A kind of preparation method of modified silicon phenolic resin adhesive

A silicon phenolic resin and adhesive technology, which is applied in the directions of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of difficult control of the reaction process, product application restrictions, complex preparation process, etc. To achieve the effect of simple steps, improved comprehensive performance, and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

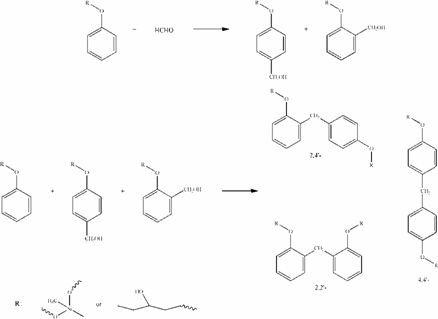

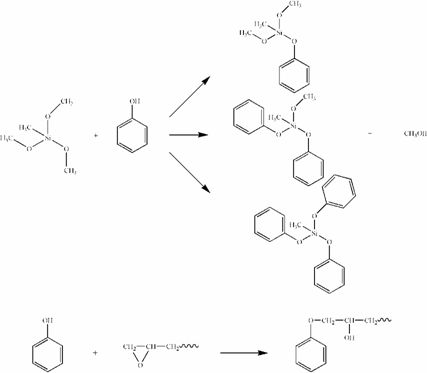

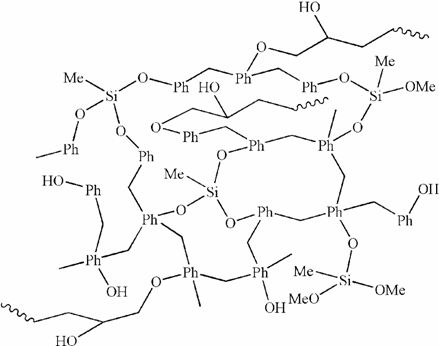

Method used

Image

Examples

Embodiment 1

[0027] Add 9.41 g of nylon, 41.27 g of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane, 94.11 g of phenol and 1.41 g of phosphoric acid into the reactor, stir evenly, and slowly heat up. React at 160°C to generate intermediates containing amide groups or silicon atoms; then slowly lower the temperature, add 26.13 g of paraformaldehyde, and further react with intermediates containing amide groups or silicon atoms at a temperature of 85°C to prepare A modified silicone phenolic resin adhesive based on blocked phenolic hydroxyl groups.

Embodiment 2

[0029] Add 15.56 g of epoxy resin, 116.20 g of methyltrimethoxysilane, 228.29 g of bisphenol A and 3.44 g of p-toluenesulfonic acid into the reaction kettle, stir evenly, slowly raise the temperature, and react at 165 ° C to form or intermediates of silicon atoms; then slowly lower the temperature, add 70.61 g of formaldehyde solution, and further react with intermediates containing epoxy groups or silicon atoms at a temperature of 90 ° C to prepare a modified silicon based on blocking phenolic hydroxyl groups Phenolic resin adhesive.

Embodiment 3

[0031] Add 36.17 g of bismaleimide, 68.11 g of methyltrimethoxysilane, 94.11 g of phenol and 1.88 g of methanesulfonic acid into the reaction kettle, stir evenly, slowly raise the temperature, and react at 158 ° C to form a group or silicon atom intermediate; then slowly lower the temperature, add 24.04 g of paraformaldehyde, through its further reaction with the intermediate containing imide ring group or silicon atom at a temperature of 85 ℃, to prepare a blockade-based Phenolic hydroxyl modified silicone phenolic resin adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com