Optical proximity effect correction method and correction system

A technology of optical proximity effect and correction conditions, applied in optics, optomechanical equipment, microlithography exposure equipment, etc., can solve the problems of wasting engineers' time, reducing the readability of recipes, increasing the length and complexity of recipes, etc., to reduce risk, increase the pass rate, and improve the effect of product pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0050] The present invention provides a first embodiment of a model-based optical proximity effect correction method, which includes the following steps:

[0051] S1, based on the model, the graphic simulation on the current mask plate is formed into a photoresist profile;

[0052] S2, determining the edge position error according to the relationship between the photoresist profile and the corresponding edge position of the target pattern;

[0053] S3, screening out the opposite sides that meet the preset correction conditions;

[0054] S4, calculate and screen out the pre-movement and actual movement of the opposite side;

[0055] S5, correcting the actual movement amount for the screened opposite sides respectively;

[0056] S6, repeating the above steps S2-S5 until there is no opposite edge satisfying the preset correction condition in the layout.

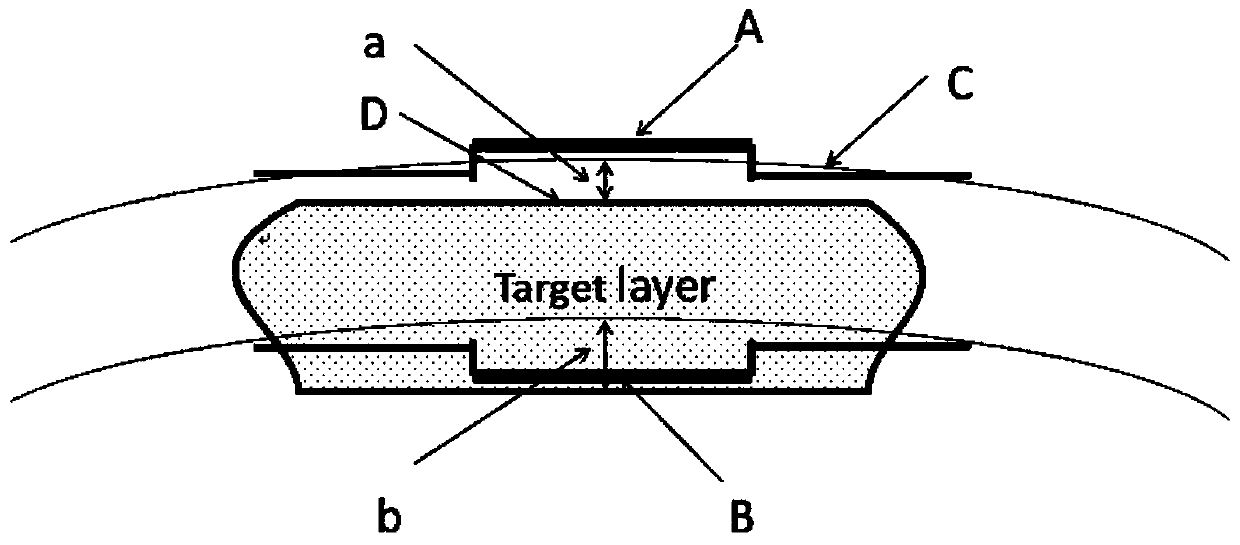

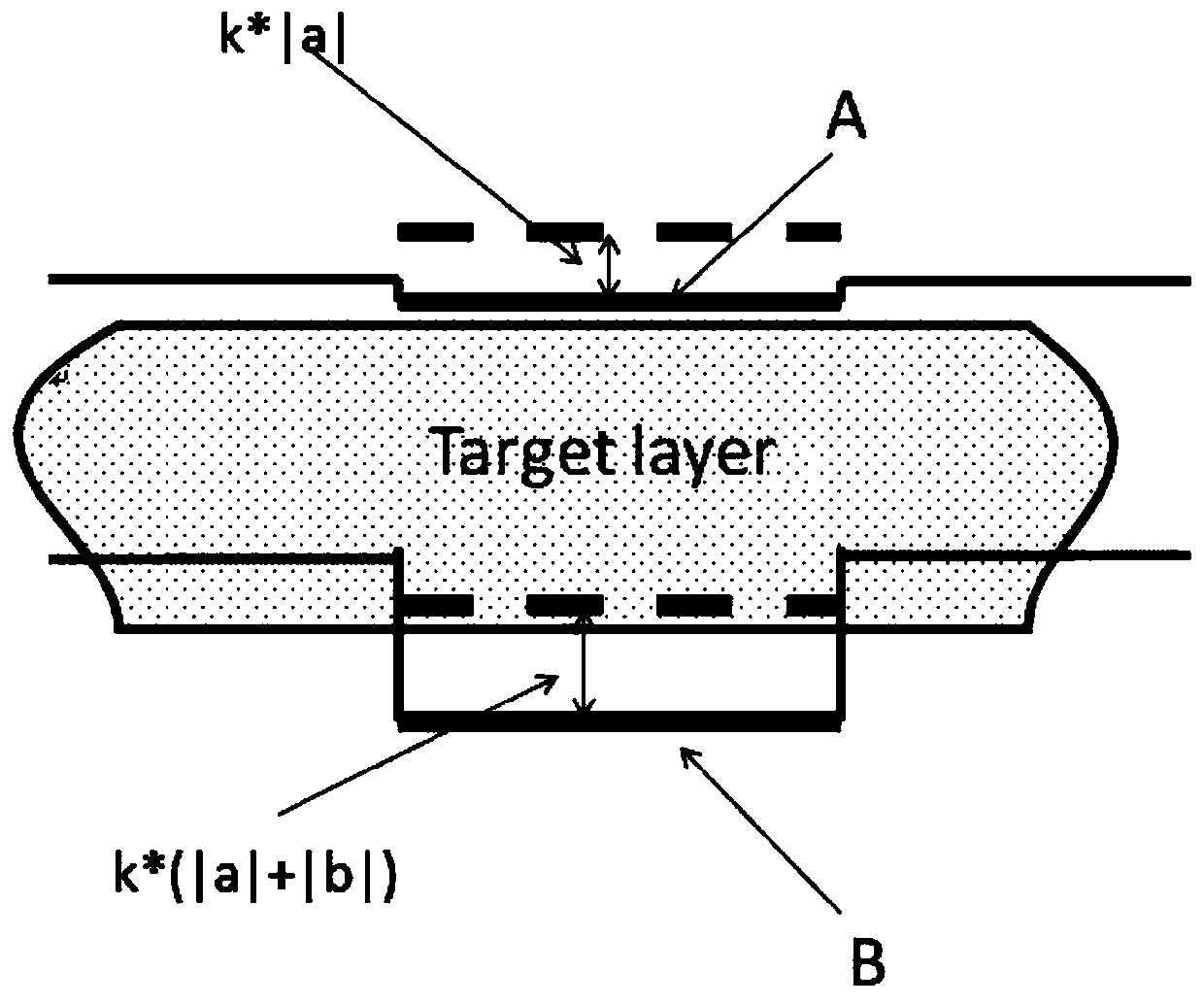

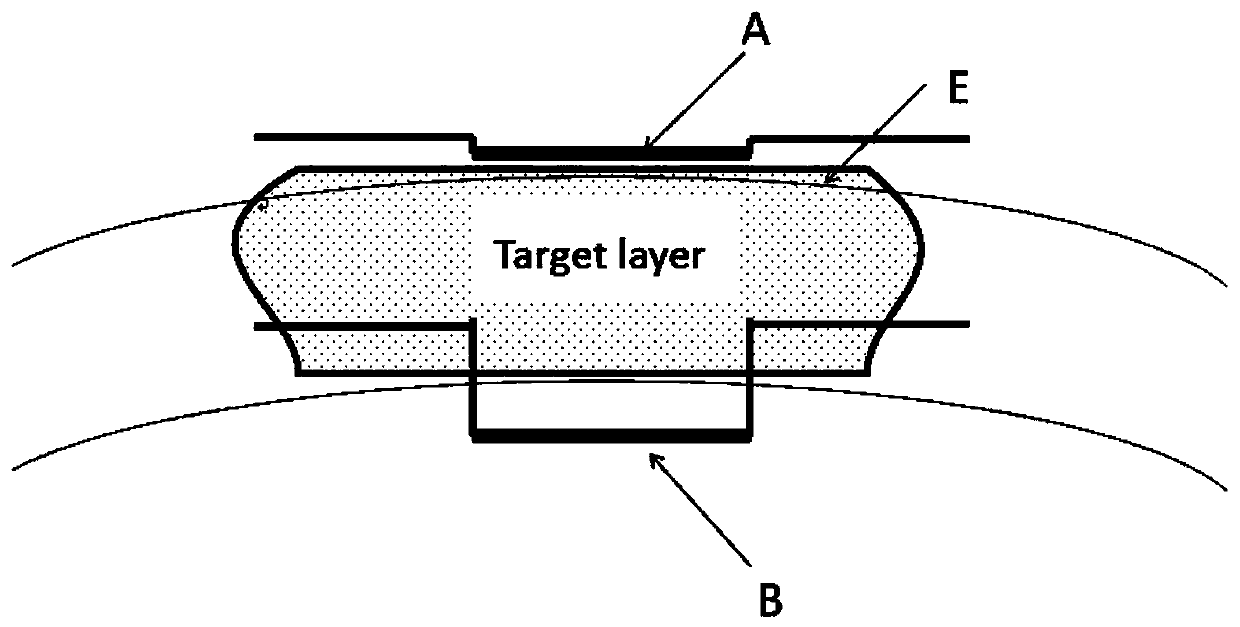

[0057] continue to combine Figure 1-Figure 3 As shown, the first embodiment of the method for correcting the proximity ef...

no. 2 example

[0060] The present invention provides a second embodiment of a model-based optical proximity effect correction method, which includes the following steps:

[0061] S1, based on the model, the graphic simulation on the current mask plate is formed into a photoresist profile;

[0062] S2. Determine the edge position error according to the positional relationship between the photoresist profile and the corresponding edge of the target pattern; determine the edge position error of the photoresist profile inside the target pattern as negative, and judge the edge position error of the photoresist profile outside the target pattern is positive; wherein, the edge position error is equal to the distance between the target pattern and the photoresist profile;

[0063] S3, screening out opposite sides whose edge position errors in the graph to be corrected are positive and negative respectively;

[0064] S4, calculate and screen out the pre-movement and actual movement of the opposite s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com