Constrained rolling forming method for large thin-walled outer T-shaped annular members

A ring-shaped component and thin-walled technology, applied in the field of large-scale ring forming and manufacturing, to achieve high material utilization, low energy consumption, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

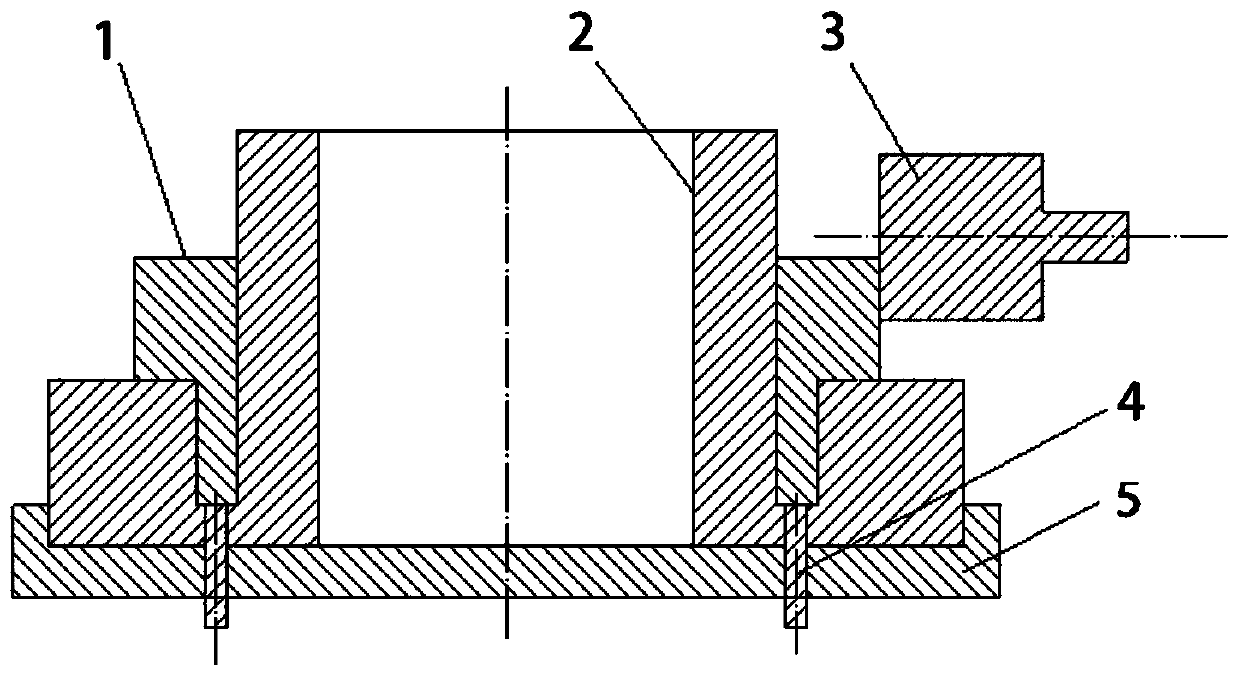

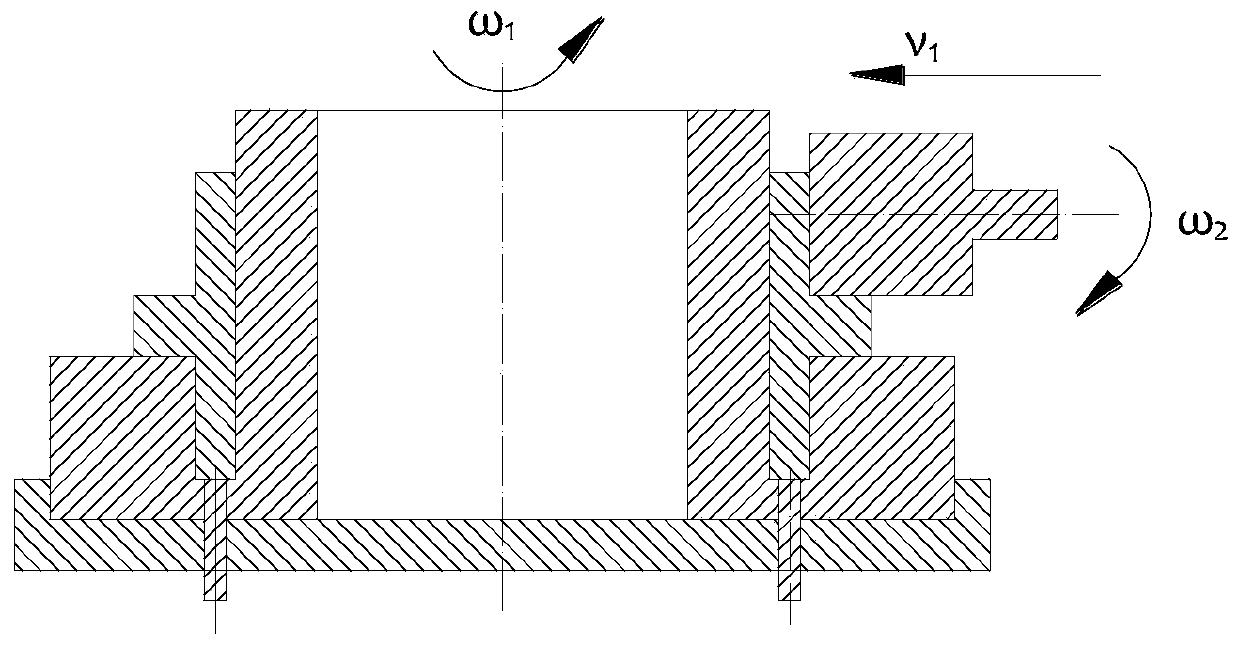

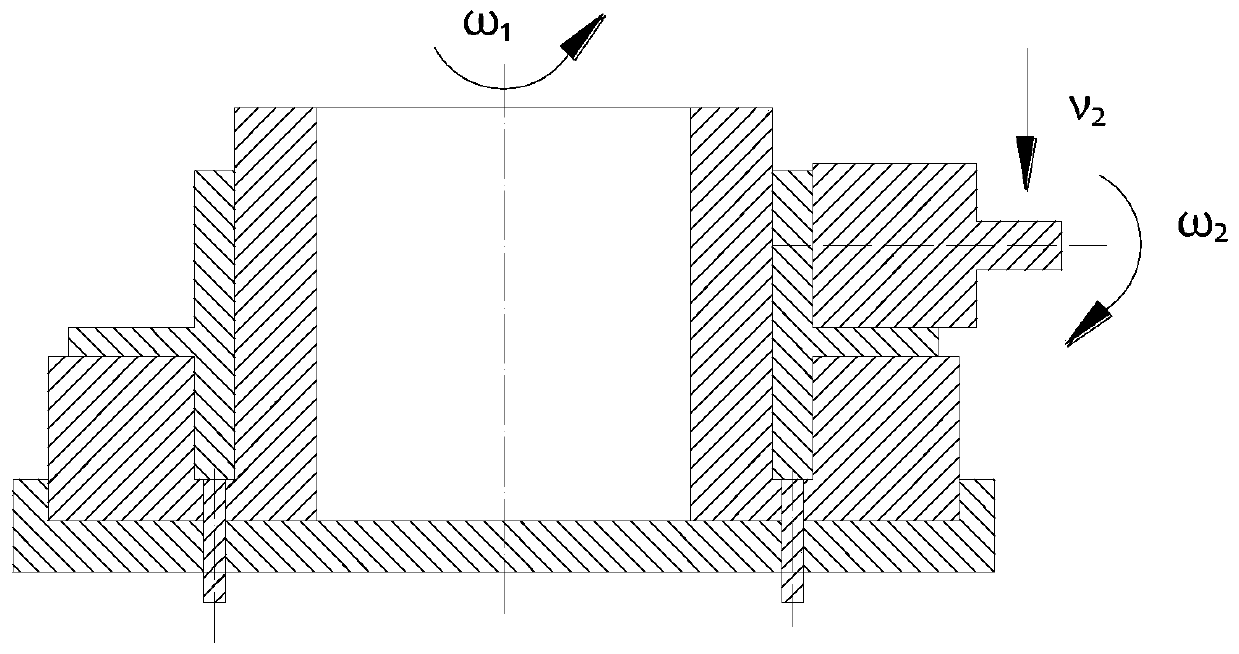

[0033] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0034] The constrained rolling forming method of large thin-walled outer T-shaped annular member of the present invention comprises the following steps:

[0035] S1. Obtain a trapezoidal prefabricated ring blank 1 by conventional rolling, casting and other methods. Its inner diameter D 1 and target ring inner diameter d 1 Same, its small end ring is just placed in the groove of the constraining die 2, and the diameter of the large end face is D 3 Determined by the radial roll ratio λ.

[0036] D. 1 = d 1 (1)

[0037] D. 2 = d 2 (2)

[0038] D. 3 =λ*D 1 (3)

[0039] Axial height H of big end ring 2 for:

[0040]

[0041] Among them, d 1 , d 2 Respectively, the inner and outer diameters of the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com