Polymer lithium ion battery formation process capable of exhausting gas and supplementing liquid

A lithium-ion battery, polymer technology, applied in secondary batteries, electrochemical generators, secondary battery charging/discharging, etc., can solve the problem of insufficient electrolyte, ignoring the needs of battery exhaust and rehydration, and waste of aluminum plastic film. It can improve the safety performance and electrochemical performance, improve the electrochemical performance, and achieve the effect of capacity recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A polymer lithium-ion battery formation process capable of exhausting and replenishing liquid, the steps are as follows:

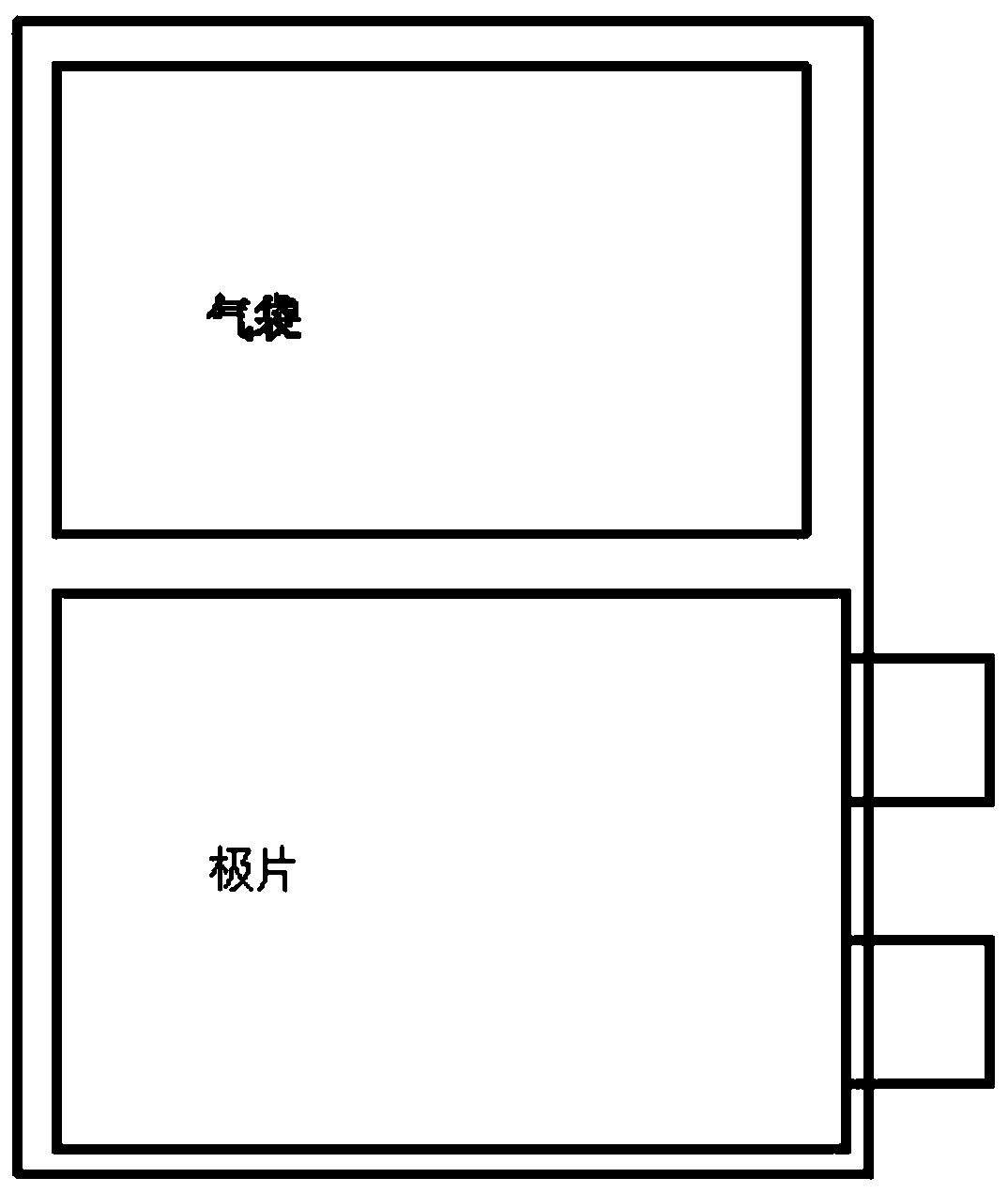

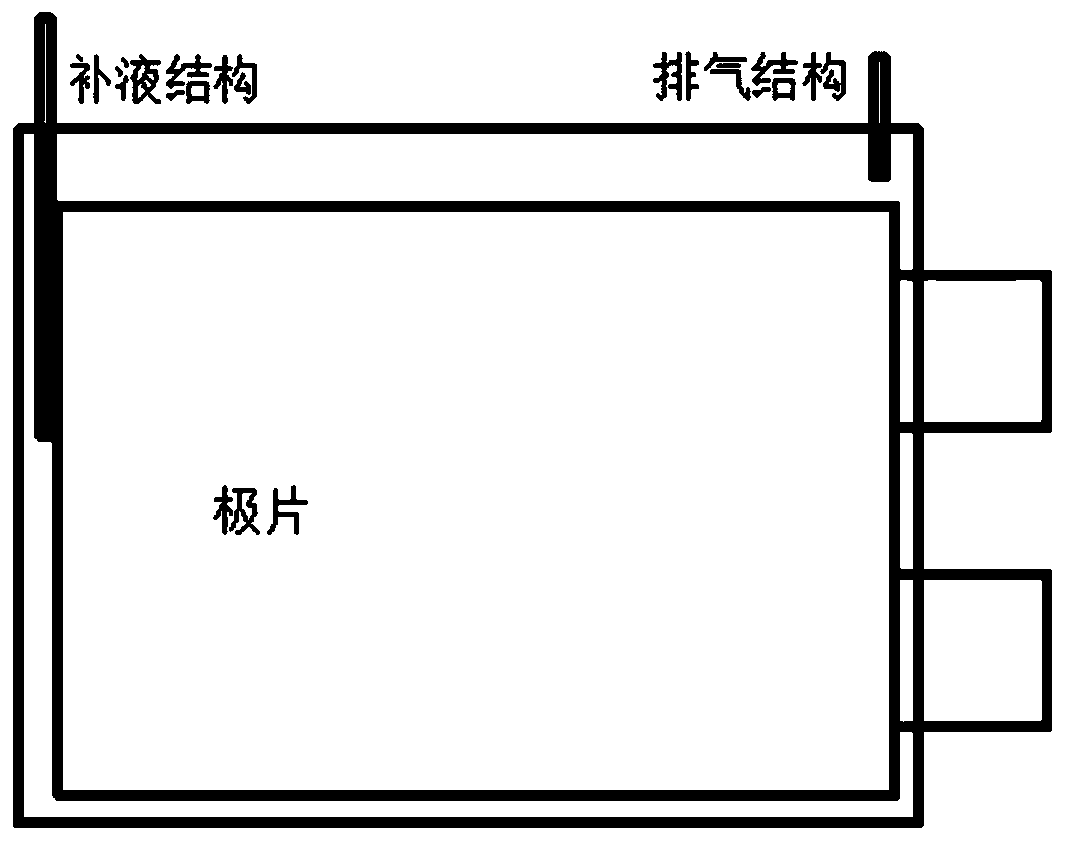

[0038] S1. Before the battery cell is packaged, insert the liquid replenishment pipeline into the battery cell along the bottom of the battery pole piece, and connect the exhaust pipeline along the top of the battery cell to the edge of the battery cell; there is no fixed limit on the diameter and length of the pipeline, and the battery The external dimensions are related, and the lithium battery pouch battery has no fixed external dimension requirements, and can be designed according to the requirements;

[0039] Process: a. Manually or equipment cuts the pipeline to the specified or calculated size; b. Manually or equipment inserts the pipeline into the specified position inside the cell along the aluminum-plastic film. The specified position: the liquid replenishment pipeline is the bottom of the pole piece Inner position; the exhaust pipe is nex...

Embodiment 2

[0051] A polymer lithium-ion battery formation process that can exhaust and replenish liquid, which is used for the preparation, packaging and formation of polymer lithium-ion cells; exhaust and replenish liquid when polymer lithium-ion cells are inflated; when the electrolyte volume is insufficient, the capacity of the cells and performance recovery; polymer lithium-ion battery cascade utilization and recycling process.

[0052] Proceed as follows:

[0053] (1) Before the cell is packaged, insert the liquid replenishment line into the cell along the bottom of the battery pole piece, connect the exhaust line to the edge of the cell along the top of the cell, and preset a special line for automatic exhaust and liquid replenishment. The pipeline is made of electrolyte corrosion-resistant material, and the diameter and length of the pipeline are related to the battery specifications;

[0054] (2) Use a liquid injection pump, after the first injection of 60% to 90% of the liquid,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com