A method for safely sealing diversion tunnels under high water head and unfavorable geological conditions in hydropower projects

A technology for hydropower engineering and geological conditions, applied in water conservancy projects, sea area engineering, construction, etc., can solve the problems of diversion tunnel plugging failure, instability, economic loss, etc., to improve the ability to resist high water head and increase the anti-friction coefficient , Improve the effect of safety assurance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] A method for safely plugging diversion tunnels under high water head and adverse geological conditions in hydropower projects, comprising the following steps:

[0031] S1. Lower gate: lower the gate 1 and gate 2 of the diversion tunnel entrance; lower the gate 1 and gate 2 of the diversion tunnel by using hoisting system, door crane or automobile crawler crane. Do a good job of dredging the gate groove before opening the gate to ensure that the gate can be opened smoothly. Divers can be used to clean up with mud pumps and high-pressure air pipes;

[0032] S2. Pumping water: After the gate is lowered, the drainage pontoons equipped with water pumps are transferred to the inside of the diversion tunnel inlet gate 1 and outlet gate 2 to pump water at the same time, and the water in the diversion tunnel is drained;

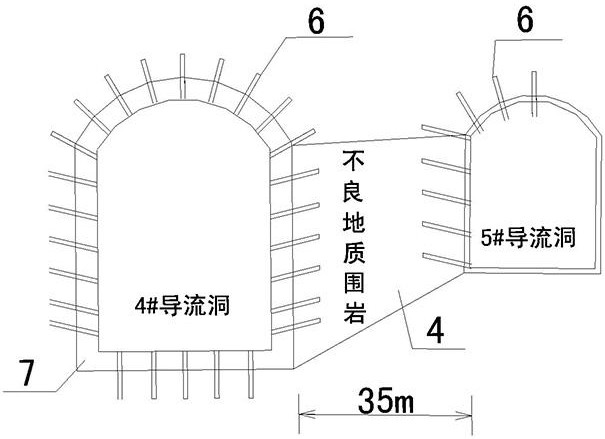

[0033] S3. Plugging: including the construction of safety protection plug 3, the reinforcement construction of surrounding rock 4 in unfavorable geological sec...

experiment example

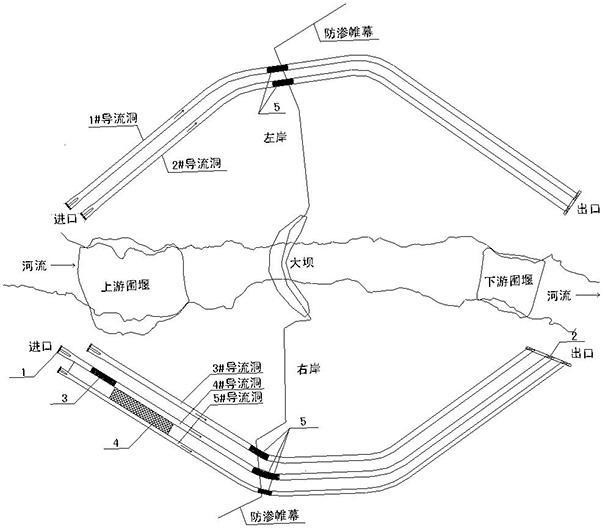

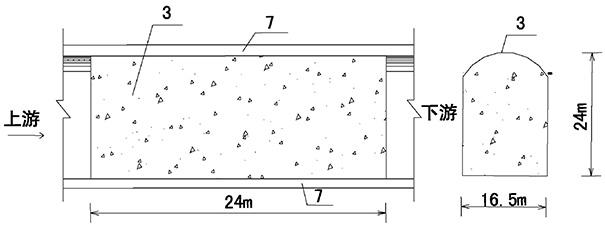

[0042] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the hydropower project is arranged with 5 diversion tunnels, that is, the left bank 1 # ,2 # Diversion Tunnel and Right Bank 3 # 、4 # 、5 # diversion tunnel, where the left bank 1 # ,2 # and Right Bank 3 # 、4 # The size of the cross-section of the diversion tunnel is 16.5m×24.0m, and the right bank 5 # The size of the cross-section of the diversion tunnel is 12.0m×16.0m, and the cross-sections of the five diversion tunnels are all in the shape of a city gate; the upstream design water retaining head during the closure period of the diversion tunnel is 108.88m, and the upstream design water head is 172m after the power station is in operation , according to the geological conditions of the diversion tunnel, the closing sequence of the lower gate is 4 # →3 # →1 # →2 # →5 # The diversion tunnel needs to be completed in a dry season (7 months), and the water level gradually rises during the closu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com