kW-grade supercritical carbon dioxide radial flow type turbine structure with flow dividing blades

A technology of splitting blades and carbon dioxide, which is applied in the direction of steam engine devices, stators, engine components, etc., can solve the problems that the blades are susceptible to large aerodynamic loads, the aerodynamic performance of the turbine is affected, and the safe operation of the turbine is unfavorable, so as to achieve a wide range of engineering application prospects , Improving the equal entropy efficiency of the turbine, and the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in more detail below in conjunction with accompanying drawing:

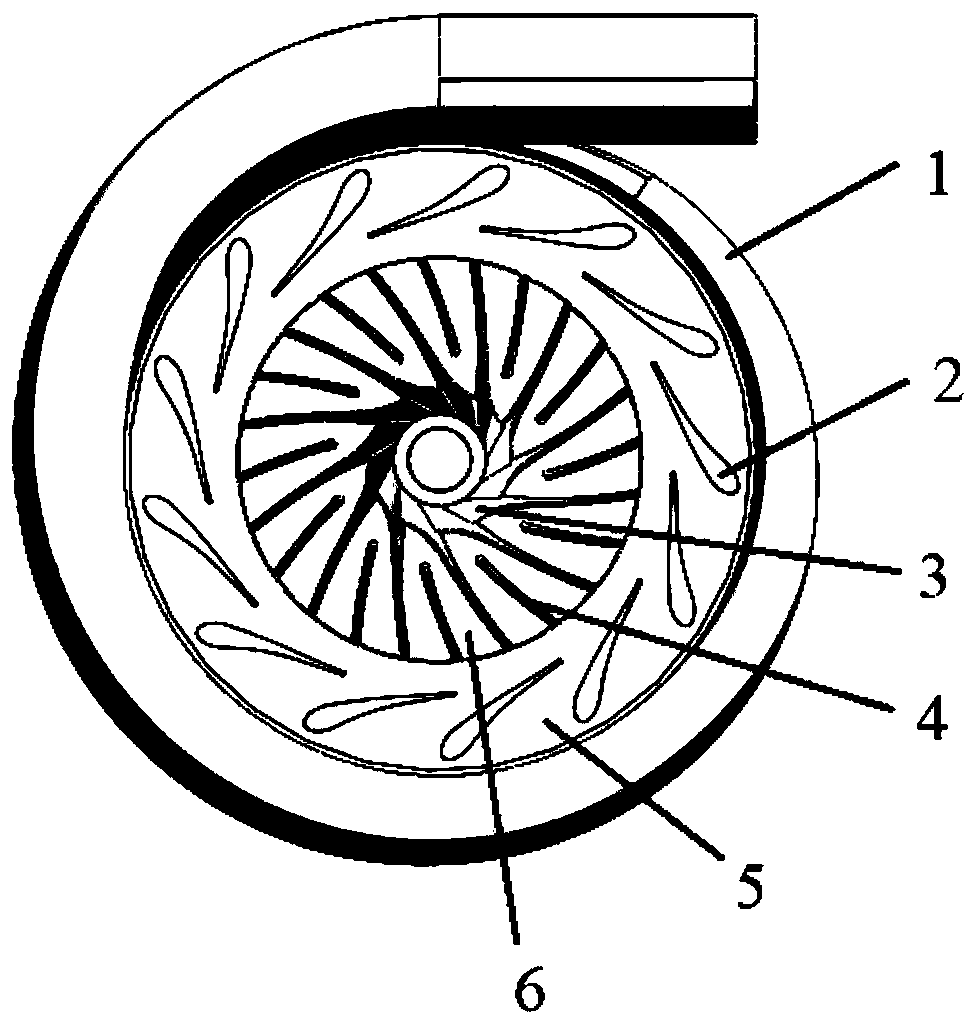

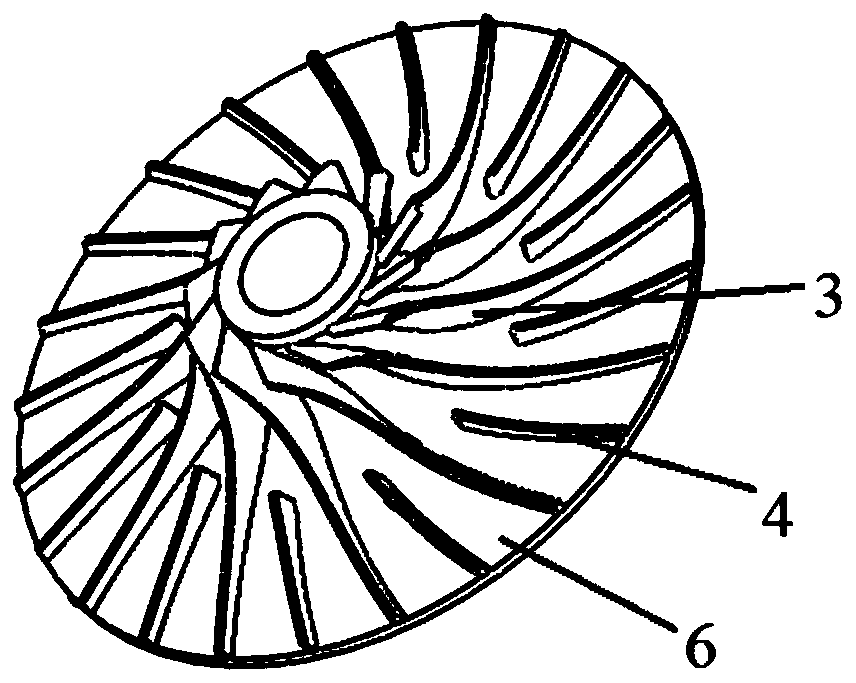

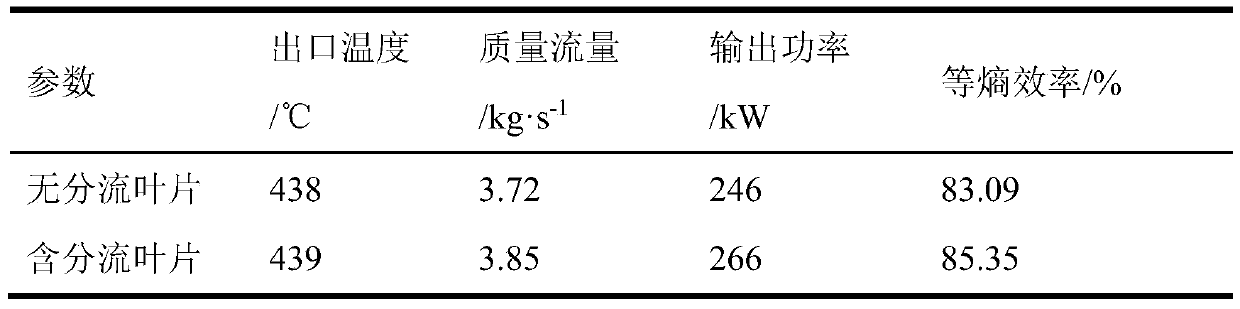

[0024] combine figure 1 and figure 2 , a kW-class supercritical carbon dioxide radial turbine structure with splitter blades provided by the present invention includes a volute 1, a stationary blade cascade 2, a movable blade cascade 3 and a splitter blade 4, wherein the splitter blade 4 is installed on the corresponding Between two adjacent movable blade cascades 3 , two adjacent stationary blade cascades 2 form a stationary blade cascade flow channel 5 , and a movable blade cascade flow channel 6 is formed between the movable blade cascade 3 and the splitter blade 4 . When working, the supercritical carbon dioxide working medium enters from the volute 1, and the gas is evenly distributed from the volute 1 to the flow channel 5 of the stator cascade. The pressure of the working medium gradually decreases in the flow channel 5 of the stationary blade cascade, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com