Frequency agile resonant cavity antenna

A resonant cavity antenna and frequency agility technology, applied in the field of resonant cavity antennas, can solve the problems of drastic gain changes, low efficiency, and large size of resonant cavity antennas, and achieve the effects of low profile, simple feeding, and stable radiation gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

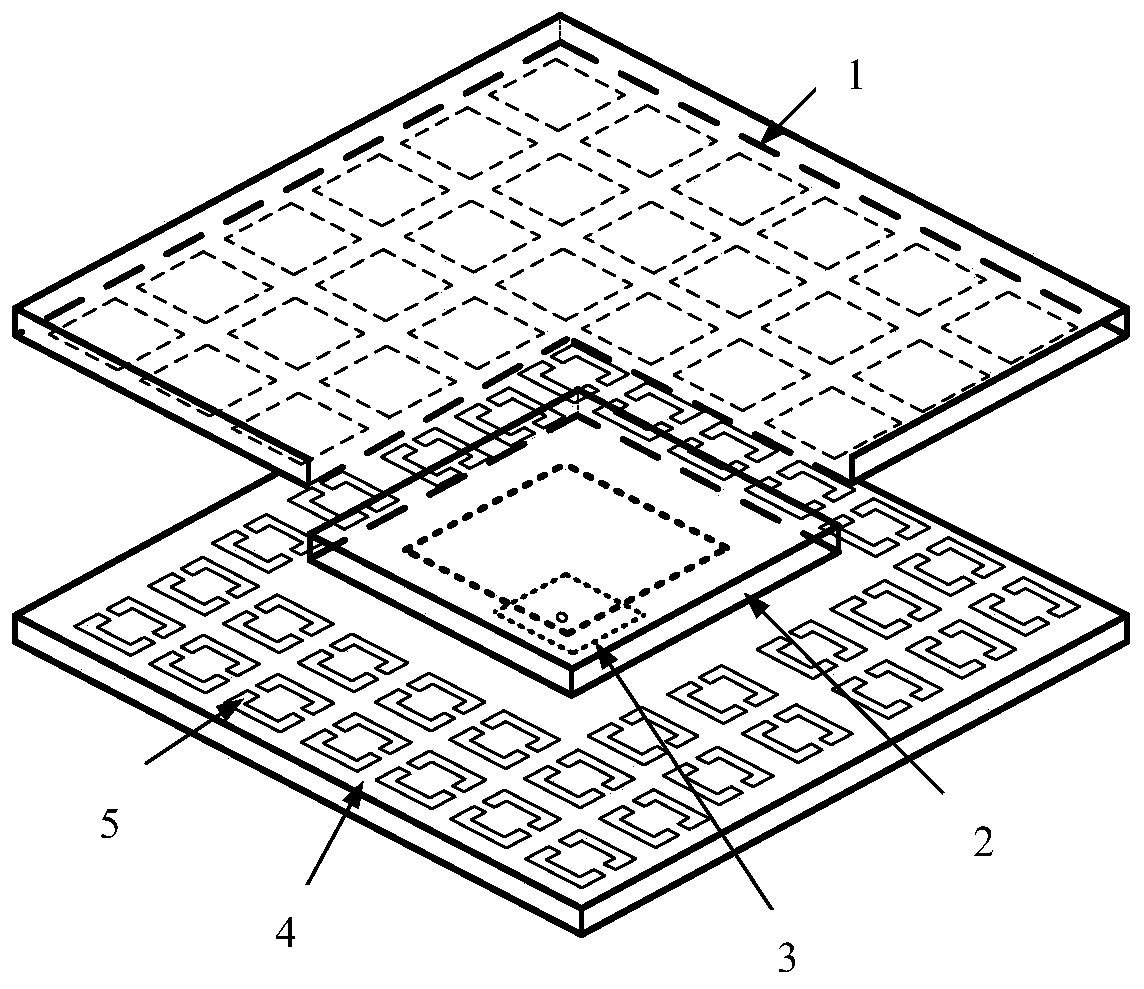

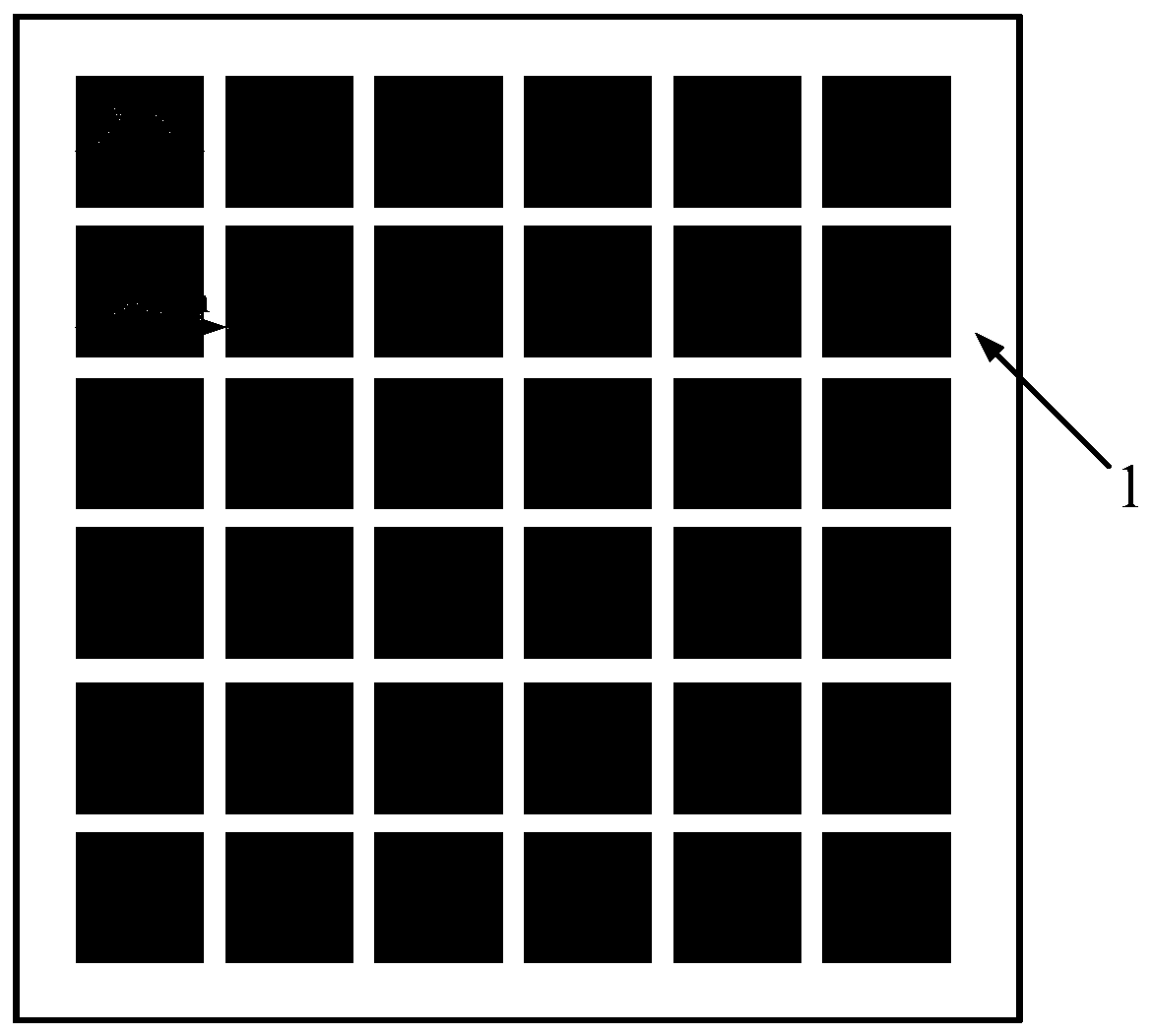

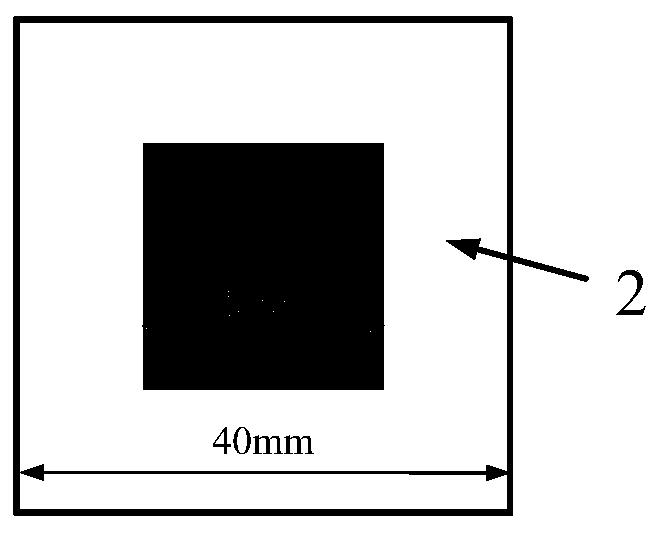

[0040] Using Rogers4003C plate with a thickness of 1.524mm and a relative dielectric constant of 3.55 as the reflective coating 1, the size is 140mm*140mm, and 6*6 square metal patch units with a side length of 19mm are printed under the dielectric plate; the thickness is 0.508 The Rogers5880 plate with a relative dielectric constant of 2.2 is used as the supporting plate of the parasitic feed, and a square parasitic patch with a side length of 16mm is printed under the dielectric plate; the Rogers4003C plate with a thickness of 1.524mm is used as the main feed and the high-impedance surface. The support plate is 140mm*140mm in size. A square patch with a side length of 13.2mm is printed in the center of the upper layer of the dielectric board, 7*7 high-impedance units and the feeder lines of the units. The lower layer of the dielectric board is a metal floor; the high-impedance unit is a metal A ring structure, slotting in the middle of the metal ring structure and loading two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com