Turbine rotor blade

A technology of turbine rotors and blades, which is applied to the supporting elements of blades, engine elements, machines/engines, etc., can solve the problems of inability to meet the needs of engine use, short lasting life of high-pressure turbine rotor blades, etc., to improve maturity and service life. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

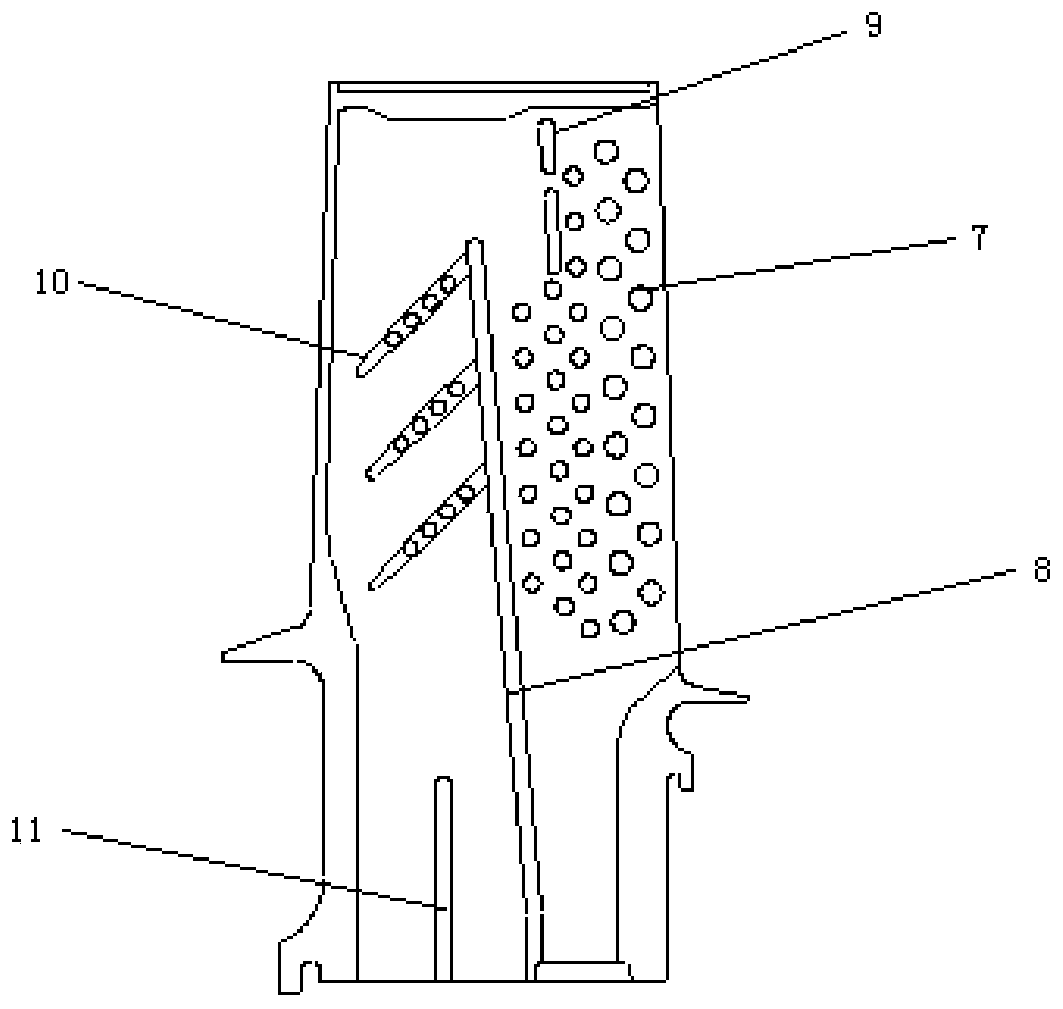

[0019] Below, combine figure 1 , figure 2 , image 3 , the present invention will be further described in detail through specific embodiments. The following implementations are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

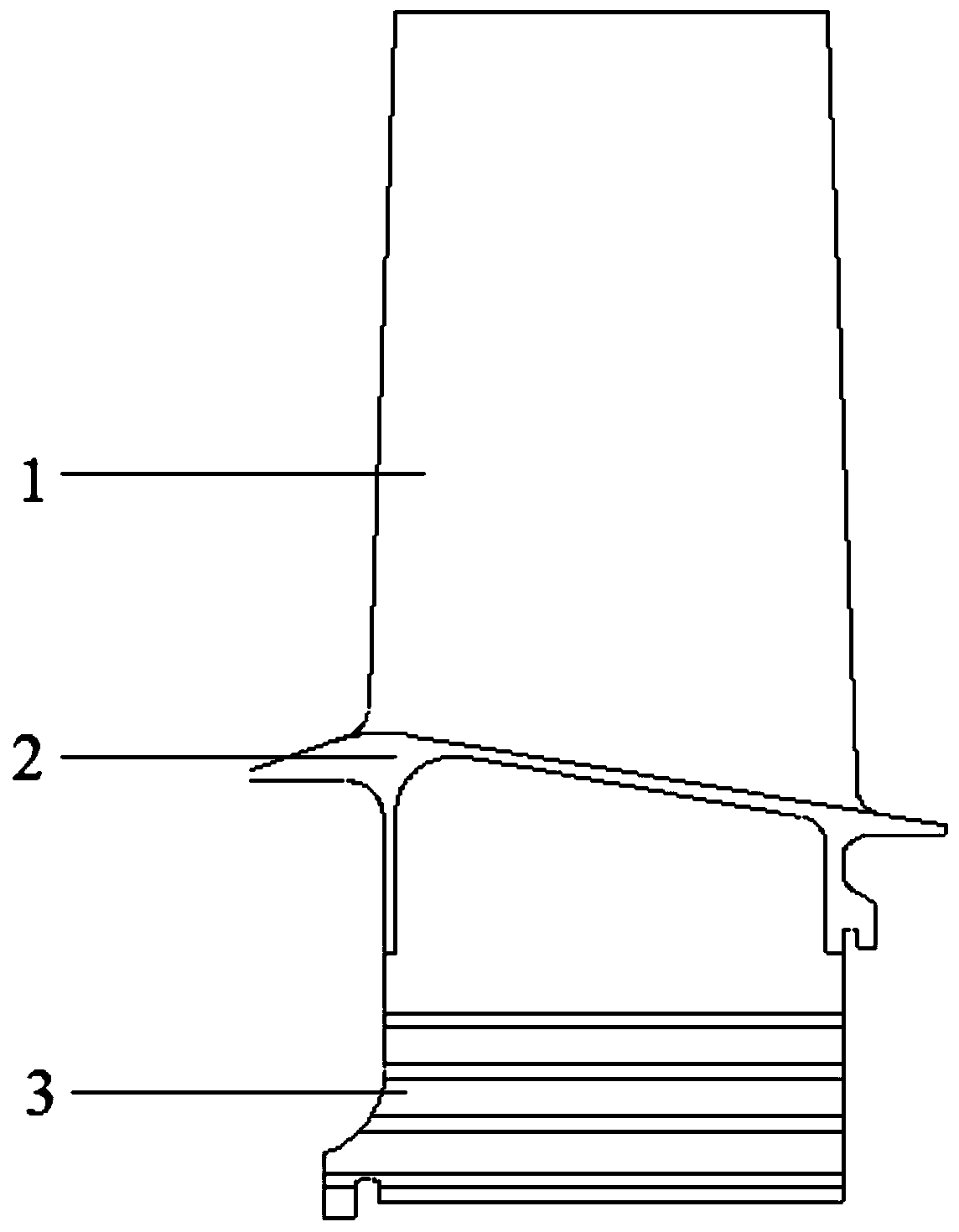

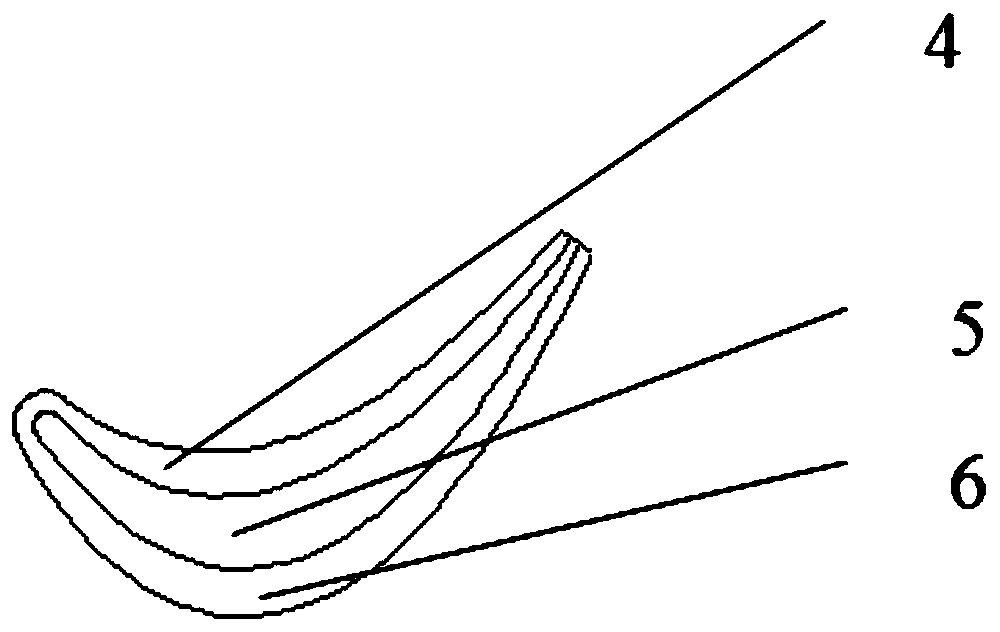

[0020] Depend on figure 1 It can be seen that a turbine rotor blade made of DD32 single crystal alloy according to the present invention includes a blade body 1, an edge plate 2, and a tenon 3, and is a hollow cast blade, and the blade body part is divided into a blade basin 4, an inner cavity 5, a blade The back is 6, and the trailing edge is in the form of opening splits. The present invention has taken following technical scheme:

[0021] Among them, in order to improve the long-lasting life of the blade, the material of the blade is designed with DD32 single-crystal alloy, which utilizes the characteristics of high-temperature resistance and long-lasting creep strength of DD32 single-crystal al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com