Cigarette flavoring uniformity detection method based on additional marker

A detection method and marker technology, which can be applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of uniformity evaluation interference, insufficient to improve the uniformity of the cigarette flavoring process, etc., and achieve the effects of stable physical and chemical properties and easy extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] According to the selection principles of external markers: a) External markers do not exist in cigarette essence or shredded tobacco, nor will they be introduced during the production process. b) The physical and chemical properties of the added markers are stable, easy to be extracted and analyzed qualitatively and quantitatively. c) The structure and properties of the external markers are similar to the various characteristic aroma components in the cigarette flavor, and do not affect the aroma style of the cigarette.

[0090] Since there are many types of ester compounds in tobacco flavors and they play a key role in the quality of aroma, while the boiling point distribution of phenylglycolic acid esters is uniform, and their chemical structures and properties are similar to those of various ester compounds in flavors. Added and not present in the tobacco background, it is suitable as an external marker for evaluating the uniformity of flavoring.

[0091] Phenylglyc...

Embodiment 2

[0101] During the determination, accurately weigh 0.5000g (accurate to 0.0001g) of each of the 5 mandelic acid ester standards and place them in a 50mL volumetric flask, dissolve them with ethanol and constant volume to obtain a primary mixture with a mass concentration of 10000μg / mL Standard stock solution, and then take 0.5mL primary stock solution and dilute it to a 50mL volumetric flask to obtain a secondary mixed standard stock solution with a mass concentration of 100μg / mL, and store it in a 4°C refrigerator. Accurately pipette 0.05, 0.25, 0.50, 2.50, 5.00mL of the secondary mixed standard stock solution into a 50mL volumetric flask, add 0.5mL of benzyl acetate internal standard solution (100μg / mL), and dilute with ethanol to obtain the respective concentration A series of standard working solutions of 0.10, 0.50, 1.00, 5.00, 10.00 μg / mL.

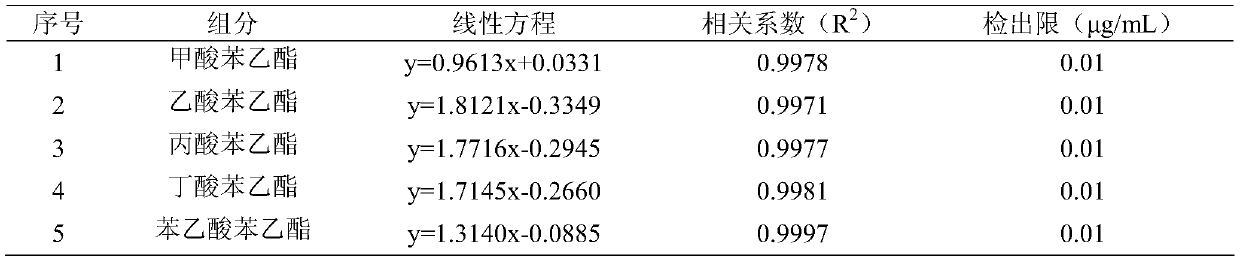

[0102] A series of standard working solutions with different concentrations were analyzed by GC-MS / MS to obtain the linearity of the...

Embodiment 3

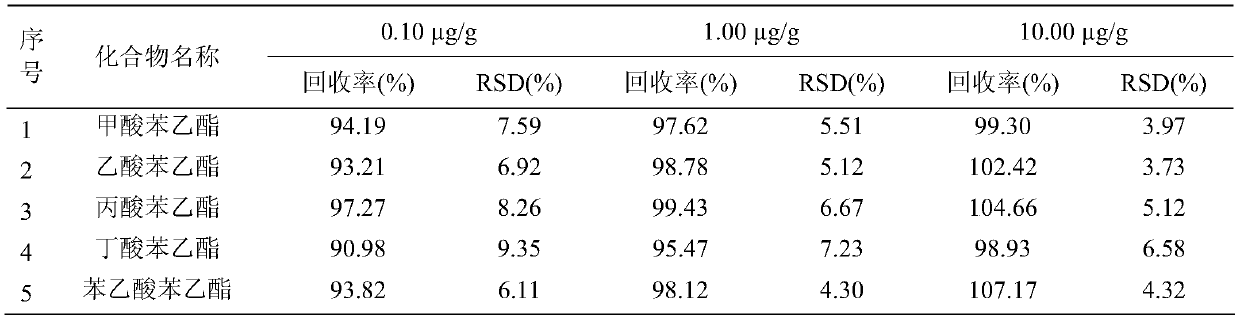

[0106] According to the method of flavoring and sampling in Example 1, select the same batch of flavored cut tobacco samples, weigh 5 parts in parallel, and quantitatively add mandelic acid ester standard solutions at three concentration levels of low, medium and high respectively to measure the concentration before and after adding the standard. The recovery rate of each mandelic acid ester was calculated by the average value of the determined content. The recoveries of the five mandelic acid esters at each addition level were all between 90.98% and 107.17%, which indicated that the recoveries of this method were better. The relative standard deviations (RSDs) of the 5 mandelic acid esters are all below 10%, indicating that the method has good reproducibility. The results are shown in Table 2.

[0107] Table 2 Recovery and repeatability evaluation of 5 kinds of mandelic acid esters under different addition levels (n=5)

[0108]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionization energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com