Cable comprising crosslinked layer obtained from polymer composition

A technology of polymer and cross-linked layer, applied in insulated cables, cable/conductor manufacturing, cables, etc., can solve problems such as cross-linked products that are not suitable for the production of halogen-free polymers, and improve aging stability and electrical stability. high degree of cross-linking, and the effect of improving aging stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

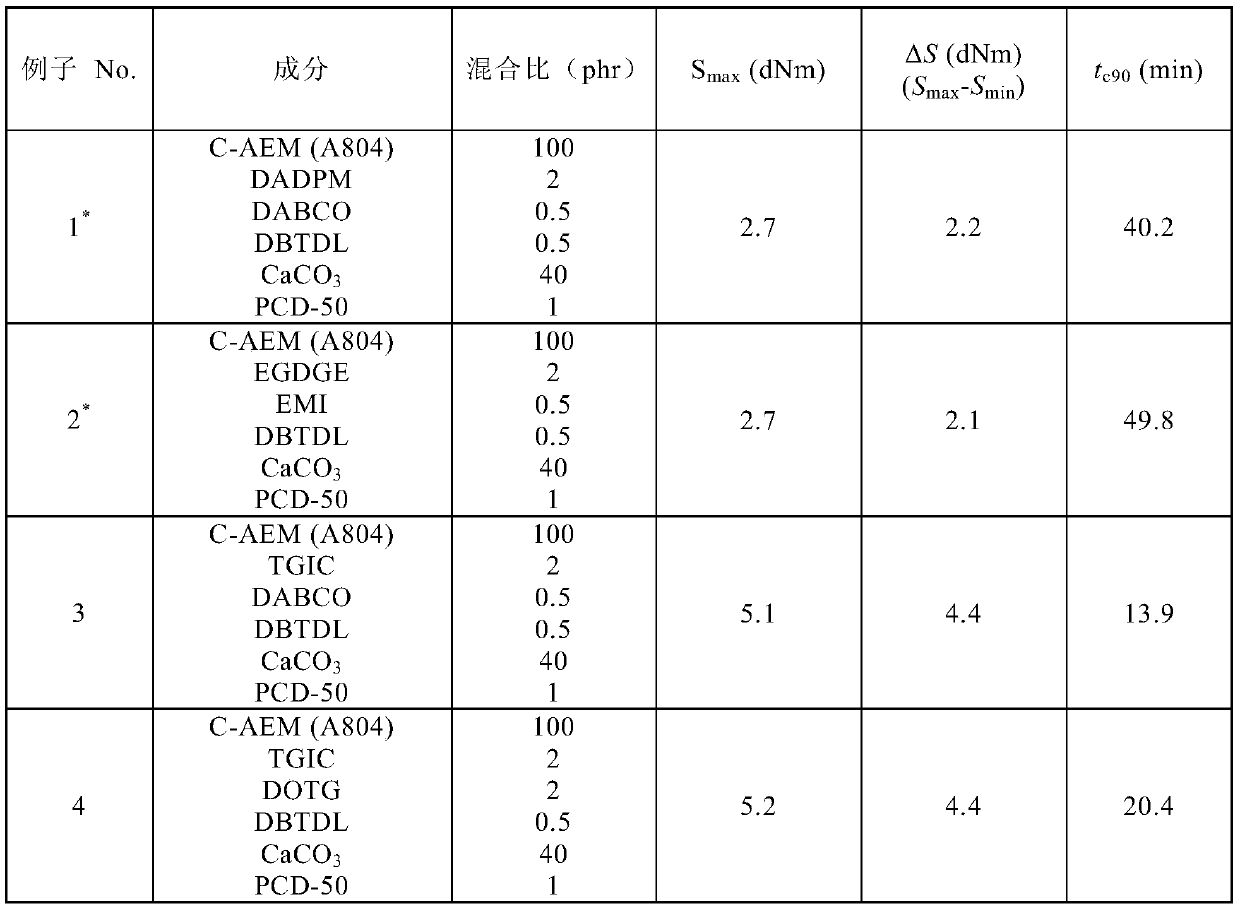

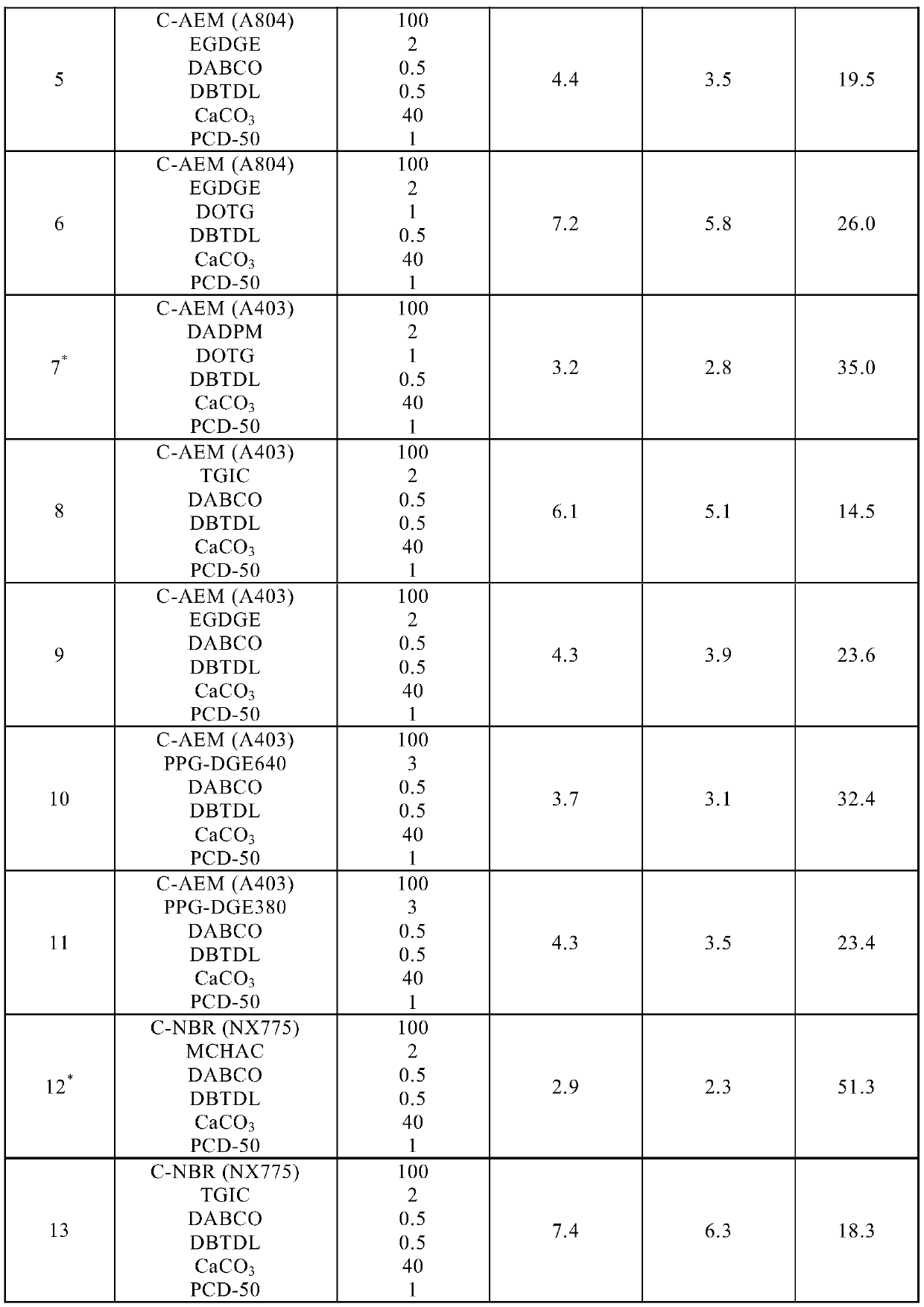

[0103] Hereinafter, the present invention is described in further detail in the following examples, which are not intended to limit the scope of the present invention in any way. In addition, it is apparent that various modifications to the disclosed embodiments may be made by those skilled in the art and such modifications are intended to be within the scope of the invention.

[0104] Preparation of the polymer composition according to the invention and its cross-linked product and determination of its cross-linking properties

preparation example

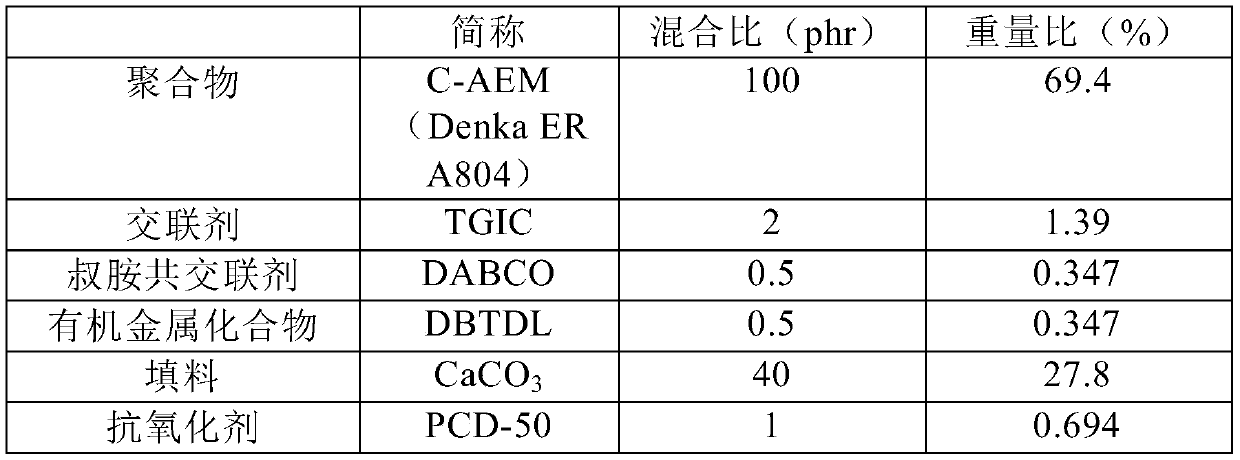

[0106] At 80°C, a carboxyl-containing ethylene-acrylate copolymer (C-AEM, Denka ERA804, containing about 2% by weight of carboxyl groups), triglycidyl isocyanurate (TGIC, I0428 , Tokyo Chemical Industry Co.), 1,4-diazabicyclo [2.2.2] octane (DABCO, D0134, Tokyo Chemical Industry Co.), dibutyltin dilaurate (DBTDL, Dabco T-12, OHSUNG polytec Co .), PCD-50 (Rhenogran PCD-50, RheinChemie) and CaCO 3 (Hydorcarb 95T, Omya International AG) was mixed for 10 minutes at the mixing ratio shown in Table 1 below to prepare a polymer composition according to the present invention. The crosslinking properties, such as minimum and maximum torque values (S min and S max ) and the time required to reach 90% of the maximum torque value (t c90 ). Then, at the predetermined crosslinking temperature (180°C) and under a pressure of about 30 bar, at the t determined above c90 Inside, the polymer composition thus prepared was molded and crosslinked using a compression mold, thereby preparing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com