A turning mechanism and turning method suitable for an assembled underpass tunnel

A flipping mechanism and prefabricated technology, applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of low flipping efficiency, easy damage to prefabricated components, and great construction hazards, so as to reduce prefabrication costs, facilitate assembly and construction, and ensure structural integrity. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

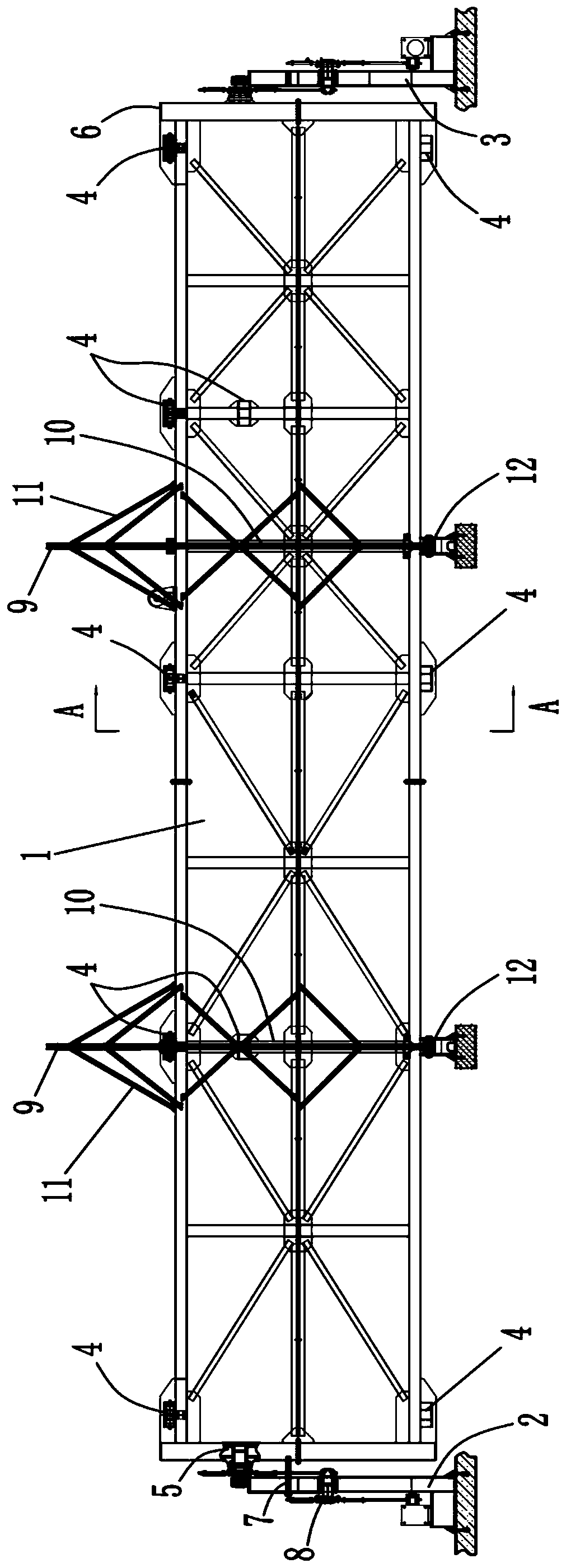

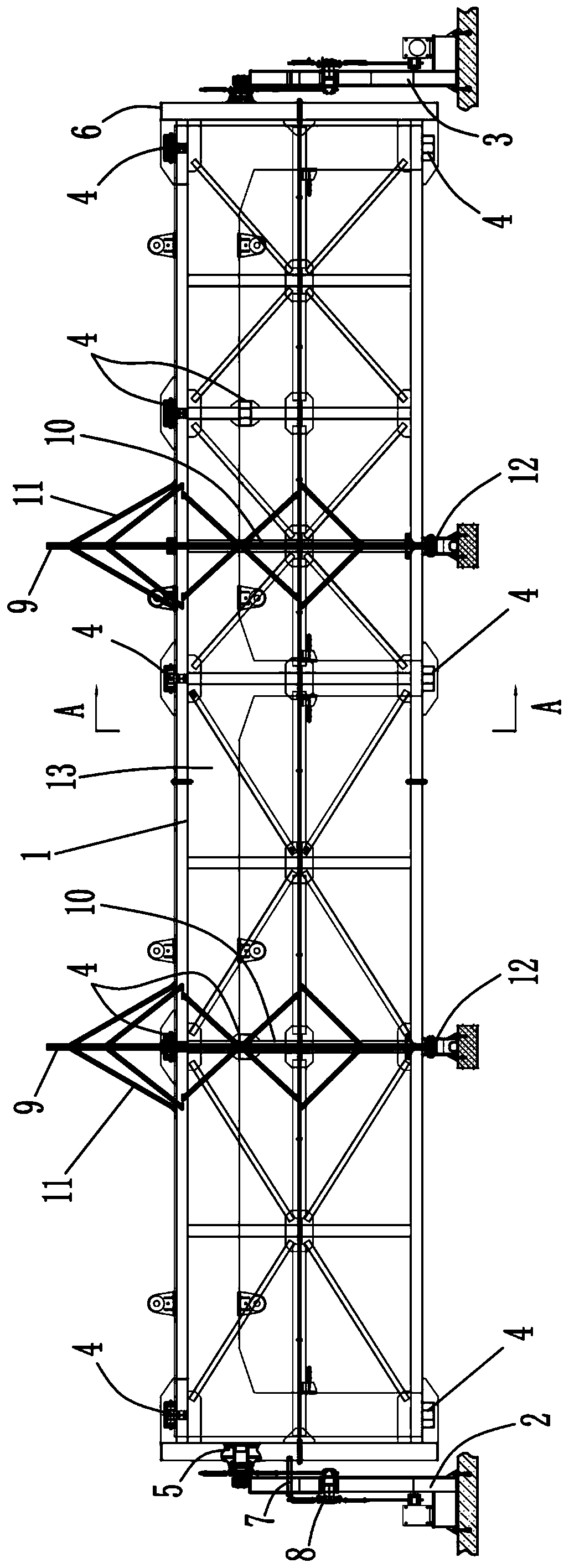

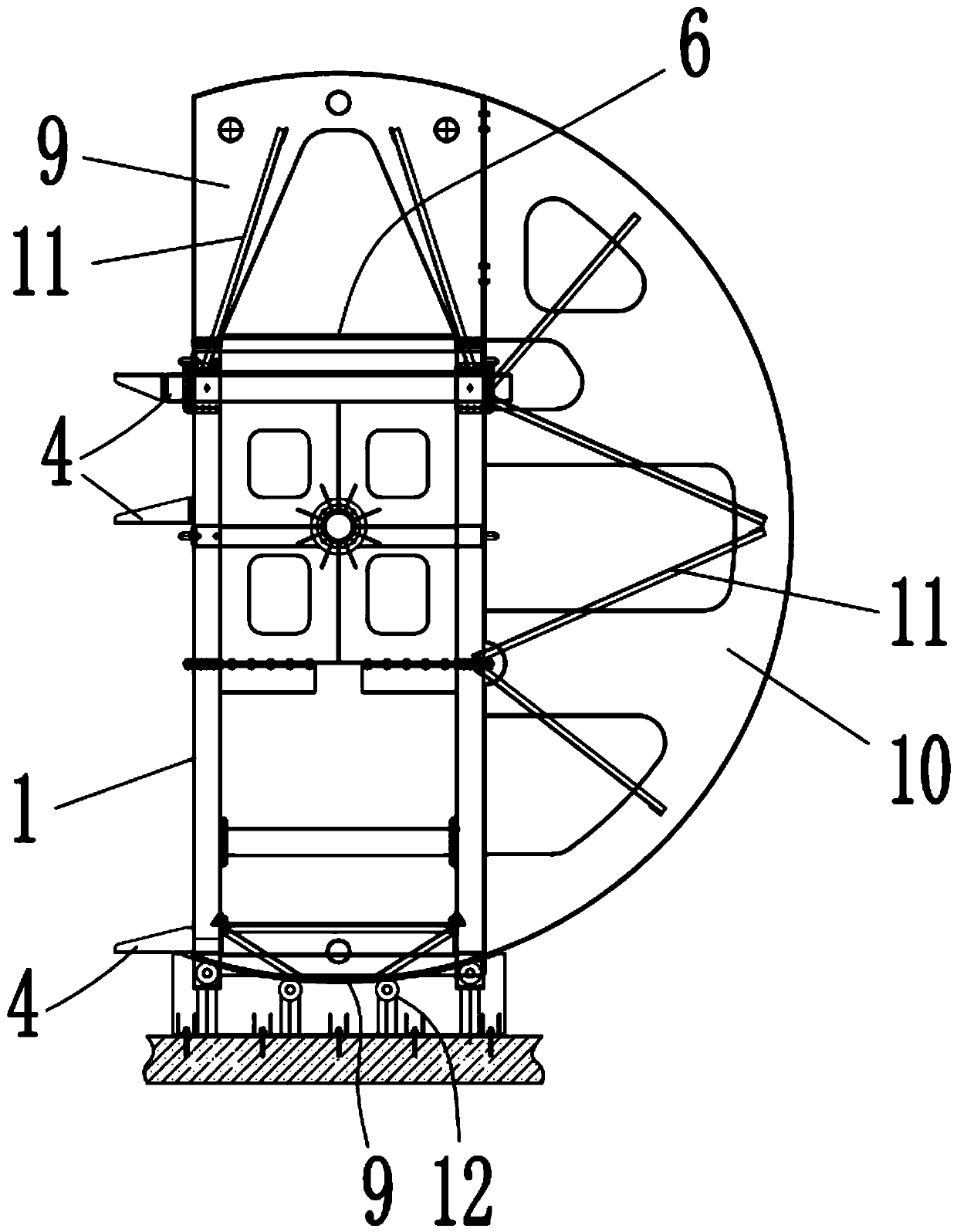

[0036] Example 1, such as Figure 1-3 Shown:

[0037] A turning mechanism suitable for a fabricated underpass tunnel, comprising a clamping part 1 for clamping the prefabricated member 13 and a first supporting seat 2 and a second supporting seat 3 for supporting the clamping part 1, so The clamping member has a clamping space through which the prefabricated member 13 can penetrate vertically. The first support base 2 and the second support base 3 are arranged opposite to each other and rotate and cooperate with the support member. A supporting base 2 and / or a second supporting base 3 is also provided with a driving member for driving the clamping member 1 to rotate, and a plurality of supporting rods passing through the clamping space are also provided on the clamping member 1 4. The support rod 4 is used to support the prefabricated member 13 in the vertical direction, and the support rod 4 is detachably connected to the clamping component 1.

[0038] In the turning mechanism o...

Embodiment 2

[0048] Example 2, such as Figure 1-3 Shown,

[0049] A method for prefabricating tunnel frame members using the above-mentioned turning mechanism,

[0050] Step 1. Design steps: In the design stage, divide the frame members of the tunnel to be constructed into W-frame and M-frame in the horizontal direction;

[0051] Step 2: Making the pouring mold: make W-frame pouring mold or M-frame pouring mold;

[0052] Step three, pouring: pouring the W-frame and M-frame in the W-frame pouring mold or M-frame pouring mold in step two;

[0053] Step four, component flip:

[0054] When the pouring mold is a W-frame pouring mold, hoist the poured M-frame into the clamping space of the turning mechanism, and then start the driving device of the turning mechanism to turn the clamping part 1 through 180°, so that the M-frame is installed form;

[0055] When the pouring mold is an M-frame pouring mold, hoist the poured W-shaped frame into the holding space of the turning mechanism, and then start the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com