Making method of color filter and color filter

A technology for color filters and manufacturing methods, which are applied in the fields of filters, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of contamination of adjacent film layers or pixels, floating color, and dye precipitation, etc. Guarantee the display effect and avoid the effect of diffusion pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

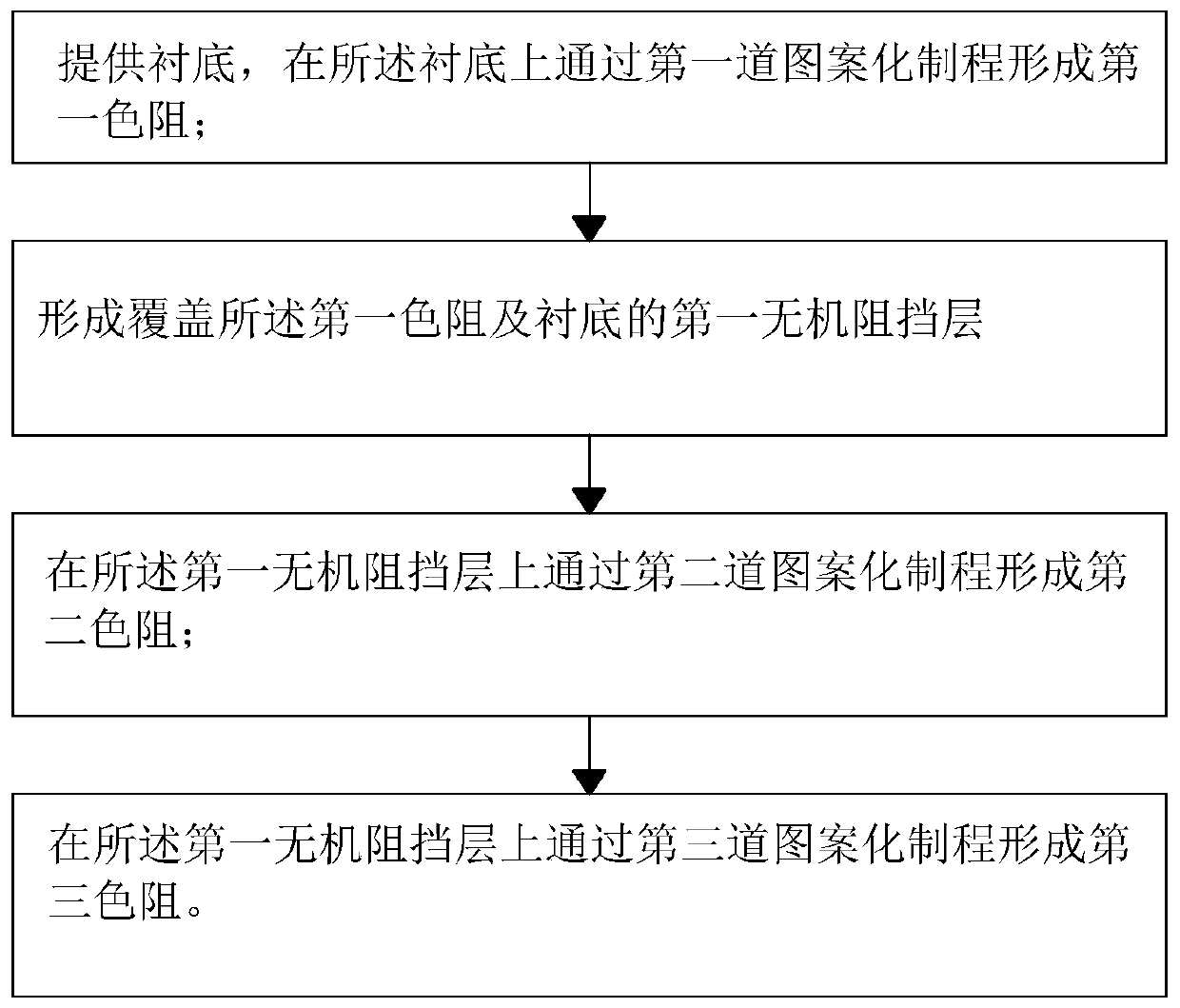

Method used

Image

Examples

no. 1 example

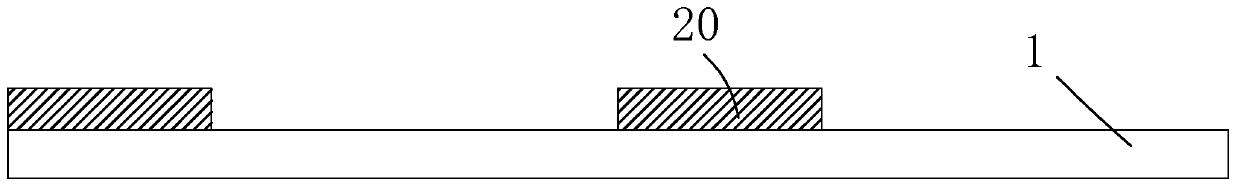

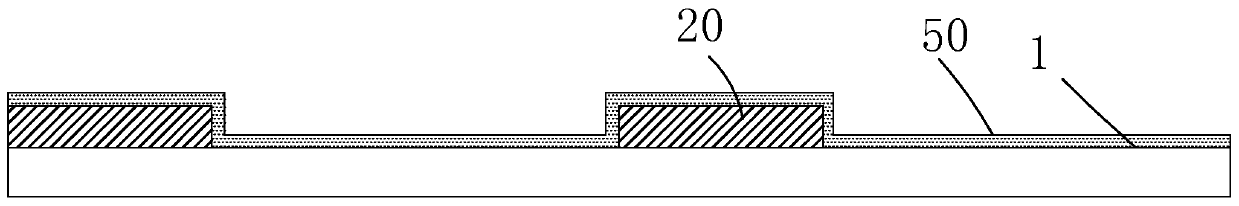

[0072] see Figure 5 , corresponding to the first embodiment of the present invention, the present invention is also a color filter, including a substrate 1, a color resist layer 2 and an inorganic barrier layer 3;

[0073] The color-resist layer 2 includes a first color-resist 20 , a second color-resist 30 , and a third color-resist 40 arranged repeatedly along the surface of the substrate 1 ;

[0074] The inorganic barrier layer 3 includes a first inorganic barrier layer 50 covering the first color resistance 20, and the first inorganic barrier layer 50 connects the first color resistance 20 with the second color resistance 30 and the third color resistance. 40 apart.

[0075] Wherein, the material of the color-resisting layer 2 is a mixed color-resisting material including dyes and pigments, and the colors of the first color-resisting 20, the second color-resisting 30, and the third color-resisting 40 are different. Due to the small molecule properties of dyes, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com