N, N'-diisopropyl thiourea synthesis method

A technology of diisopropylthiourea and synthesis method, which is applied in the field of N, can solve problems such as expensive reagents, hidden dangers, and safety of poisonous gas leakage, and achieve the effects of simple feeding and post-processing, mild reaction conditions, and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

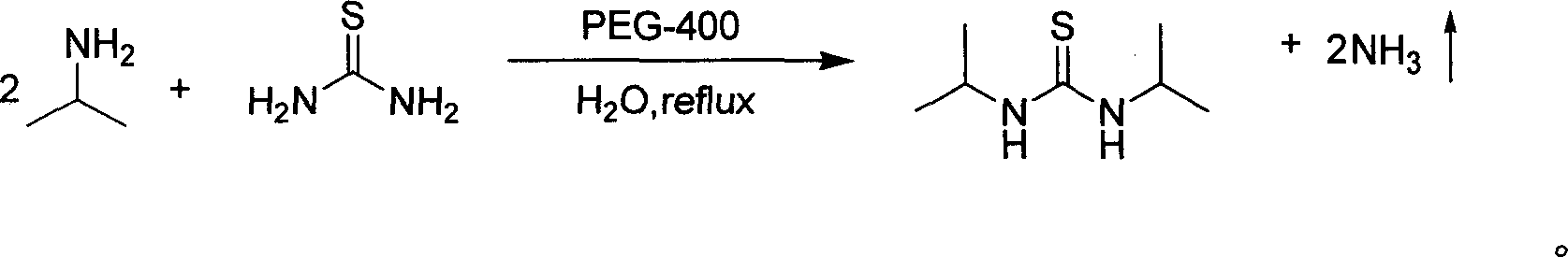

[0014] N, the concrete reaction steps of the synthetic method of N '-diisopropylthiourea are as follows:

[0015] With water as the reaction solvent and PEG-400 as the catalyst, thiourea and diisopropylamine were refluxed at normal pressure for 20 to 36 hours, and then filtered and washed to obtain high-yield, high-purity N, N'-di Isopropylthiourea; reaction solvent and catalyst can be recycled. The molar equivalent ratio of thiourea and diisopropylamine is 0.4-0.6:1; the amount of catalyst PEG-400 is 2-10% molar equivalent of thiourea. The recommended reaction time is 24 to 30 hours; the recommended molar equivalent ratio of thiourea and diisopropylamine is 0.45 to 0.55:1, and the most preferred ratio is 0.5:1; the recommended dosage of catalyst PEG-400 is 2 to 7 times that of thiourea % molar equivalent, most preferably 4% molar equivalent.

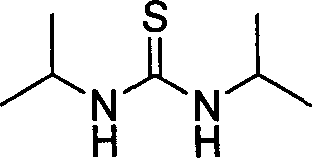

Embodiment 1

[0018] Mix 10 millimoles of thiourea, 20 millimoles of diisopropylamine and 0.4 millimoles of PEG-400 in 20 milliliters of water, heat and reflux under normal pressure for 26 hours, finish the reaction, cool down, precipitate the product, filter (recover the filtrate), Washed with water and dried to obtain 1.4 g of N,N'-diisopropylthiourea with a yield of 78% and a melting point of 142-145°C.

Embodiment 2

[0020] 9 millimoles of thiourea and 20 millimoles of diisopropylamine were mixed in the filtrate that was recovered in Example 1, heated and refluxed at normal pressure for 36 hours, and the reaction was terminated, cooled, and the product was separated out, filtered (recovered from the filtrate), water After washing and drying, 1.42 g of N,N'-diisopropylthiourea was obtained, with a yield of 80% and a melting point of 143-145°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com