Flexible circuit board hot-pressing device

A technology of flexible circuit boards and hot pressing equipment, which is applied in the directions of laminated printed circuit boards, printed circuits, and printed circuit manufacturing, etc., can solve the problems that the hot pressing head cannot be quickly, is not easy to cool down, and the temperature rises, so as to increase the heat dissipation effect. , uniform heat dissipation, the effect of increasing the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

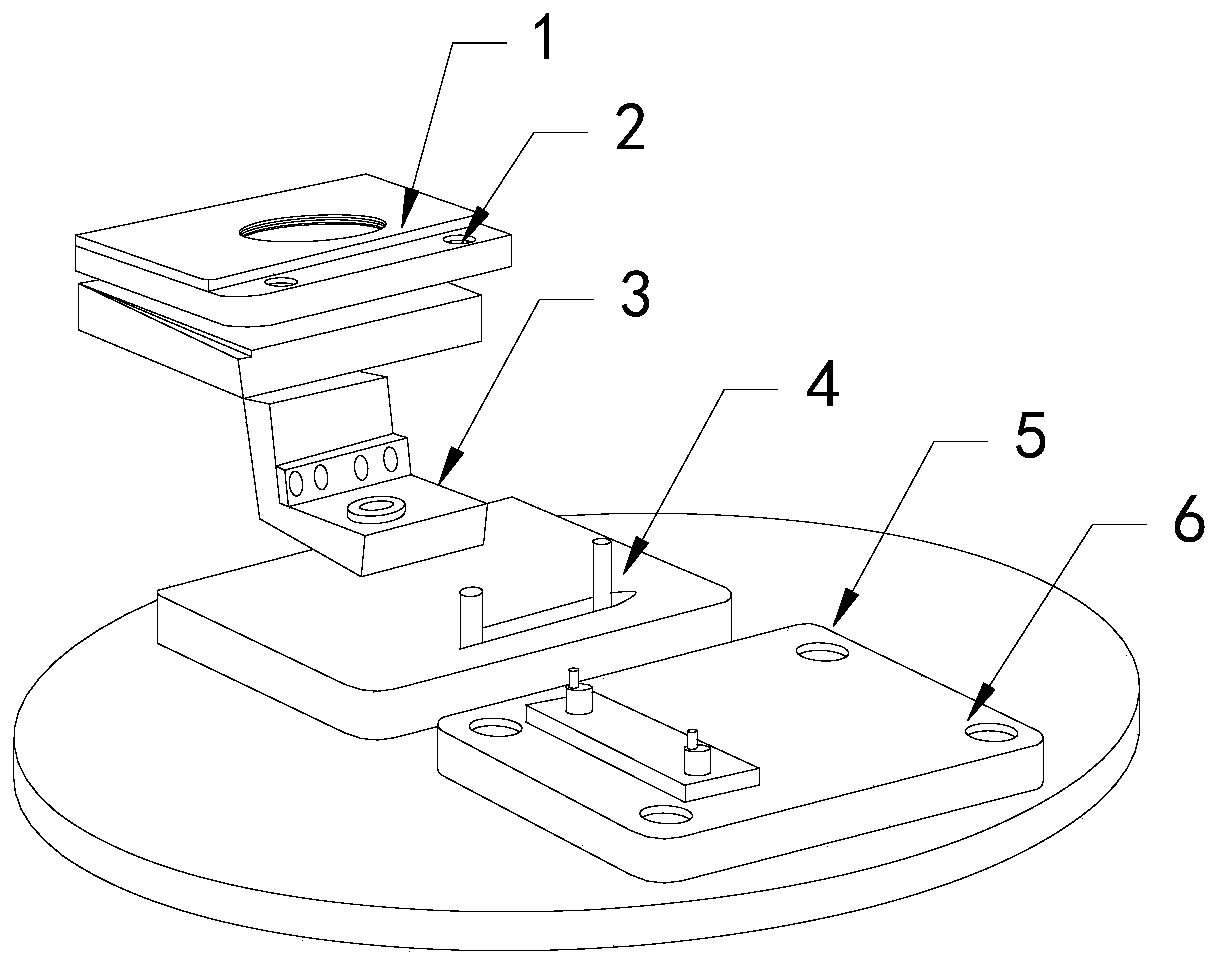

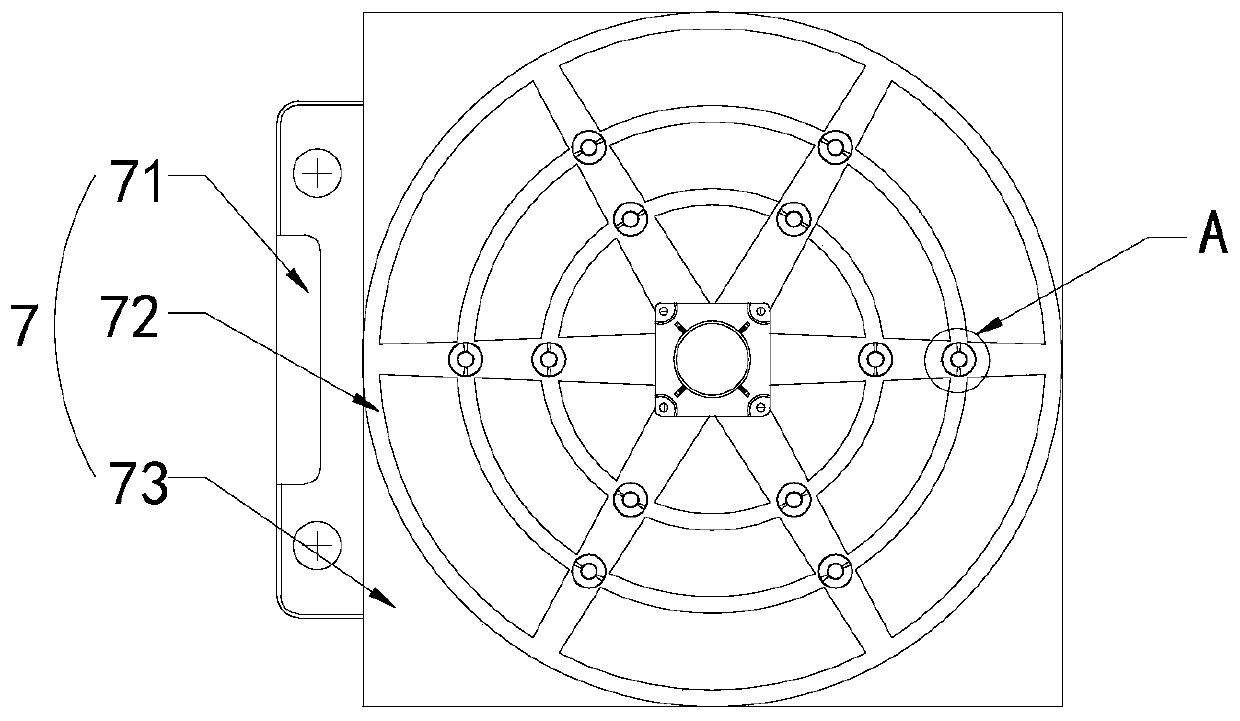

[0030] see Figure 1-Figure 7 , the present invention provides a flexible circuit board hot pressing equipment, the structure of which includes a connecting panel 1, an installation port 2, a hot pressing head 3, a first placing plate 4, a rotating chassis 5, a second placing plate 6, and a heat dissipation plate 7. The rotating chassis 5 is provided with a first placing plate 4 and a second placing plate 6, and the first placing plate 4 and the second placing plate 6 are distributed in a center-symmetric structure with respect to the center of the rotating chassis 5. There is a thermal pressure head 3, one end of the thermal pressure head 3 is installed on the joint panel 1, and an installation port 2 is opened on the side end of the joint panel 1 adjacent to the thermal pressure head 3, and the installation port 2 is provided with There is a heat dissipation plate 7, and the heat dissipation plate 7 and the thermal head 3 are parallel to each other.

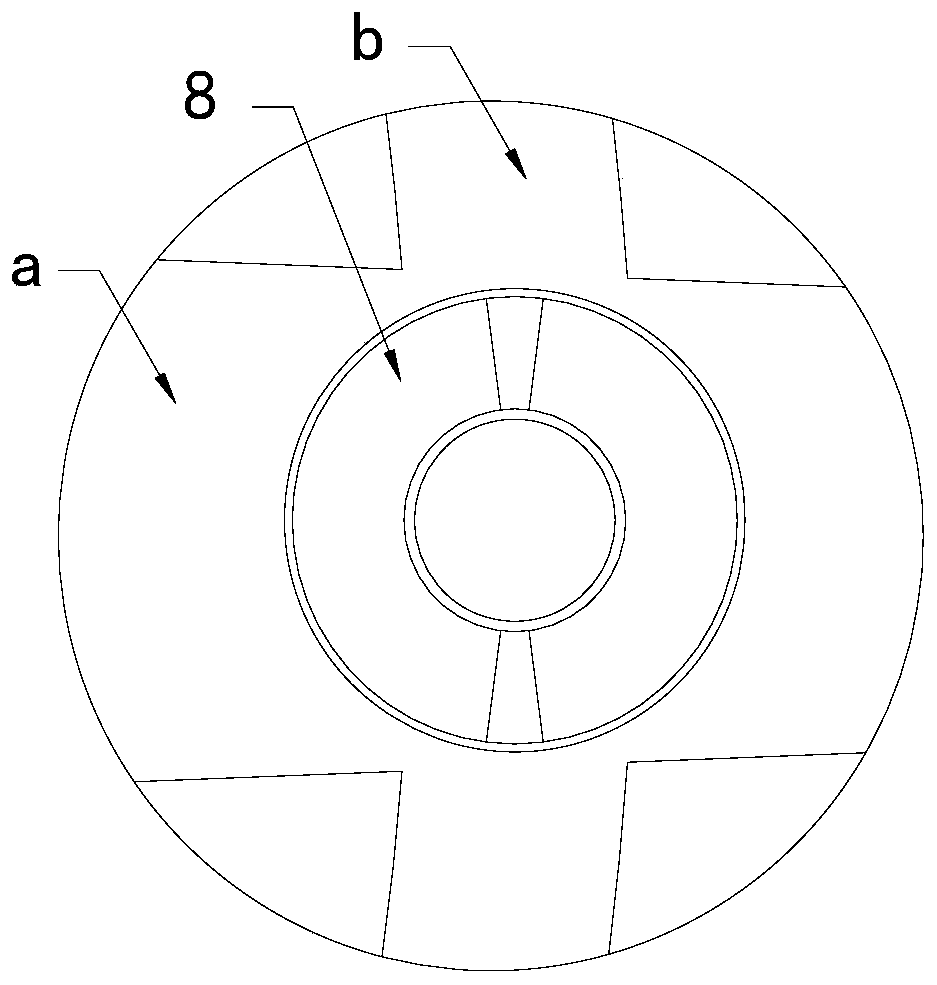

[0031] The cooling dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com