Thermal shock test device and method for nanometer-scale wire material

A test device and test method technology, applied in the direction of measurement device, material thermal analysis, material analysis, etc., to avoid friction damage, good protection, and low test cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

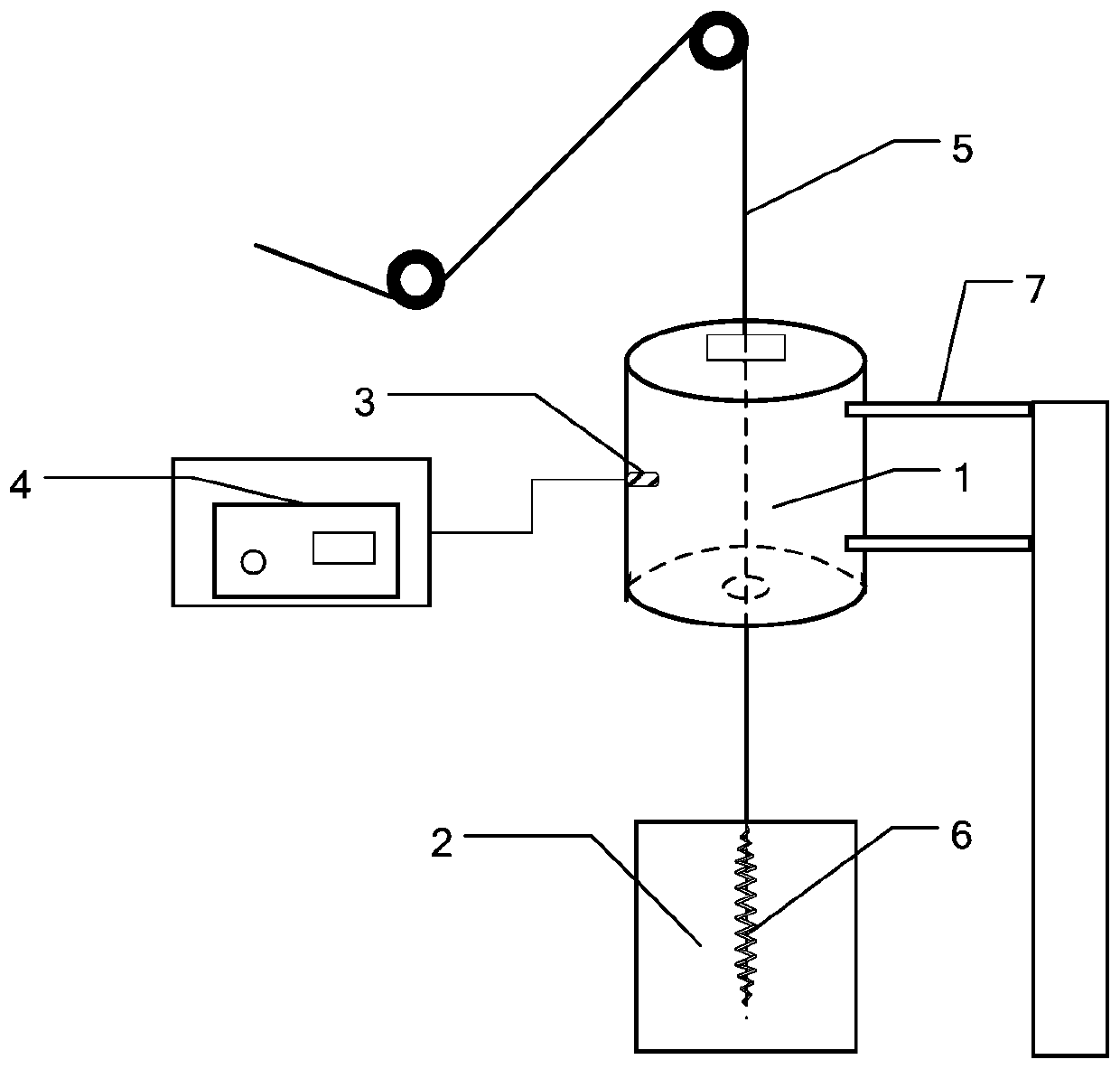

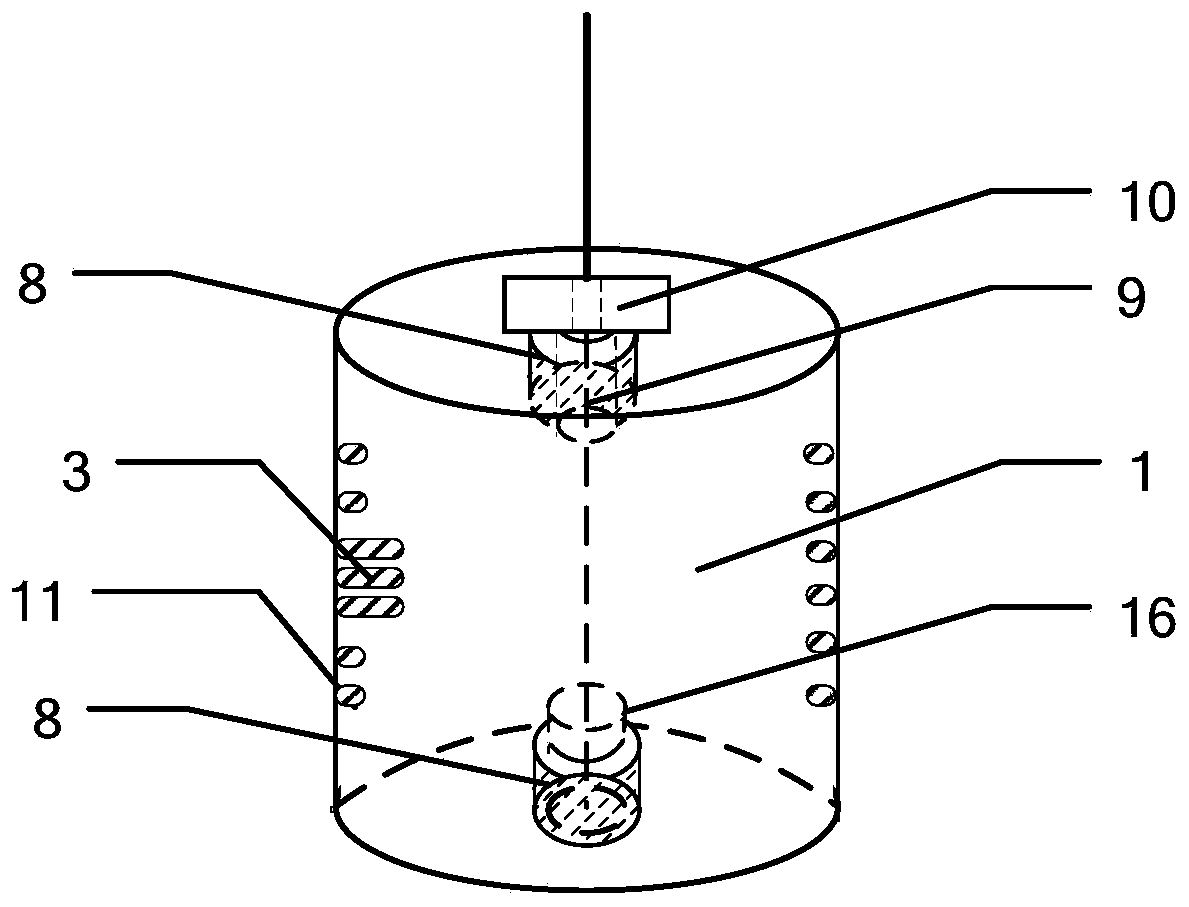

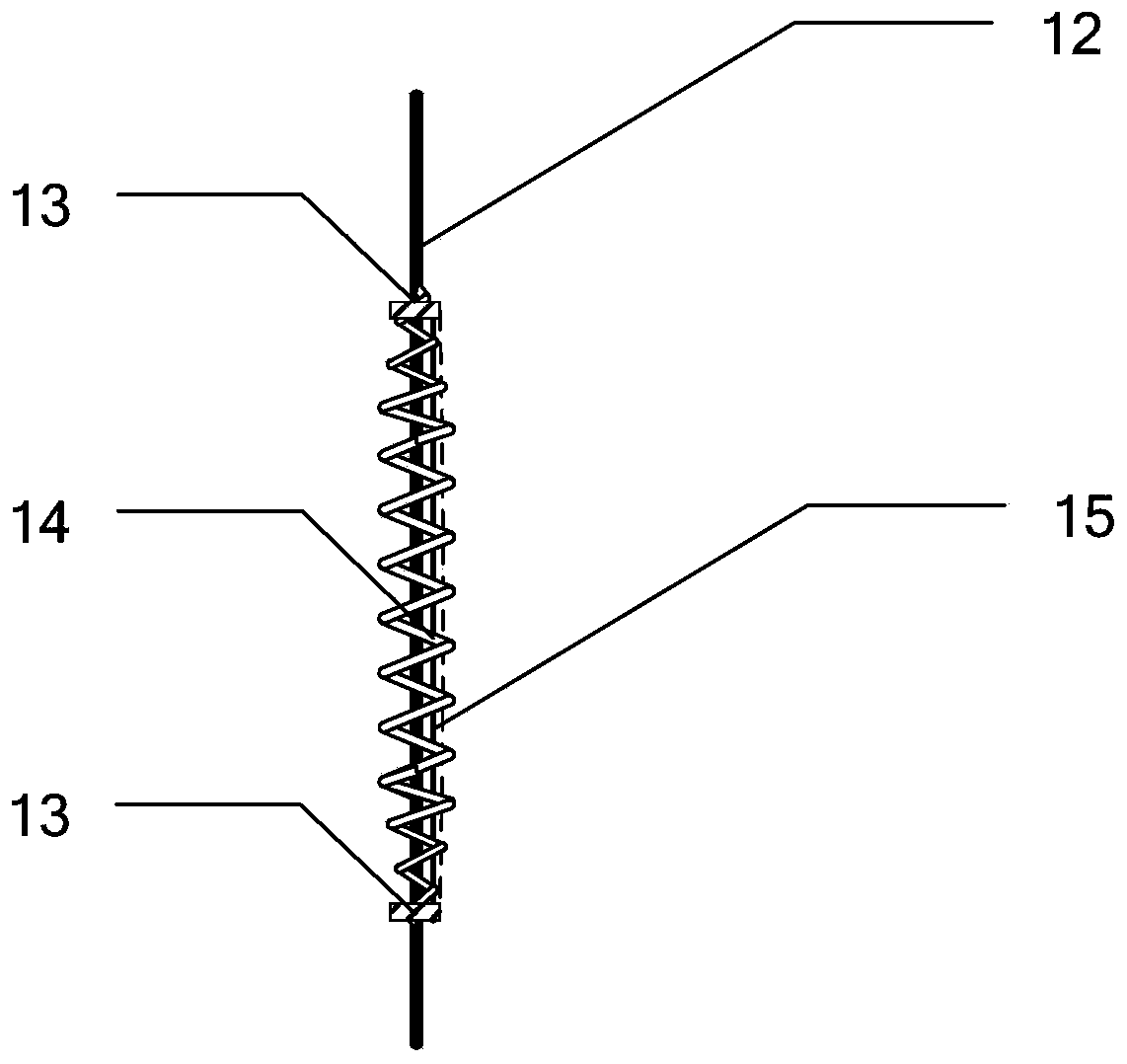

[0035] The thermal shock test device in the patent of the present invention includes a complete set of sample fixing, heating, cooling, temperature control and transfer devices, which is suitable for thermal shock tests of extremely fine wires with diameters of nanometer scale. The thermal shock test device involved in the patent of the present invention has a wide test temperature range, covering the liquid nitrogen temperature (-196°C) and the spacecraft service temperature range of -180°C to 300°C. For the nano-micron scale wire samples, the fixed tooling protected by the helical metal wire sleeve is used for loading, and a certain distance is kept between the wires in a relaxed state to avoid material collision, friction and damage. This method can be used for thermal shock test The materials include, but are not limited to, nanometer-scale filamentary metals, non-metals, composite materials, and coated materials.

[0036] The device of the present invention is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com