Main return air duct reconstruction method suitable for concentrated return air in downhole

A return air duct and centralized technology, applied in separation methods, chemical instruments and methods, ventilation of mines/tunnels, etc., can solve problems such as no total air return duct, achieve short renovation period, save engineering and equipment investment, and be convenient The effect of ventilation management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

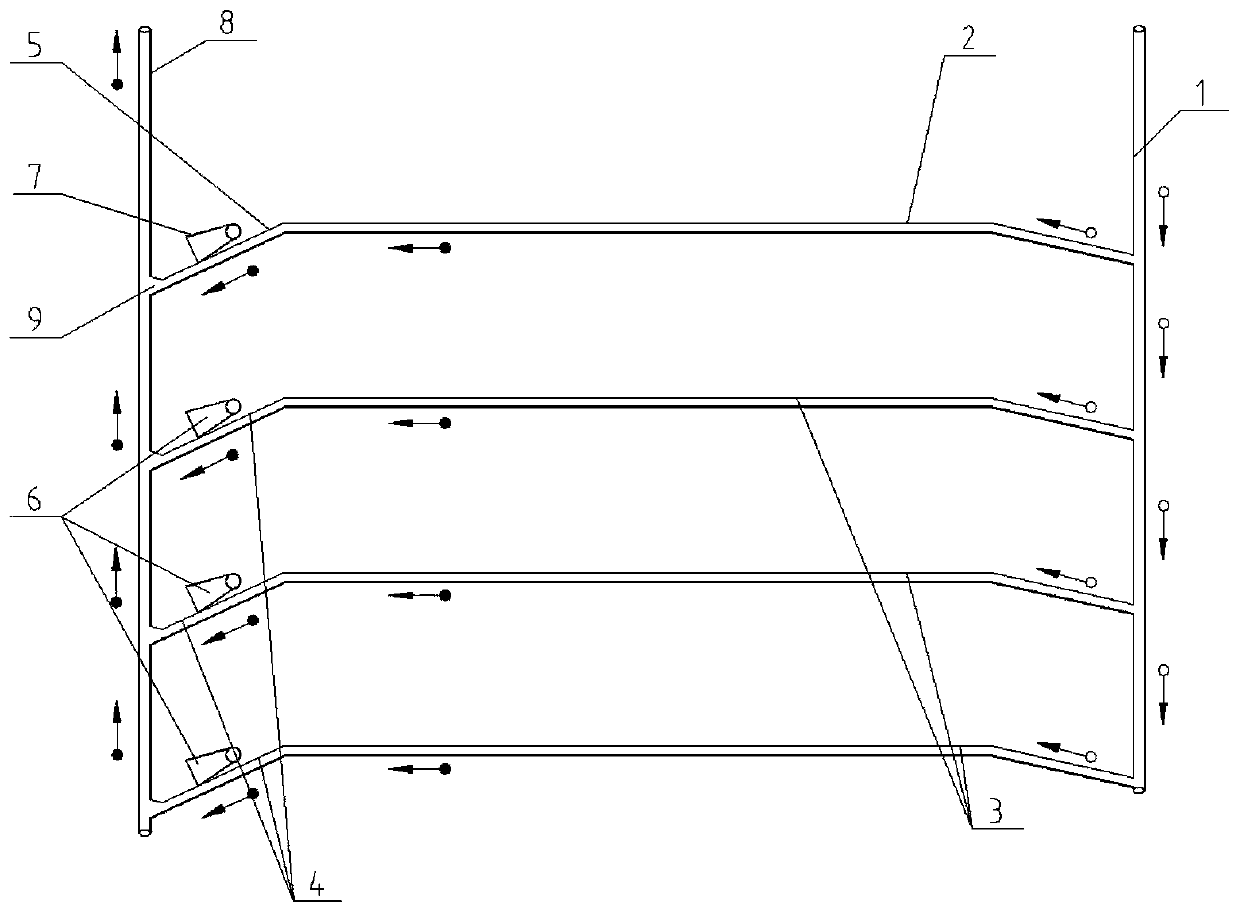

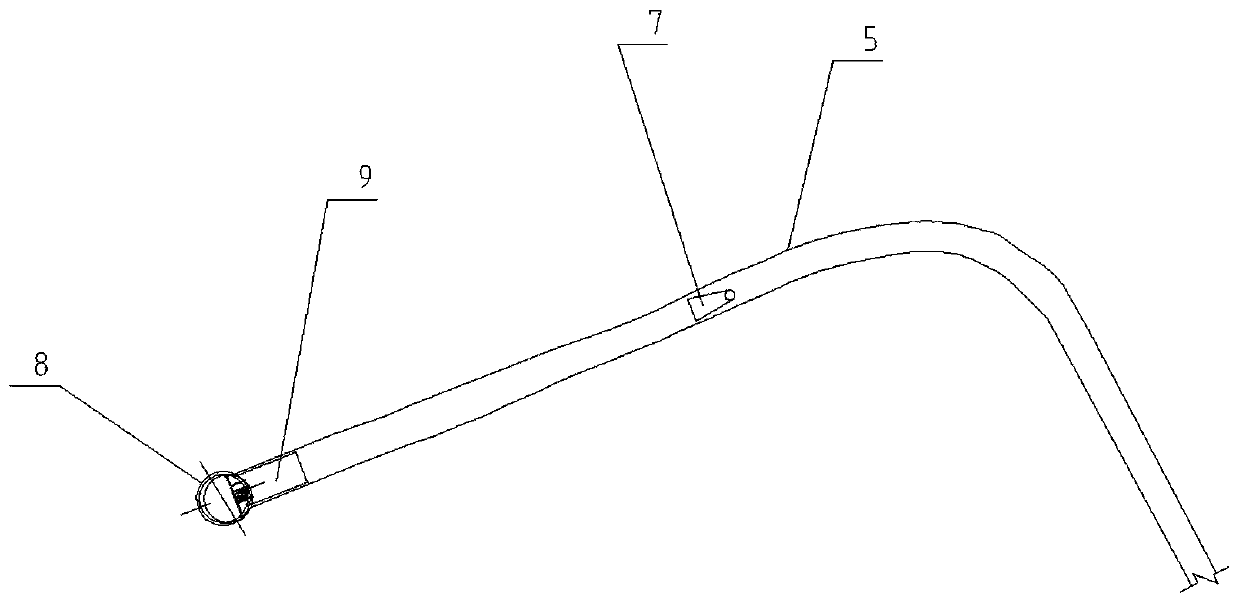

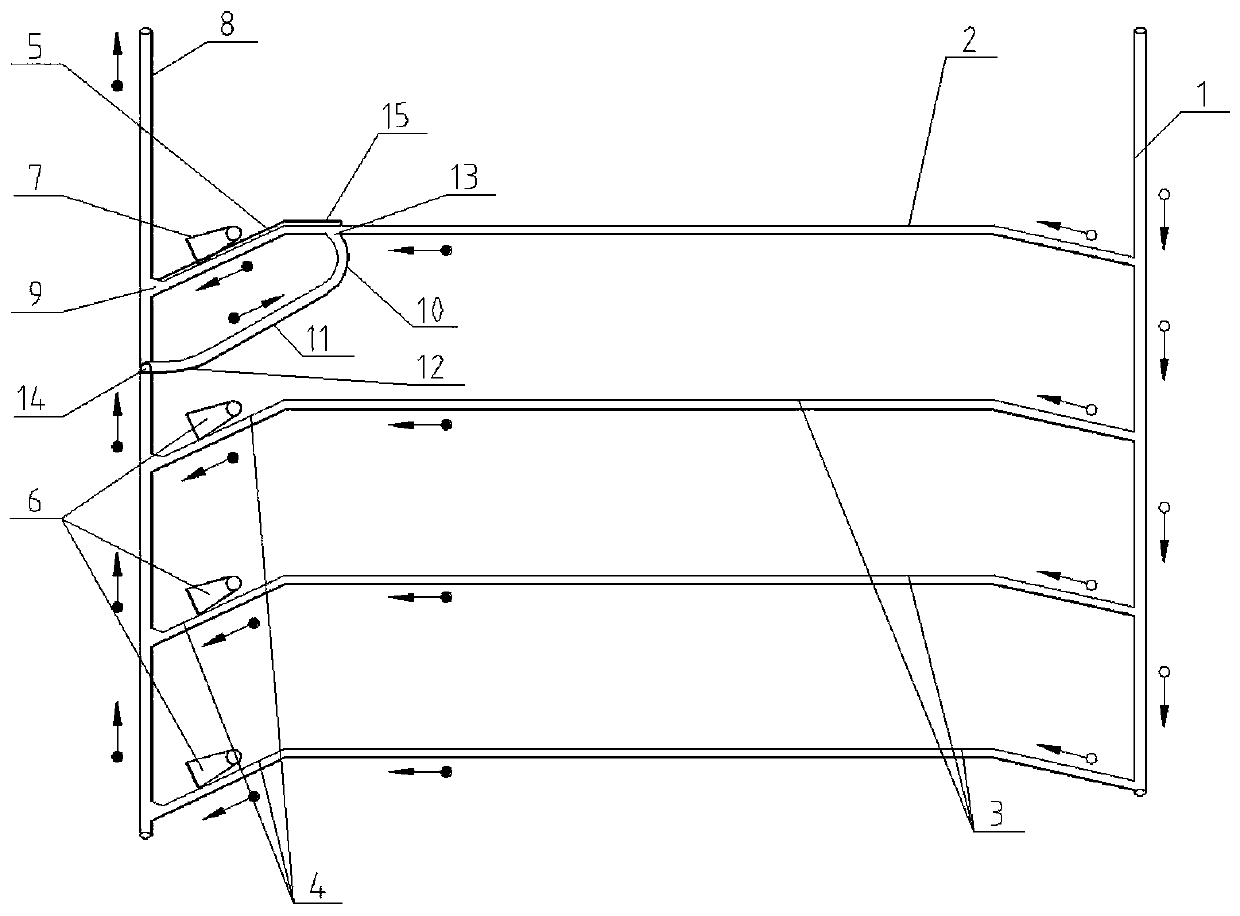

[0055] From figure 1 and figure 2 It can be seen that the original ventilation system applicable to the underground concentrated air return of the present invention includes an air inlet shaft 1, the shallowest middle section air inlet lane 2, the deep middle section air inlet lane 3, the deep middle section return air stone gate 4, the shallowest middle section air inlet lane Wind stone door 5, deep return air Shimen machine station fan 6, the shallowest middle section return air Shimen machine station fan 7 and return air shaft 8, the shallowest middle section air inlet lane 2 is located in the shallowest part of the mine, and the deepest middle section air inlet lane 3 Located below the shallowest middle air inlet lane 2, the air inlet ends of the shallowest middle air inlet lane 2 and the deep middle air inlet lane 3 are connected to the air inlet shaft 1, and the return air end of the shallowest middle air inlet lane 2 The return air shaft 8 is communicated with the ret...

Embodiment 2

[0086] From Figure 10 to Figure 12 It can be seen that the difference between this embodiment and Embodiment 1 is that the platform of this embodiment adopts a reinforced concrete beam-slab structure, the concrete strength grade is not less than C30, the platform 19 includes a main beam 20 and a secondary beam 21, and the main beam 20 Excavate the existing well wall 22 of the air return shaft to form a beam nest 29, and the size of the beam nest 29 is determined on site according to the specifications of the main beam 20;

[0087] The main beam 20 and the secondary beam 21 adopt a well-shaped arrangement, the main beam 20 is arranged horizontally, and the secondary beam 21 is arranged vertically, or the main beam 20 is arranged longitudinally, and the secondary beam 21 is arranged horizontally. The distance between the main beam 20 and the secondary beam 21 is the same, and the distance range 0.8-1.5m; concrete is poured around the main beam 20 and the secondary beam 21 to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com