Electrolytic flotation device for wastewater treatment

An electrolytic air flotation and wastewater treatment technology, which is applied in water/sewage treatment equipment, water/sewage treatment, flotation water/sewage treatment, etc., can solve the problem of hydrogen bubble activity and limited range of action, reduce the amount of bubbles around the electrode, Reduce the practicability of the electrolytic air flotation device to achieve the effect of preventing signal overflow, increasing the range of activities, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

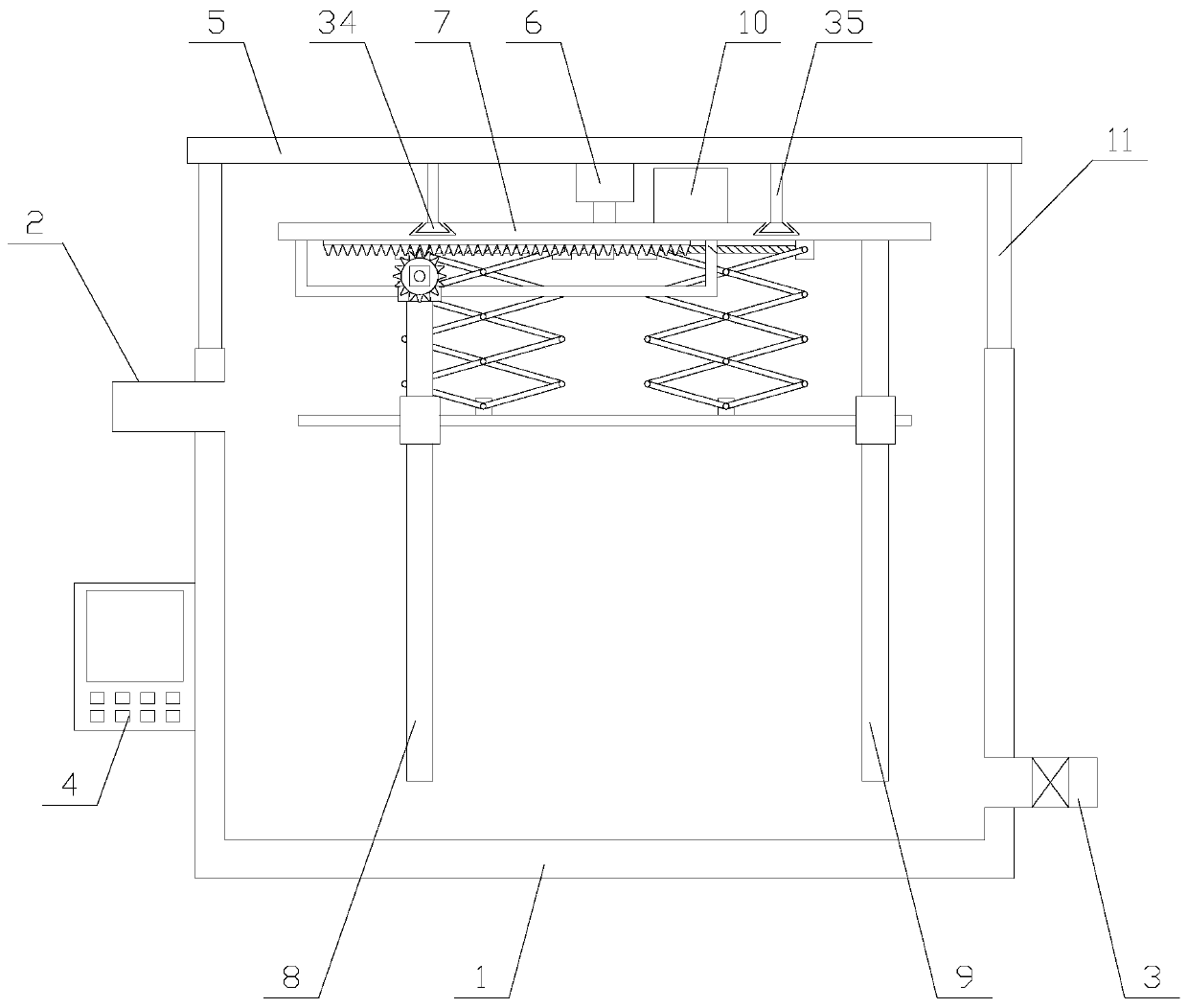

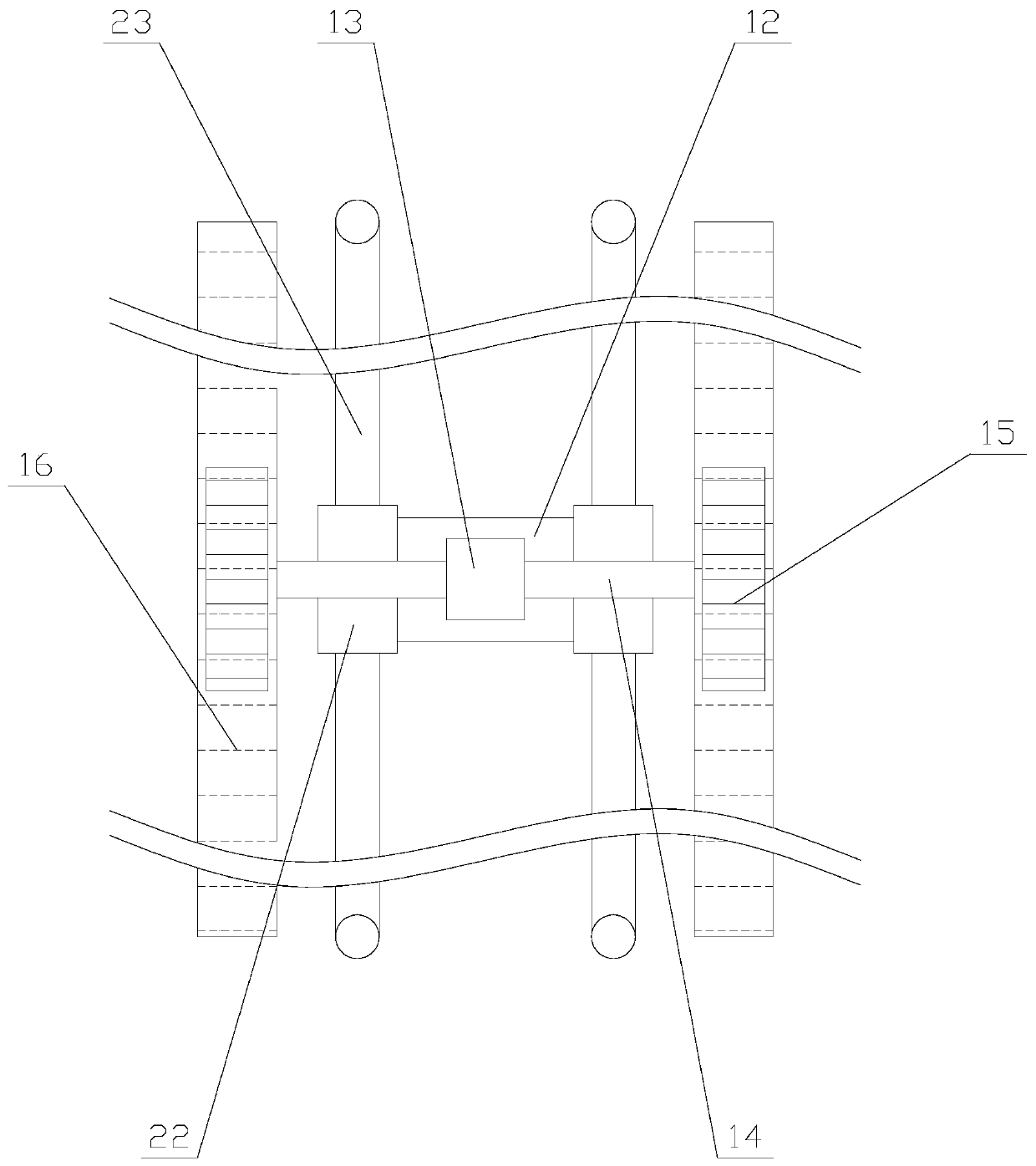

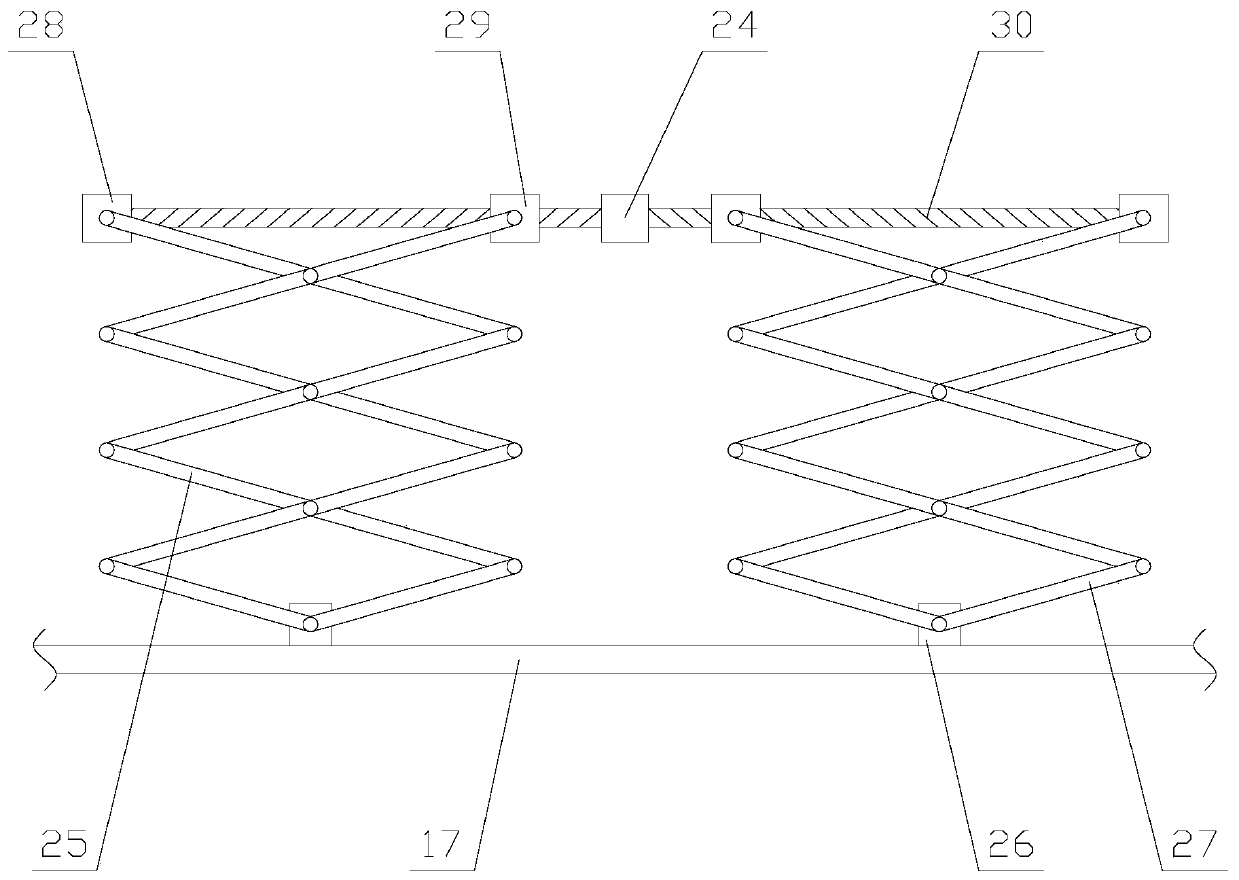

[0028] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0029] Such asfigure 1 As shown, an electrolytic air flotation device for wastewater treatment includes a pool 1, a water inlet pipe 2, a drain pipe 3, a controller 4, a top cover 5, a first motor 6, a disk 7, a cathode 8, an anode 9, A moving mechanism, a cleaning mechanism, a storage battery 10 and two support rods 11, the water inlet pipe 2 and the drain pipe 3 are respectively arranged on both sides of the pool 1, and the water inlet pipe 2 and the drain pipe 3 are all communicated with the pool 1. The drain pipe 3 is provided with a valve, the controller 4 is fixed on the pool 1, the controller 4 is provided with a PLC, and the two support rods 11 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com