Inorganic ceramic energy storage self-luminous material, preparation method and application thereof, self-luminous ceramic particles and self-luminous ceramic tile

A technology of self-luminous materials and inorganic ceramics, applied in the field of materials, can solve the problems of inability to meet the requirements of users' luminous brightness, reduce the luminous brightness of self-luminous materials, destroy the luminous performance of luminescent materials, etc., and achieve acid and alkali resistance and fire resistance. Strong, high hardness, the effect of improving luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

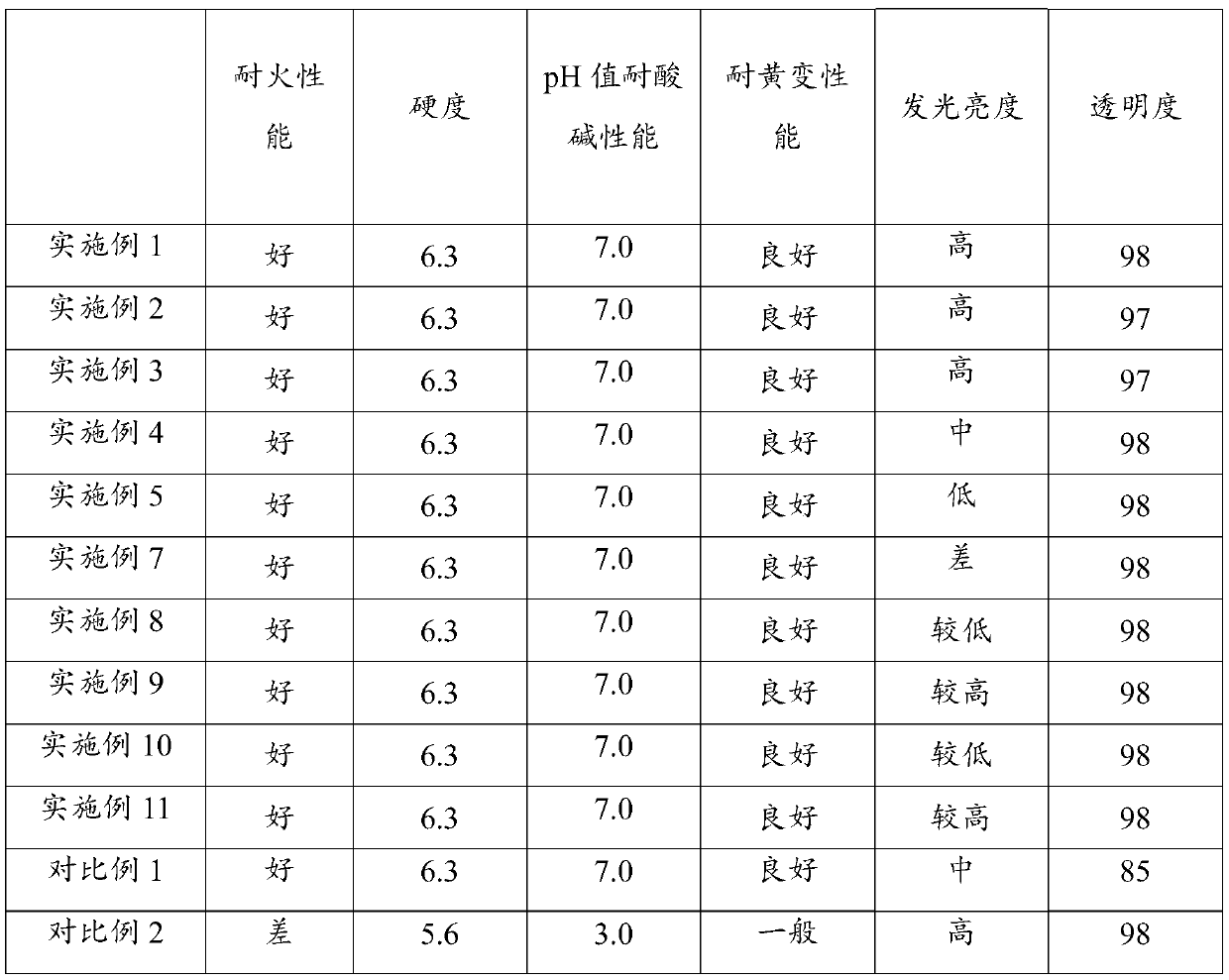

Examples

preparation example Construction

[0044] In another aspect of the present invention, the present invention provides a method for preparing the aforementioned inorganic ceramic energy-storage self-luminous material, the preparation method comprising: ℃, 700°C or 800°C, etc.) to bake the mixture of raw materials to obtain the inorganic ceramic energy storage self-luminous material; preferably, bake the mixture of low-melting glass powder and luminescent material at 400-800°C , to obtain the inorganic ceramic energy storage self-luminous material. Therefore, the operation is simple and convenient, easy to implement, low energy consumption, less waste of resources, and low production cost.

[0045] In some embodiments of the present invention, the mixture of the low-melting glass powder and the luminescent material is prepared by the following method:

[0046] Stir the mixture of the low melting point glass powder and the luminescent material, the stirring speed is 500-800r / min (for example, 500r / min, 600r / min, 7...

Embodiment 1

[0069] Inorganic ceramic energy storage self-luminous materials include the following mass fractions of raw materials:

[0070] Low melting point glass powder 62.5wt%, luminescent material 37.5wt%;

[0071] The luminescent material is rare earth aluminate long afterglow powder, the model of low melting point glass powder is GT40, and the melting point of low melting point glass powder is 400°C.

Embodiment 2

[0073] The composition of the inorganic ceramic energy-storage self-luminous material is the same as that in Example 1, except that the model of the low-melting glass powder is G107, and the melting point of the low-melting glass powder is 600°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com