Drill bit test automatic measurement and control circuit

A drill test and circuit technology, applied in program control, computer control, general control system, etc., can solve the problems of cumbersome procedures, time-consuming, inaccurate results, etc., and achieve strong anti-interference ability, consistent working conditions, and stable rotation speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

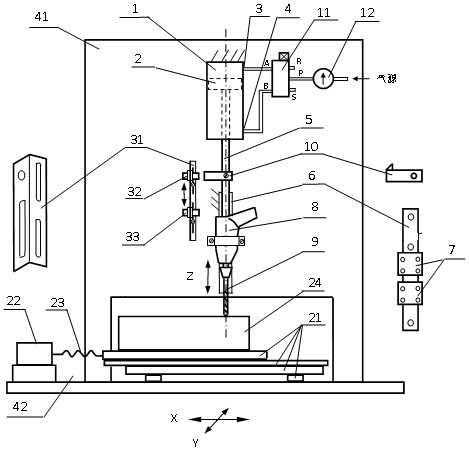

[0018] like figure 1 As shown, the drill test bench includes an installation frame, a bearing mechanism and a drilling mechanism, and the bearing mechanism and the drilling mechanism are installed on the installation frame to form a test platform as a whole; the installation frame is composed of a wall plate 41 and a bottom plate vertically connected to it. 42; the bearing mechanism includes a cross slide 21, an X-axis stepper motor 22, an X-axis screw 23, a cross slide 21 is installed on the bottom plate 42, and the cross slide 21 includes guide rails in the X-axis and Y-axis directions respectively. and the pallet, the X-axis stepper motor 22 (model 86BYG250D) is connected to the X-axis pallet of the cross slide 21 through the X-axis screw 23 (specification M12×4), and the X-axis carriage of the cross slide 21 is connected by the X-axis stepper The feeding motor 22 is dragged by the X-axis screw 23 to move in the X-axis direction, the Y-axis stepping motor is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com