Spare tire cover plate and production method thereof

A spare tire cover and base plate technology, which can be applied to the layout of spare tires, other household appliances, household components, etc., can solve the problems of affecting appearance and exposure, and achieve the effects of improving appearance, expanding connection methods, and prolonging the folding life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

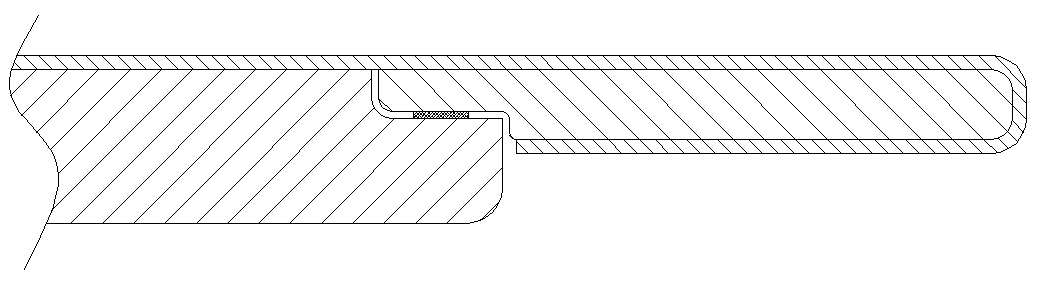

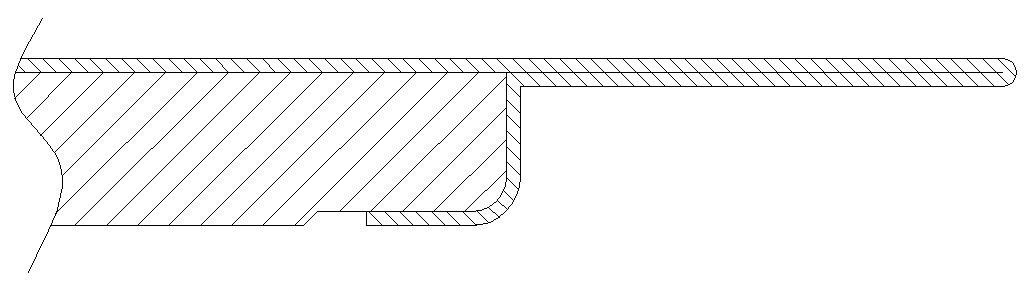

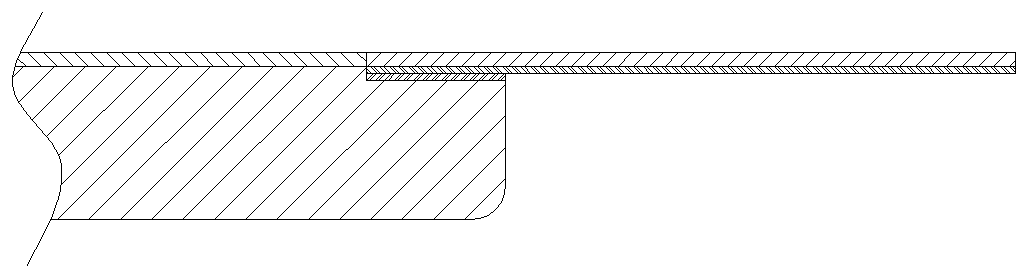

[0040] Such as image 3 , 4 , 5, and 7, the spare tire cover is divided into a fixed part and an overlapping part. The substrate material of the fixing part is PHC, and the material of the overlapping part is thermoplastic material. A thermoplastic embedded part is provided at the front end of the base plate of the fixed part, and the thermoplastic embedded part is not covered when covering the fabric. The overlapping part and the thermoplastic embedded part on the base plate of the fixed part are connected together by welding.

[0041]The embedded part on the base plate of the fixed part is a thermoplastic sheet, more specifically, it can be a PP sheet, but the surface energy of the PP sheet itself is too low, and it is not easy to be compatible with the polyurethane foam of the PHC cover, so it needs to be placed on the surface (at least the lower surface) corona or plasma treatment in advance. Of course, you can also apply a primer on the surface of the PP sheet, but th...

Embodiment 2

[0050] like Figure 4 , 5 , 7, a groove is provided at the rear boundary of the embedded part on the PHC substrate of the fixed part. This kind of PHC substrate with grooves is also very simple to produce, as long as a convex edge is set on the mold and the draft angle is considered. Moreover, this convex rib can also serve as a limit function when placing PP embedded parts, so that the position of thermoplastic embedded parts is more consistent, and the subsequent fabric compounding and lap joint assembly operations will be more convenient.

[0051] The advantage of this groove is that when attaching the fabric to the PHC substrate, the edge of the fabric can be stuffed into the groove, so as to avoid the exposure of broken stubble and affect the appearance. Figure 4 shown. Of course, the groove can also be made wider, and the broken stubble of the PP sheet can also be stuffed into the groove. Figure 7 shown. However, the PP sheet is very hard, and the edge treatment n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com