Charge-back butt joint method of cleaning equipment with laser radar and charge-back butt joint system of cleaning equipment with laser radar

A technology of cleaning equipment and laser radar, which is applied to the installation of cleaning equipment, cleaning machinery, and electrical equipment, and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

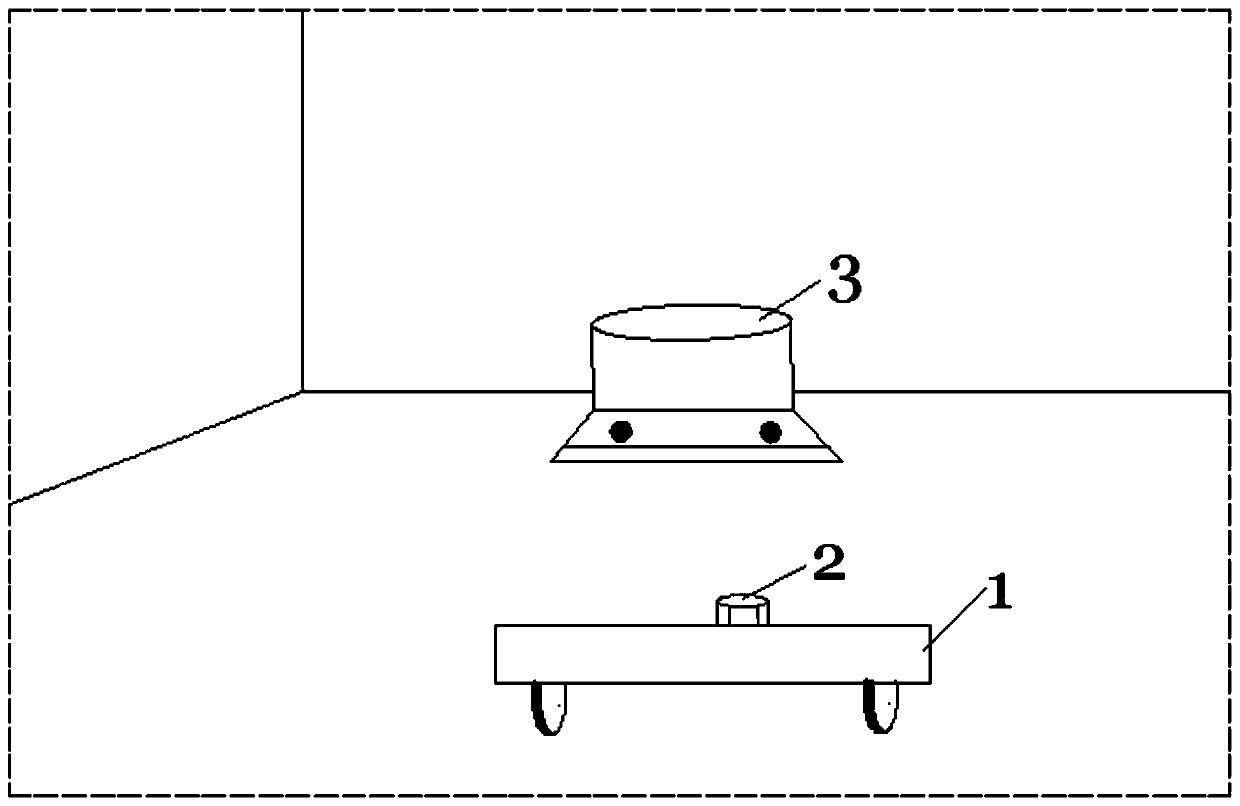

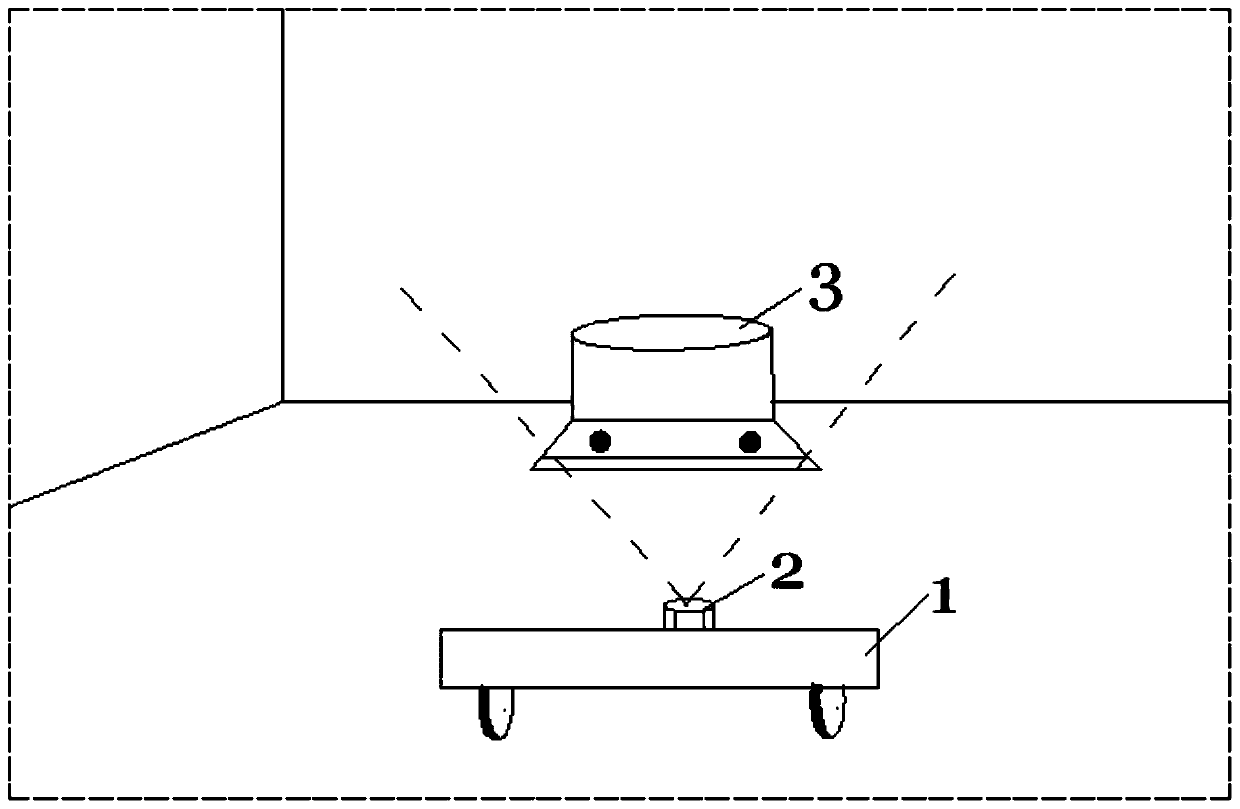

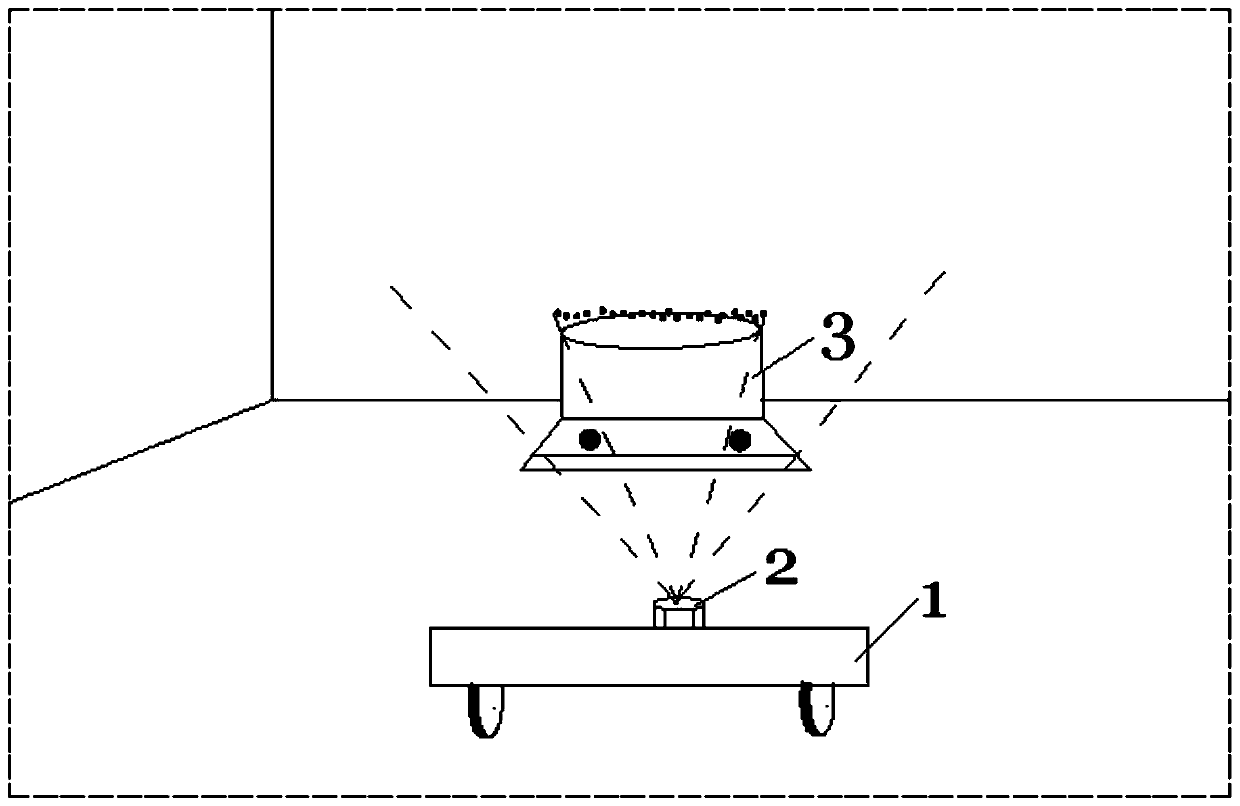

[0033] Such as Figure 1-Figure 6 , Figure 8 As shown, the present invention discloses a method for realizing recharge docking of cleaning equipment, wherein the recharge base 3 is placed close to the wall. It should be noted that the recharge base 3 does not necessarily have to be placed close to the wall, or On a board that allows the recharge stand 3 to have a backrest, etc., it can be flexibly selected and placed according to different application scenarios. The recharging station 3 can emit a recharging guidance signal that guides the cleaning device 1 to approach the recharging station 3 and dock with the recharging station 3 to complete recharging and charging. The recharging guidance signal can be an infrared guidance signal or other forms of guidance The signal is such as a wireless pilot signal. The direction of recharging is determined by the recharging guide signal obtained by the cleaning device 1 receiving sensor, and the driving module of the cleaning device ...

Embodiment 2

[0046] Such as Figure 7 , Figure 8 As shown, another embodiment of the present invention discloses a cleaning device recharging and docking system with laser radar, the recharging and docking system includes: a control module, the control module receives a control instruction to control the cleaning device to perform The control operation corresponding to the instruction; the driving module, which drives the cleaning device to move on the working space; the laser radar module, which determines the obstacles that may exist during the movement of the cleaning device and determines the recharging process during the recharging process. Seat; cleaning module, the cleaning module is configured to clean and collect the garbage on the surface of the working space, including dirt and liquid and dust on the ground; refilling module, the refilling module guides the cleaning equipment to recharge; during the refilling process Among them, the judging unit in the control module judges wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com