Control cabinet with good heat dissipation performance

A technology of heat dissipation performance and control cabinet, applied in the field of control cabinet, can solve the problem of easy intrusion heat dissipation performance, etc., to achieve the effect of strengthening heat dissipation effect, strengthening heat dissipation efficiency, and increasing heat dissipation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

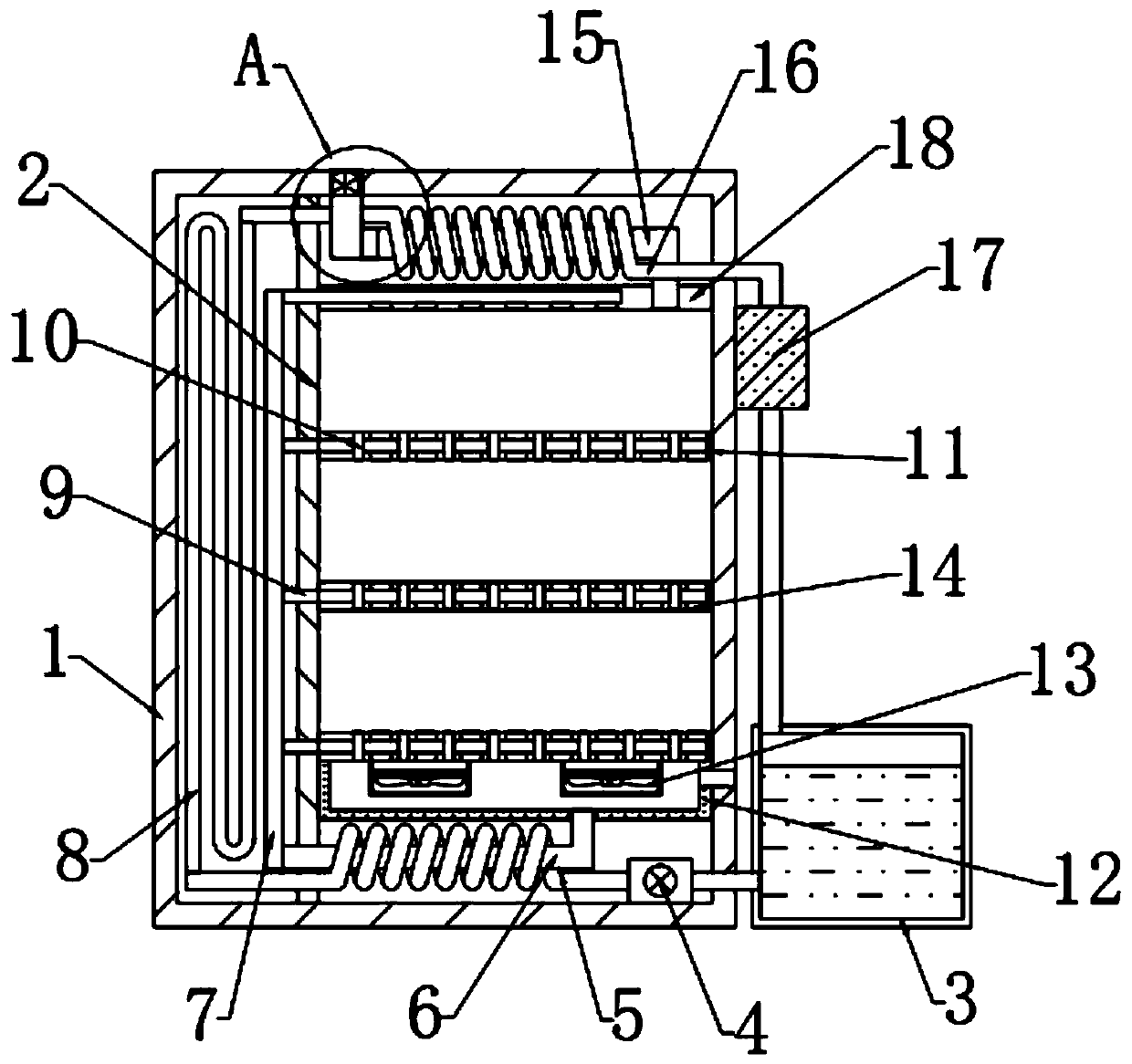

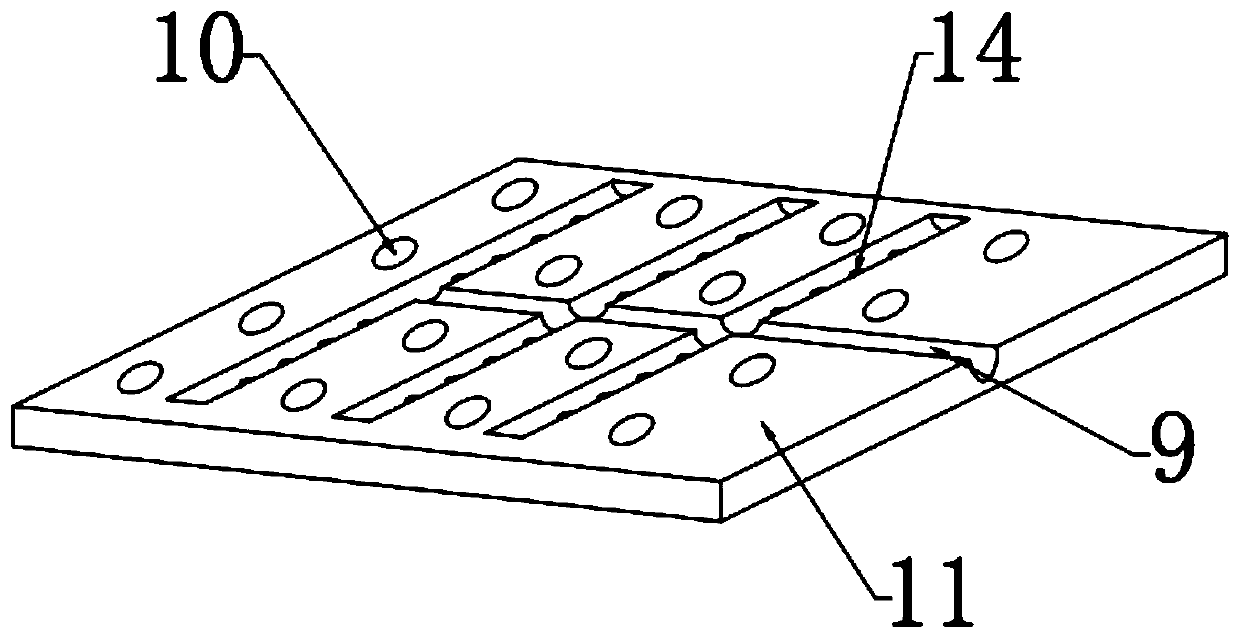

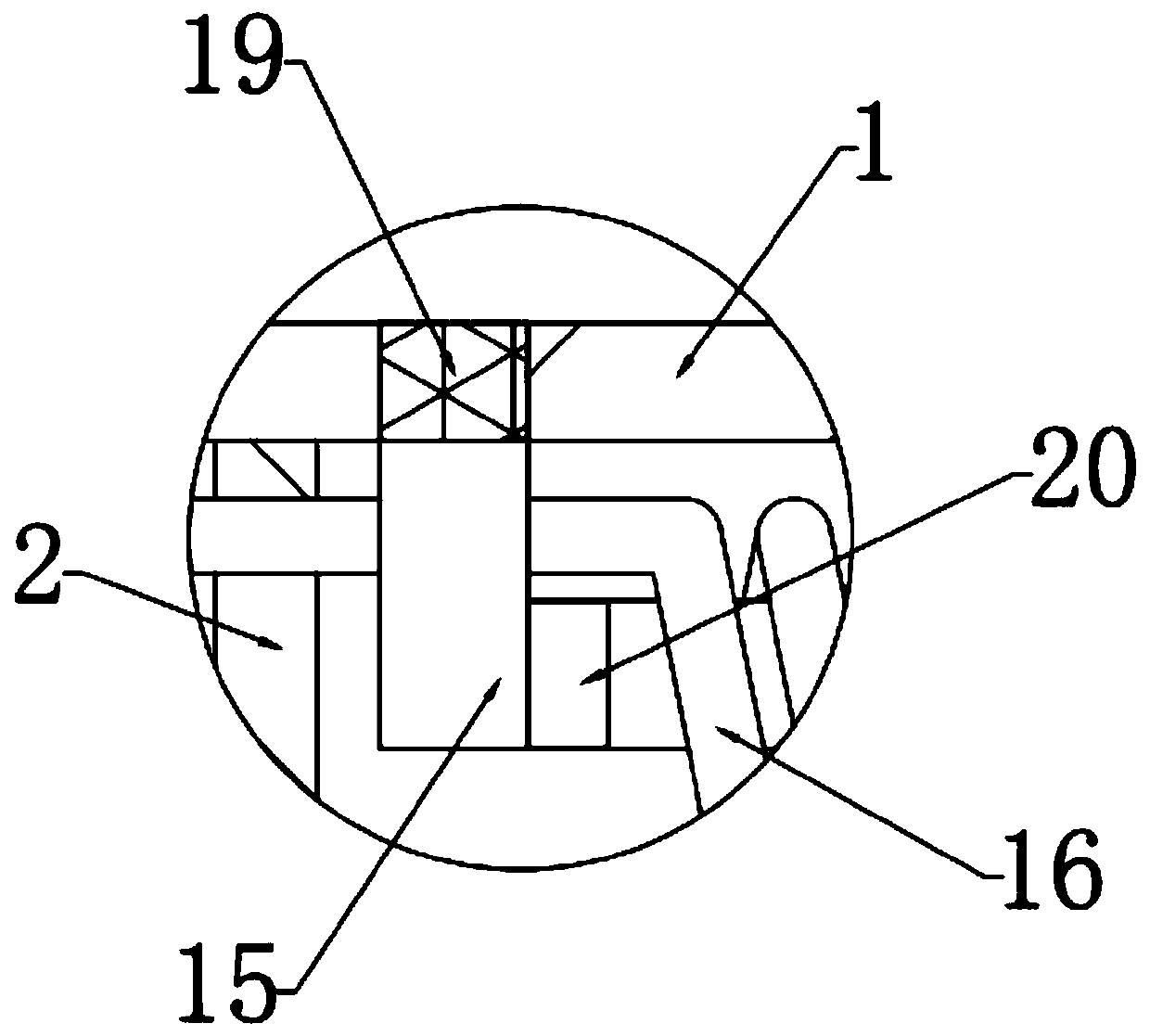

[0028] see Figure 1~3 , in an embodiment of the present invention, a control cabinet with good heat dissipation performance, including a cabinet body 1, is characterized in that a partition 2 is fixed vertically inside the cabinet body 1, and the right side of the partition board 2 is connected to the cabinet body 1, a top plate 18 is horizontally arranged, and several layers of placing plates 11 are horizontally arranged on the lower side of the top plate 18, and a cooling box 12 is fixedly connected to the lower side of the placing plate 11 on the bottom side, and the right side of the cooling box 12 is set There is a ventilation pipe passing through the cabinet body 1, a first cooling mechanism is arranged on the lower side of the heat dissipation box 12, a second cooling mechanism is arranged on the upper side of the top plate 18, and a cooling mechanism is arranged on the left side of the partition plate 2.

Embodiment 2

[0030] In this embodiment, the first cooling mechanism includes a water tank 3, an air outlet pipe 6, a first cooling pipe 5 and a fan 13, the water tank 3 is arranged on the right side of the cabinet body 1, and the air outlet pipe 6 is fixedly connected with a heat dissipation At the bottom of the tank 12, the other end of the air outlet pipe 6 passes through the partition 2 and is connected to the air delivery pipe 7. A first cooling pipe 5 is arranged on the outside of the air outlet pipe 6, and a water pump passes between the input end of the first cooling pipe 5 and the water tank 3. 4 connection, the inside top of the heat dissipation box 12 is fixedly connected with a fan 13.

[0031] In this embodiment, the second cooling mechanism includes an air inlet pipe 15 and a second cooling pipe 16, the air inlet pipe 15 is arranged on the upper side of the top plate 18, the input end of the air inlet pipe 15 is connected to the cabinet body 1, and the air inlet pipe 15 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com