Optical module

An optical module, input optical fiber technology, applied in the field of optical communication, can solve the problems of increasing the difficulty and complexity of the production process, limited placement position, complex production process, etc., to improve the output optical power and receiving sensitivity, flexible placement position, The effect of simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

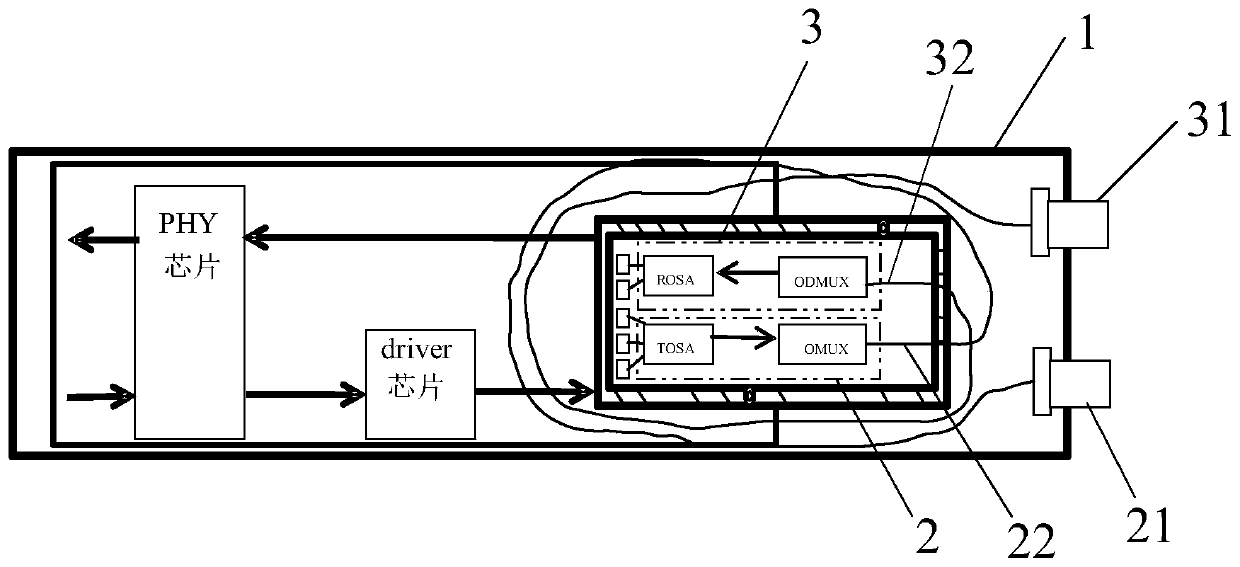

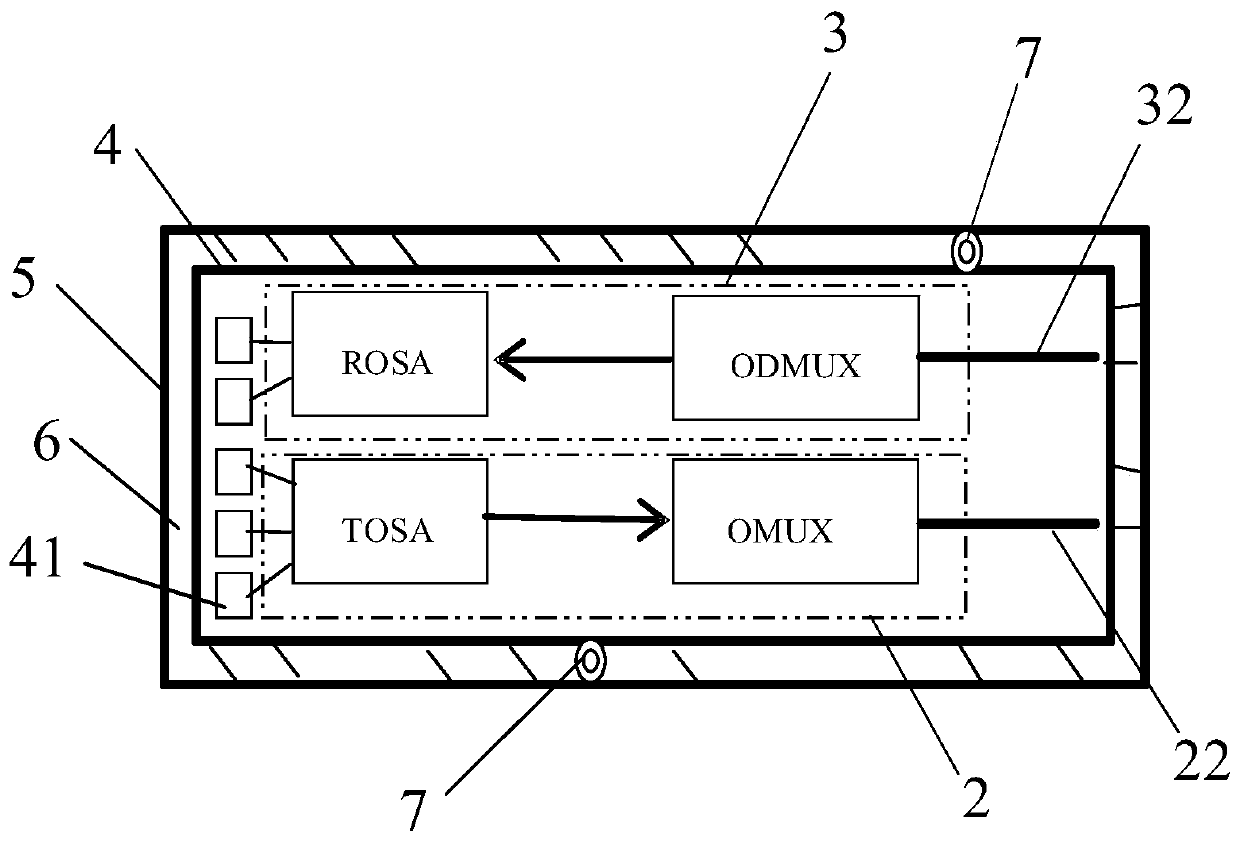

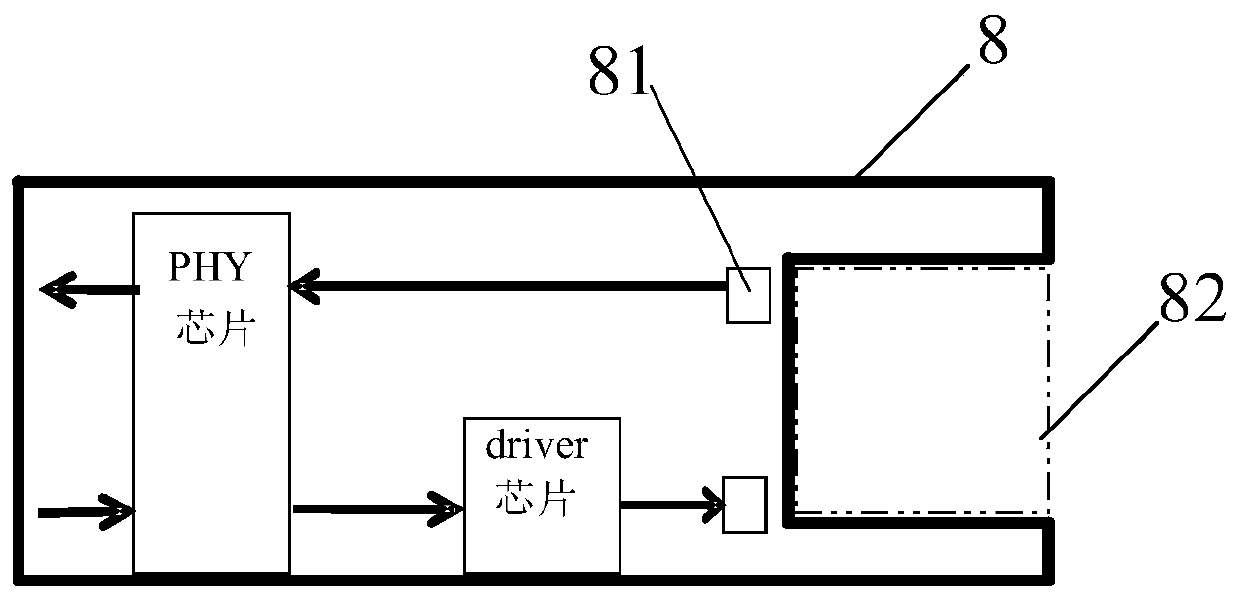

[0034] refer to figure 1 , this embodiment provides an optical module, the optical module includes: a package 1, a light emitting component 2, a light receiving component 3, a light transmitting interface 21 and a light receiving interface 31, the light transmitting component 2 and the light receiving The assembly 3 is arranged in the casing 1, the light emitting interface 21 and the light receiving interface 31 are arranged on the casing 1, the output optical fiber 22 is arranged on the side of the light emitting assembly 2, and the light receiving interface An input optical fiber 32 is provided on the module 3 side.

[0035] Wherein, the output optical fiber 22 is wound around the light emitting assembly 2 and the light receiving assembly 3, and then connected to the light emitting interface 21; the input optical fiber 32 surrounds the light emitting assembly 2 and the light receiving assembly 3. After the receiving component 3 is wound, it is connected with the light recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com