Fabricated light steel energy-dissipation wall with flat plate soft steel dampers and connecting mode of fabricated light steel energy-dissipation wall

A mild steel damper and prefabricated technology, applied in the direction of walls, protective buildings/shelters, building components, etc., can solve the problems of insufficient lateral force resistance, poor seismic performance, etc., to improve energy consumption capacity and system optimization. , the effect of saving design and development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

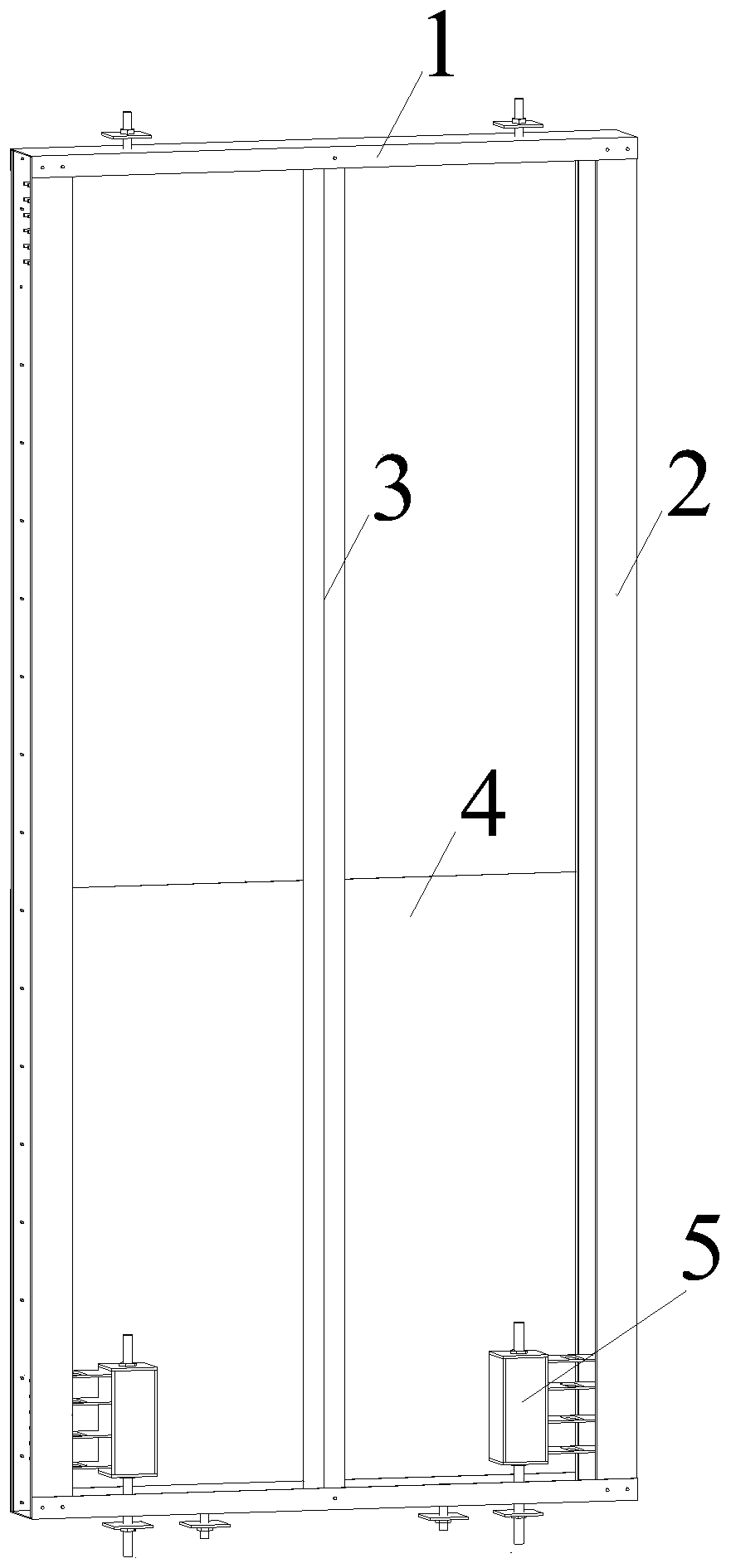

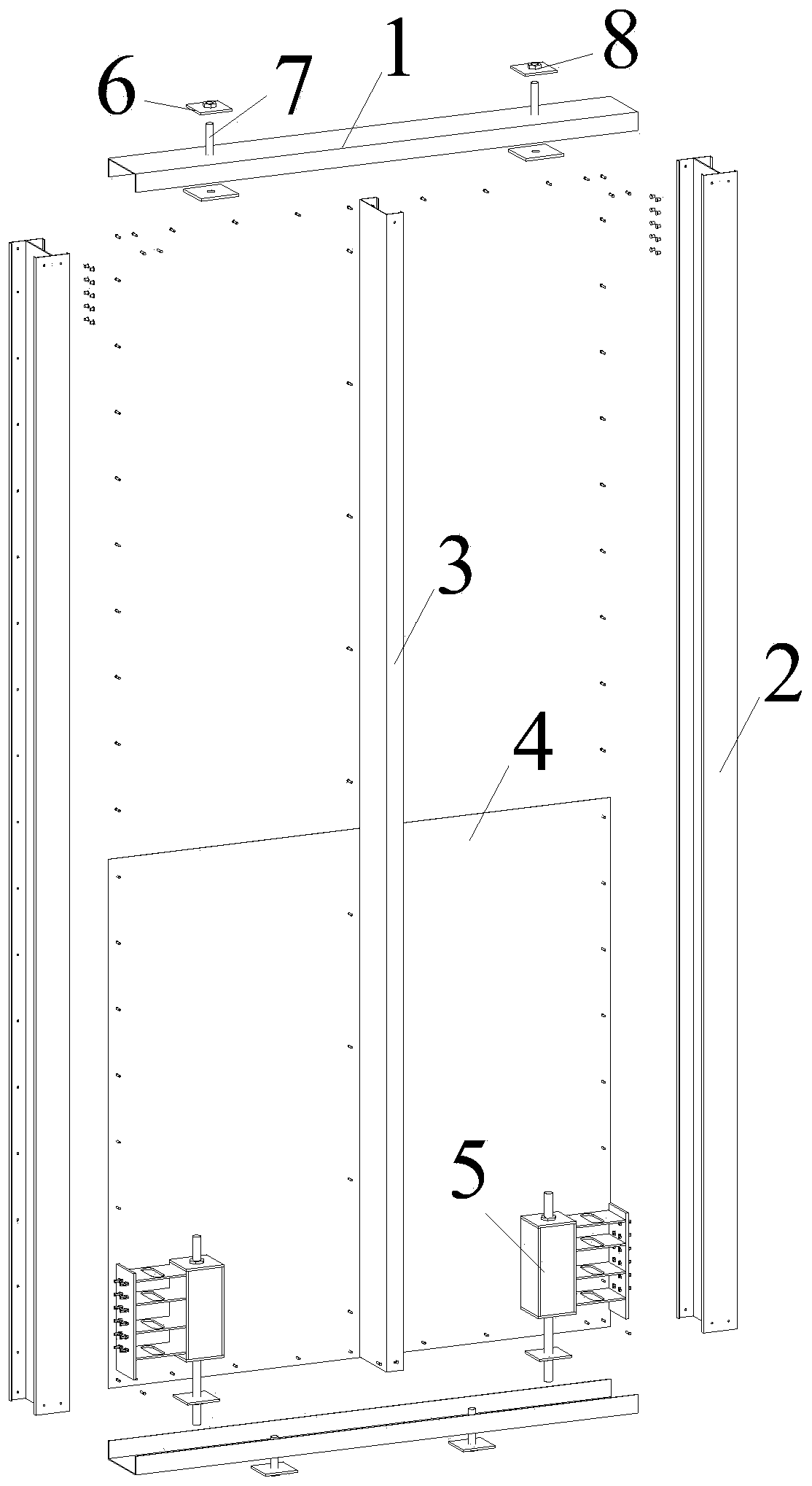

[0032] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and the technical solution of the description:

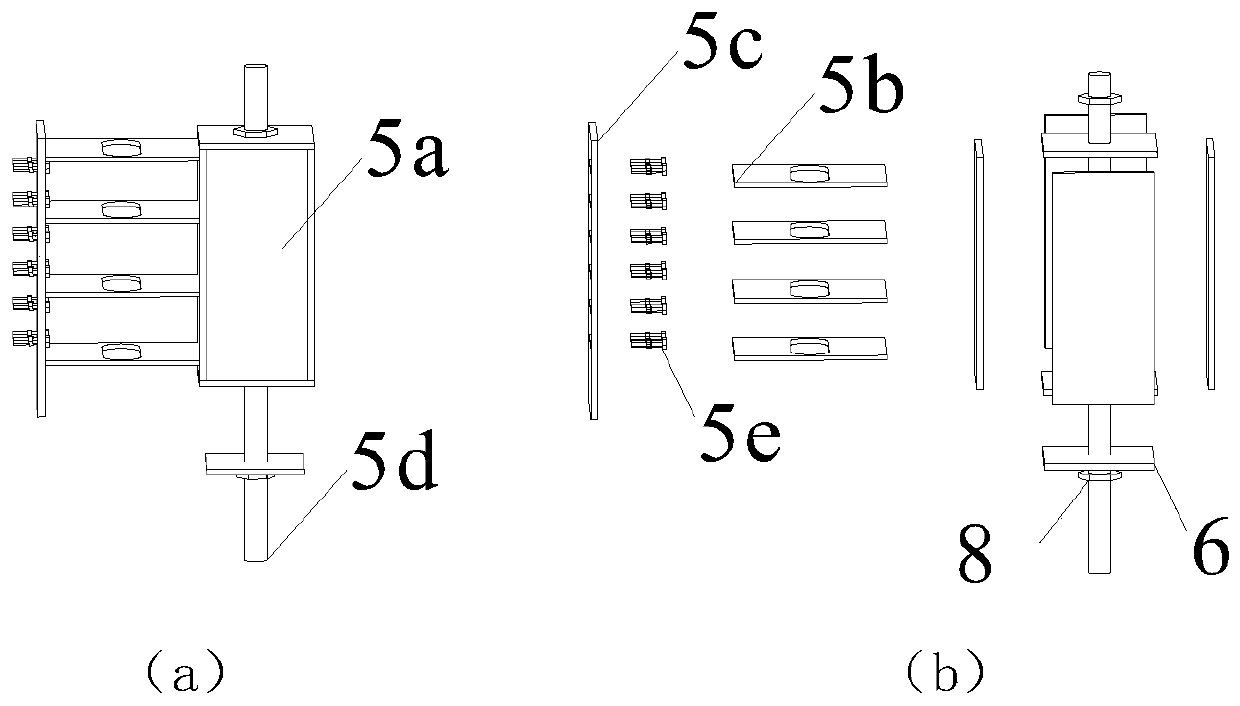

[0033] Manufacturing method of flat mild steel damper:

[0034] Step 1: Design the dimensions according to the drawings, refer to the attached image 3 , 4 , 5, blanking and processing the two types of steel plates required for the pull-out connection support 5a in the flat mild steel damper 5, the low yield point steel plate with a hole in the middle required for the energy-dissipating mild steel 5b, and the connecting steel plate 5c Required steel plate and threaded long screw rod 5d;

[0035] Step 2: Connect the blanked and processed parts according to the designed connection method (the steel plate of the pull-out connection support 5a is connected by welding, the energy-dissipating mild steel 5b is connected with the pull-out connection support 5a and the connection steel plate 5c ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com