Normal-pressure spraying test table

A spray test, atmospheric pressure technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of measurement deviation, effective processing, measurement error, etc., to optimize the bench structure, prevent liquid The effect of drop bounce and improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

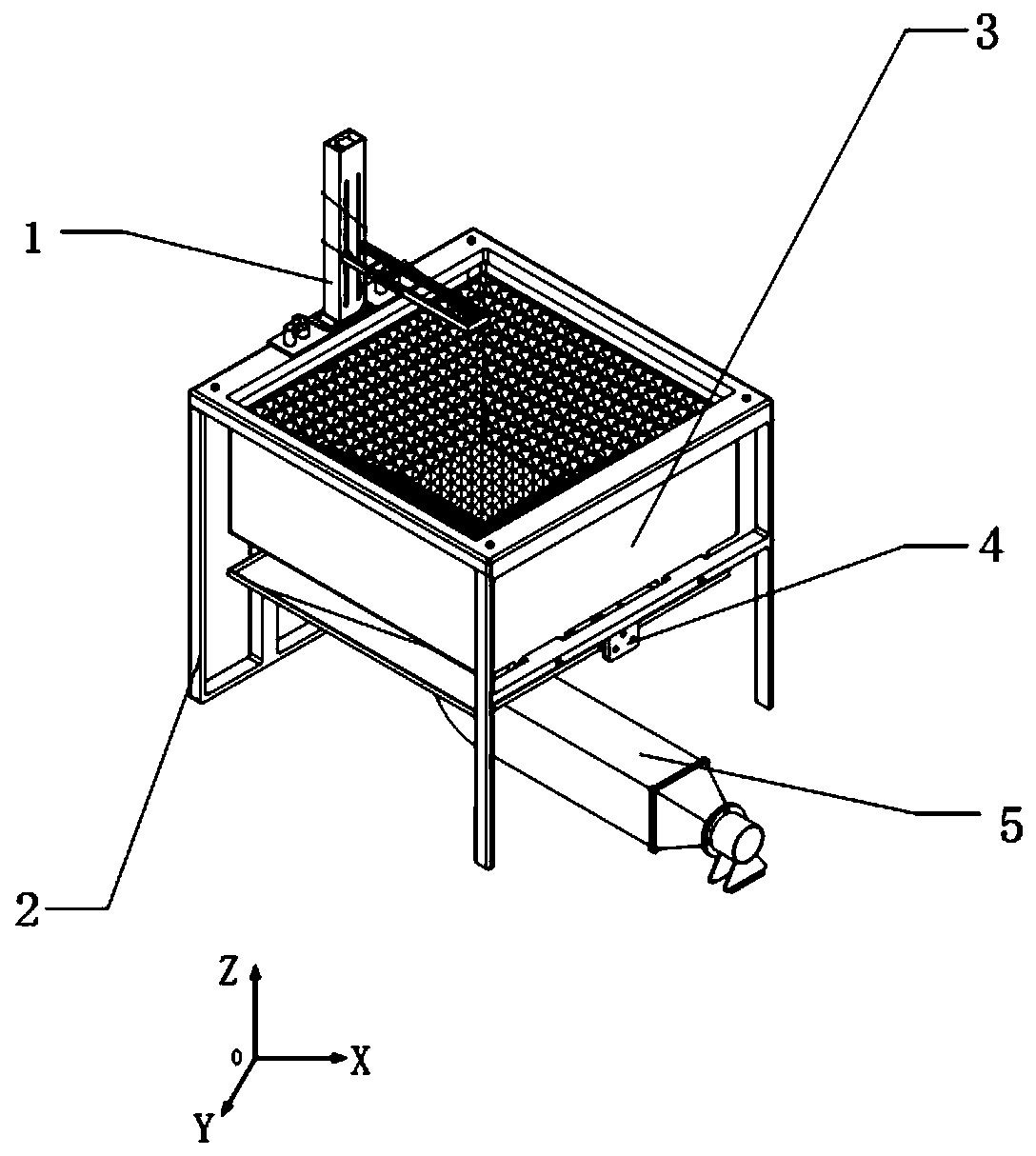

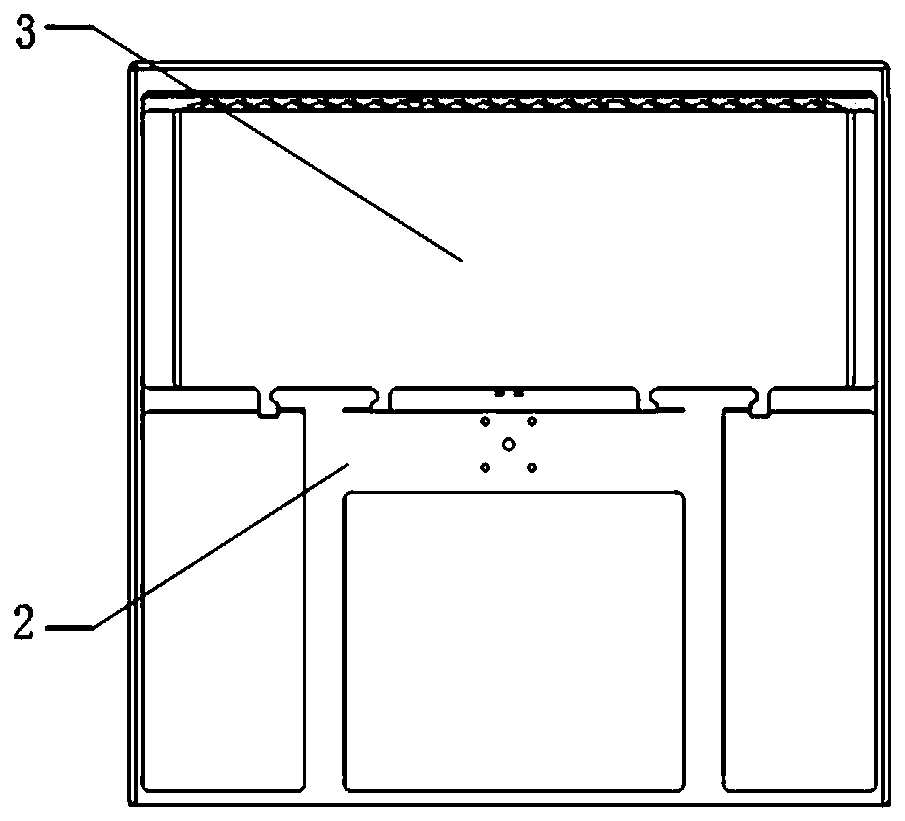

[0016] Such as figure 1 As shown, the present invention is made of stainless steel plate, the size is 1100mm in length, 1100mm in width, and 1000mm in height. From top to bottom, it consists of nozzle adjustment table 1, test bench frame 2, collection table 3, ball screw slide table 4, and ventilation The device 5 is composed of; the nozzle adjustment table 1 is arranged on one side of the test bench frame 2, the collection table 3 is embedded in the frame of the test bench frame 2, and the ball screw slide table 4 is connected to the bracket 11 and the collection table through a slider 3 are connected, and the air exhaust device 5 is located below the collection table 3.

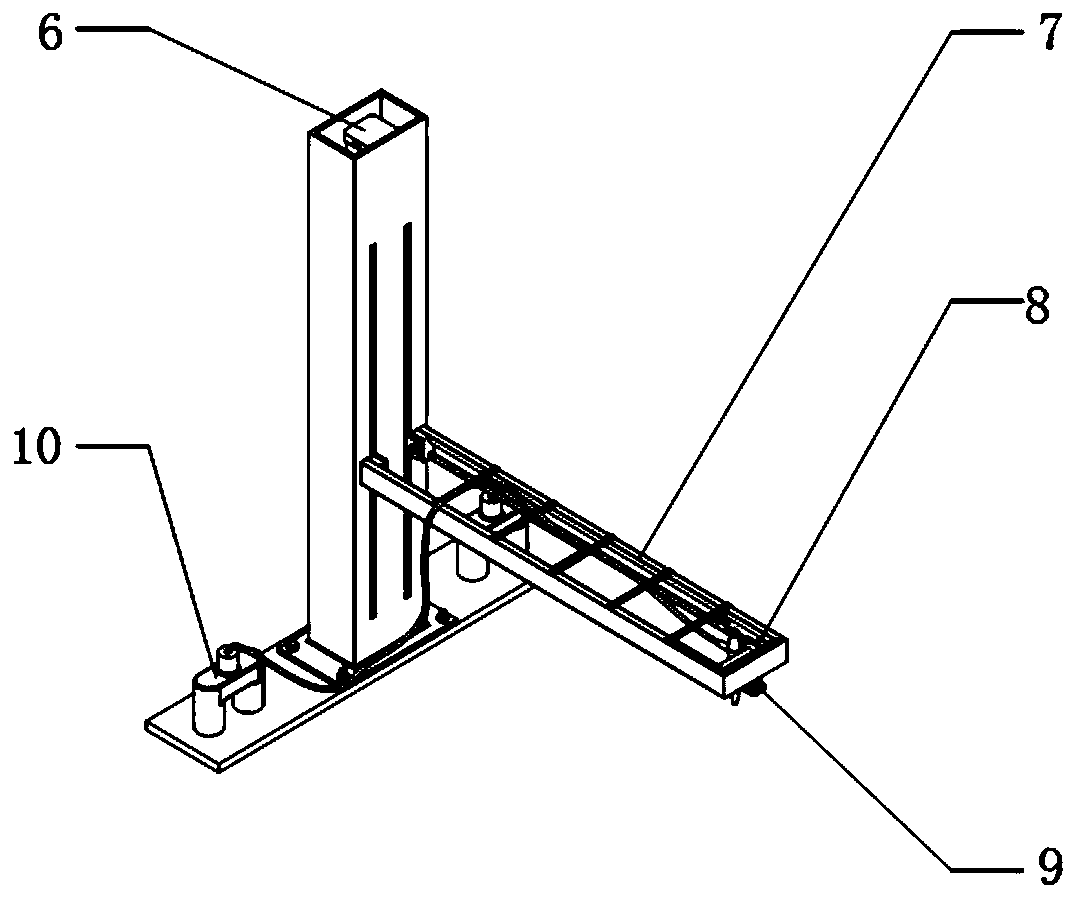

[0017] Such as figure 2 As shown, the nozzle adjustment table 1 is composed of a nozzle lifting device 6, a cantilever beam 7, a nozzle roller 8, a nozzle connecting frame 9, and a propellant tee 10; a ball screw is provided in the nozzle lifting device 6 to connect with the cantilever beam 7, and the noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com