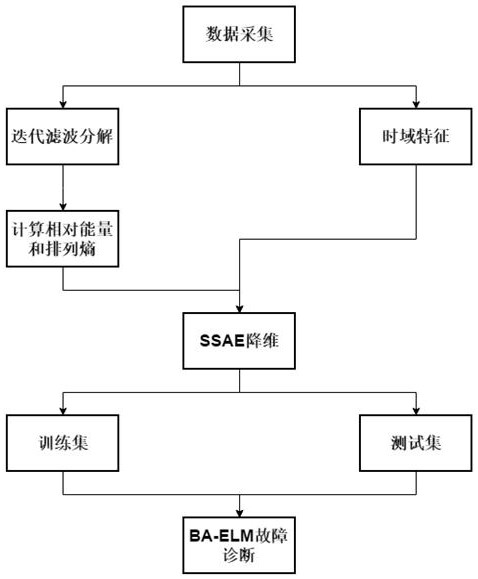

A Fault Diagnosis Method for Rolling Bearings Based on SSae and BA-ELM

A technology of BA-ELM and rolling bearings, applied in neural learning methods, testing of mechanical components, character and pattern recognition, etc., can solve the problem that data dimensionality reduction methods are difficult to retain the most effective features, signal processing methods lack robustness, and faults The problem of low degree classification accuracy can be solved, and the effect of suppressing mode aliasing, high efficiency and improving accuracy can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0129] This example uses 6205-2RS deep groove ball bearings, and the experimental platform includes a 2-horsepower motor, a torque sensor, a power meter and electronic control equipment. Use EDM technology to simulate single-point faults with fault depths of 0.18mm, 0.36mm, and 0.54mm, and collect the inner ring fault, outer ring fault, and rolling element fault signal pairs in normal state and different fault depths based on SSAE and BA-ELM The fault diagnosis method of rolling bearing is verified. Specific steps are as follows:

[0130] Step 1: Under the running state of the bearing, collect four kinds of bearing state time domain signals of normal, inner ring fault, outer ring fault and rolling element fault at the set sampling frequency, as shown in Table 1

[0131] Table 1. Rolling bearing failure experimental data

[0132]

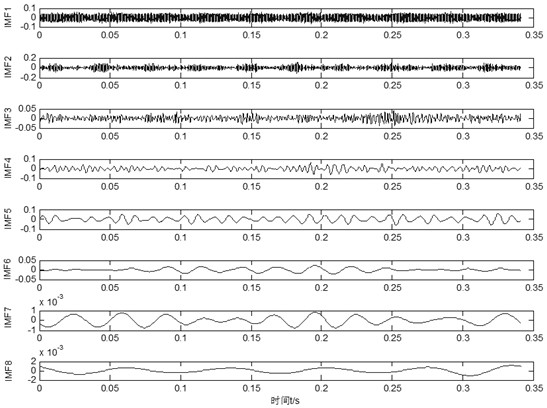

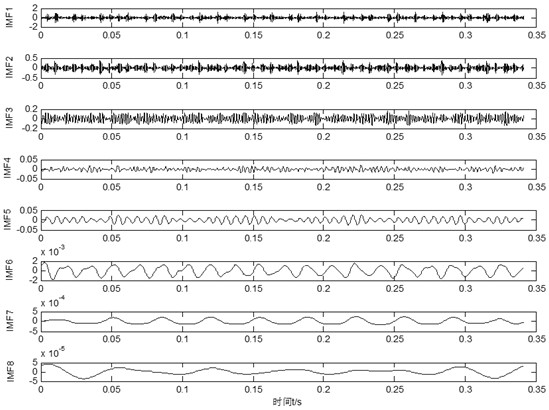

[0133] Step 2: Iteratively filter and decompose each group of signals to obtain a group of eigenmode components containing different time scale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com