Polyimide film for flexible display device substrate

A flexible display device, polyimide film technology, applied in nonlinear optics, instruments, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] polymerization of BPDA-pPDA / PA (98.9:100:2.2) polyimide

[0074] 100 g of N-methyl-2-pyrrolidone (NMP) was charged into a reactor subjected to nitrogen flow, and 6.192 g (57.259 mmol) of p-phenylenediamine (p-PDA) were dissolved while maintaining the temperature of the reactor at 25° C. ). Add 16.661g (56.629mmol) 3,3',4,4'-biphenylcarboxylic dianhydride (s-BPDA) and 56.96g NMP to the p-PDA solution at the same temperature, and stir for a predetermined period Dissolved over time to obtain polyamic acid. To the polyamic acid solution obtained above, 0.187 g (1.260 mmol) of phthalic anhydride (PA) was added and stirred for a predetermined period of time, thereby obtaining a polyimide precursor.

[0075] An organic solvent was added to the polyimide precursor obtained above so that the solid content thereof would be 12.8% by weight to prepare a polyimide precursor solution.

[0076] Spin-coat the polyimide precursor solution onto a glass substrate. The glass substrate ...

experiment example 1

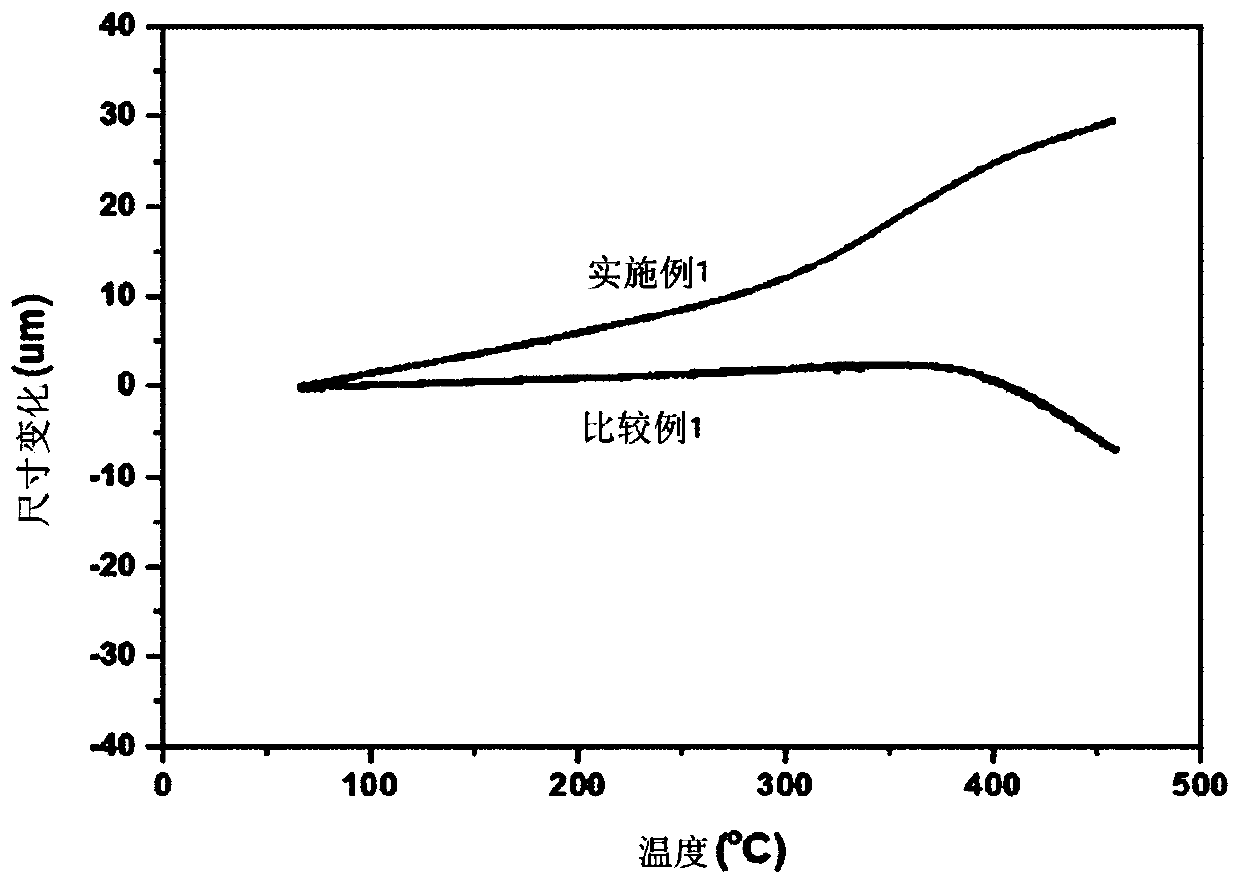

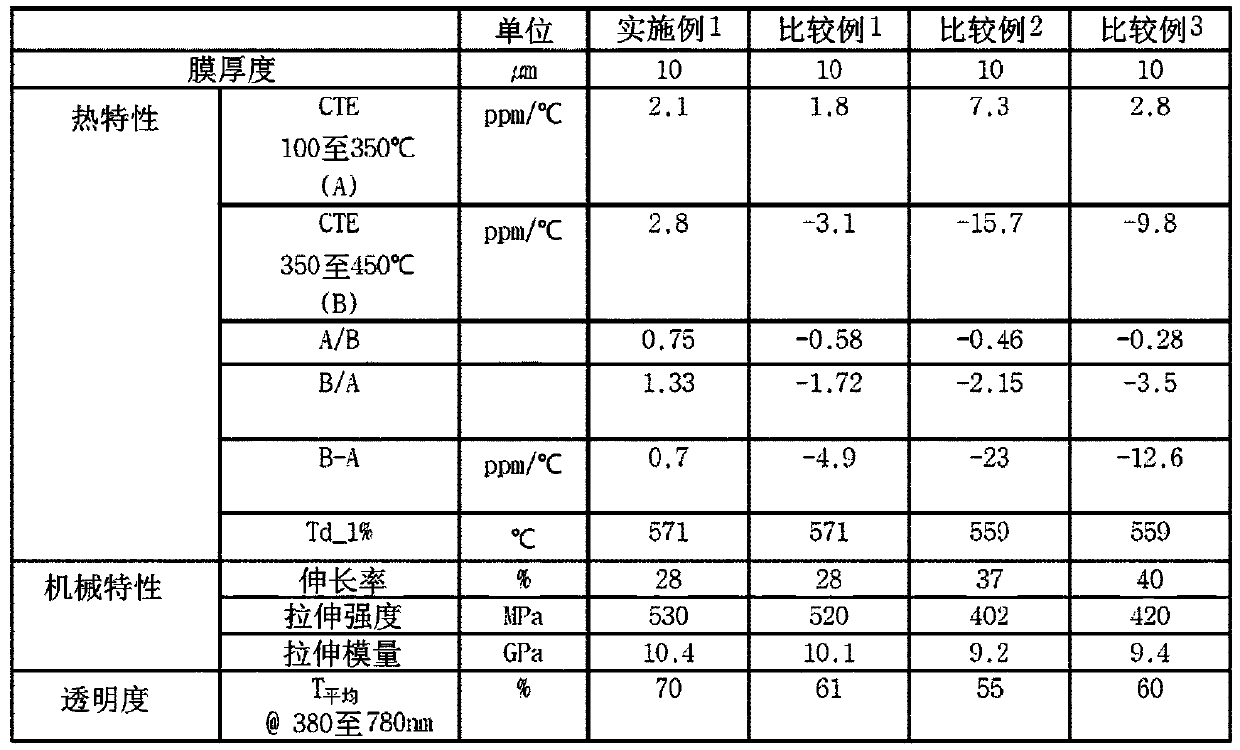

[0090] The CTE, thermal decomposition temperature, mechanical properties, and transparency of the polyimide films prepared above were measured by the following methods, and the results are shown in Table 1.

[0091]

[0092] Each of the polyimide films prepared in Examples and Comparative Examples was cut into a size of 5 mm×16 mm, and the samples were loaded in a Q400 device of TA Company using an accessory. The actual measured length of the film was 16mm, and the force to stretch the film was set at 0.02N. A first heating process was performed at a heating rate of 5°C / min in a temperature range from room temperature to 450°C, and then a cooling process was performed to 50°C at a cooling rate of 5°C / min. Then, when the cooled sample was heated at a rate of 5°C / minute in the temperature range of 50°C to 450°C, the change in thermal expansion was measured with TMA. The thermal expansion coefficients in the range of 100°C to 350°C and in the range of 350°C to 450°C and furthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thermal degradation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com