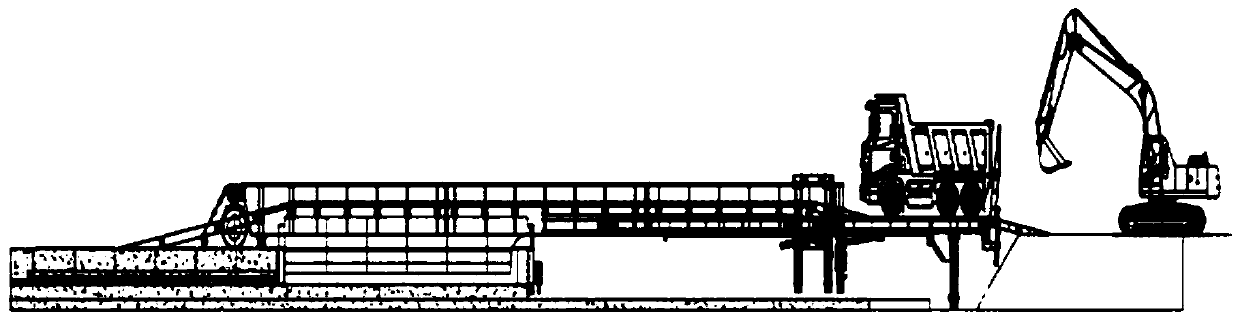

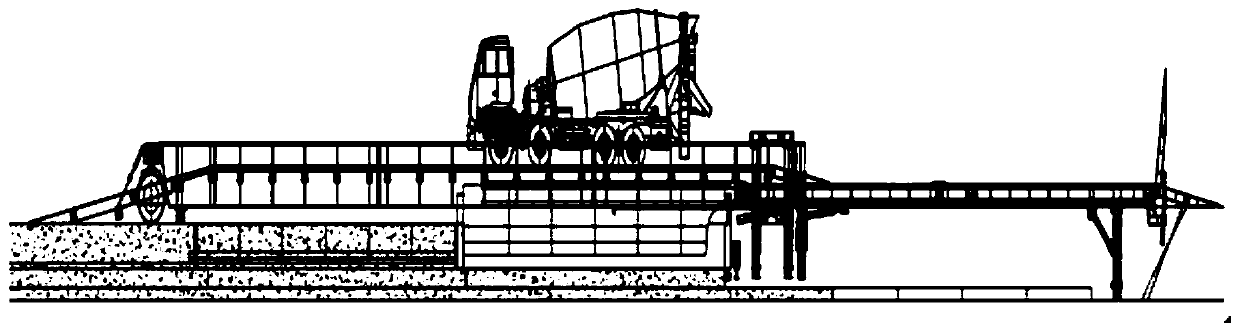

[0022] Step one, such as figure 1 As shown, the telescopic mobile trestle enters the tunnel, and the tunnel invert is divided into three independent operation areas according to the construction of the inverted arch excavation initial support area A, inverted arch lining area B and inverted arch filling area C.

[0023] The telescopic mobile trestle is mainly composed of main bridge 1, front longitudinal moving trolley 2, rear longitudinal moving trolley 3, front approach bridge of main bridge 4, rear approach bridge 5, rear traveling mechanism 6, front outrigger 7, middle outrigger 8, rear outrigger 9. Main bridge longitudinal movement mechanism 10, front guide beam 11, secondary longitudinal movement mechanism 12, auxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Full length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com