Production process of insect pest prevention waterproof power cable

A power cable and production process technology, which is applied in the production process field of pest-proof and waterproof power cables, can solve problems such as drainage difficulties, wire and cable fire accidents, and reduce service life, so as to save labor costs, ensure water-blocking effects, and avoid allergies The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

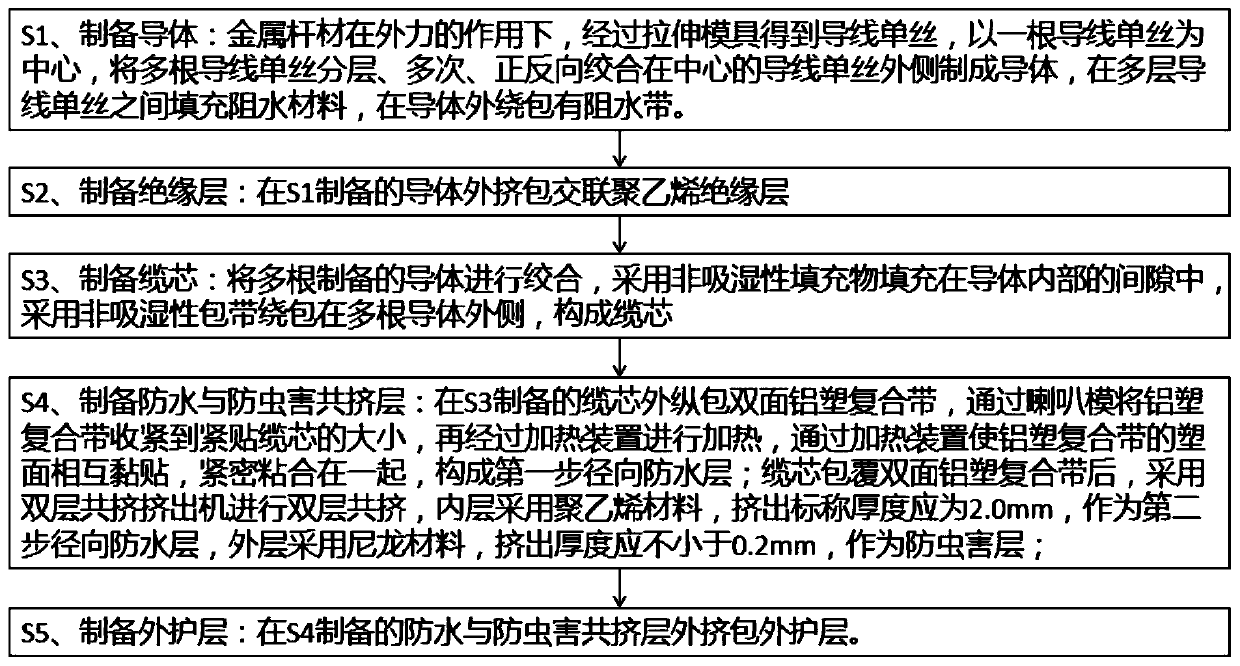

[0030] refer to figure 1 Shown, the manufacturing step of the production technology of insect-proof waterproof power cable of the present invention;

[0031] S1. Preparation of conductor: Under the action of external force, the metal rod is stretched through a stretching die to obtain a wire monofilament. With one wire monofilament as the center, multiple wire monofilaments are layered, multiple times, forward and reverse twisted together. The outside of the wire monofilament in the center is made into a conductor, and water-blocking materials are filled between the multi-layer wire monofilaments, and a water-blocking tape is wrapped around the conductor;

[0032] In this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com