High-toughness fixed clamping device for automobile chassis processing

An automobile chassis, fixed clamping technology, applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of no telescopic, convenient adjustment and fixed height movement, etc., to increase the scope of application, easy to use, and improved mobility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

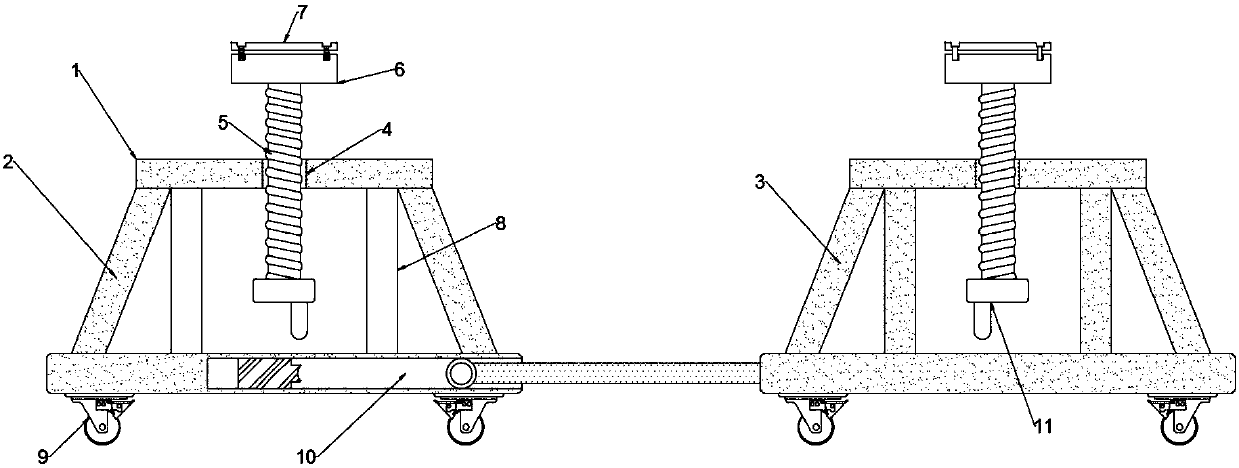

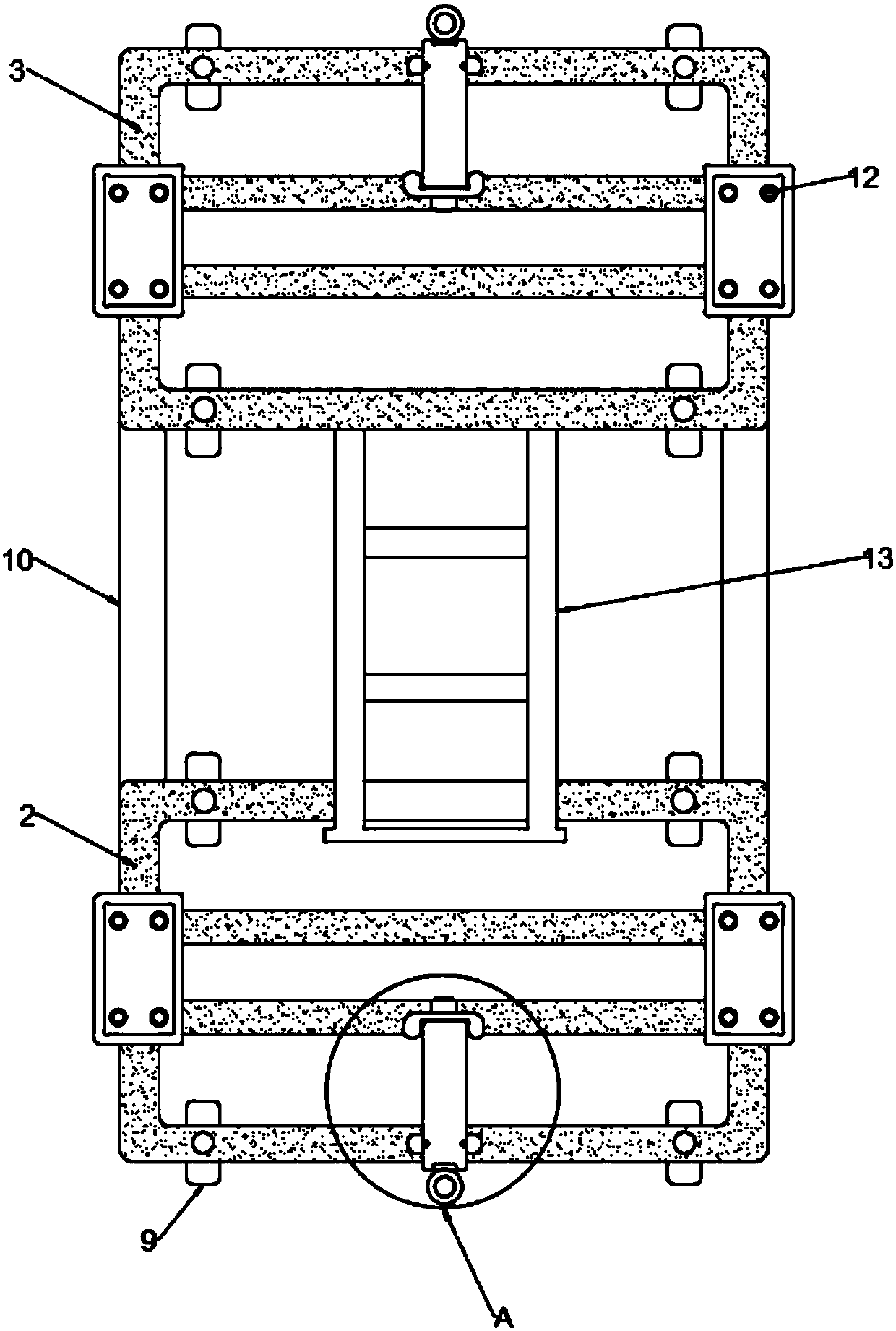

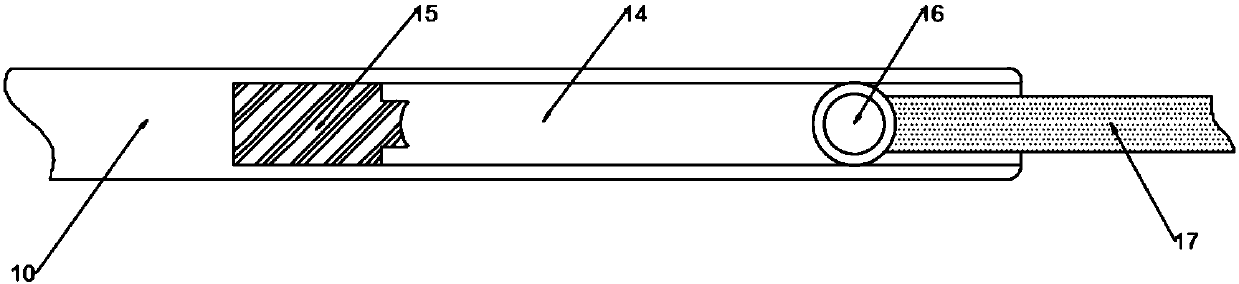

[0021] see Figure 1-5 , the present invention provides a technical solution: a fixed and clamping device for automobile chassis processing with high toughness, including a device main body 1, a first support frame 2, a second support frame 3, a threaded hole 4, a threaded rod 5, a support Plate 6, fixed plate 7, reinforcing rod 8, universal wheel 9, connecting assembly 10, hand wheel 11, fixing hole 12, connecting frame 13, pull rod 18, universal joint 19, card slot 20, fixing block 21, connecting slot 22. A chute 23, a slider 24, a spring 25 and a block 26. One side of the device body 1 is provided with a first support frame 2, and the other side of the device body 1 is provided with a second support frame 3. The first support frame 2 and the top of the second support frame 3 are provided with a threaded hole 4, the inside of the threaded hole 4 is sleeved with a threaded rod 5, the top of the threaded rod 5 is connected with a support plate 6, and the top of the support pla...

Embodiment 2

[0023] The difference from Example 1 is that the surface of the block is wrapped with a tough polyvinyl chloride material, and its raw materials and raw material parts by mass are: low-density polyvinyl chloride 10-19, polyaspartic acid ester polyurea 5 -10, polylactide 8-9, propylene oxide glycerol polyether 20-30 parts, chlorinated paraffin 5-8, epoxy stabilizer 1-5, tetrachloroisophthalonitrile 0.2-0.4, aluminum oxide 0.4 -0.6 and iron oxide 0.2-0.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com