Multifunctional test equipment for mobile terminals

A multi-functional testing, mobile terminal technology, applied in branch equipment, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of increasing equipment input costs, difficult to control the overall quality, and increasing labor costs, etc. Improve the convenience of testing, facilitate multi-directional testing, improve work efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

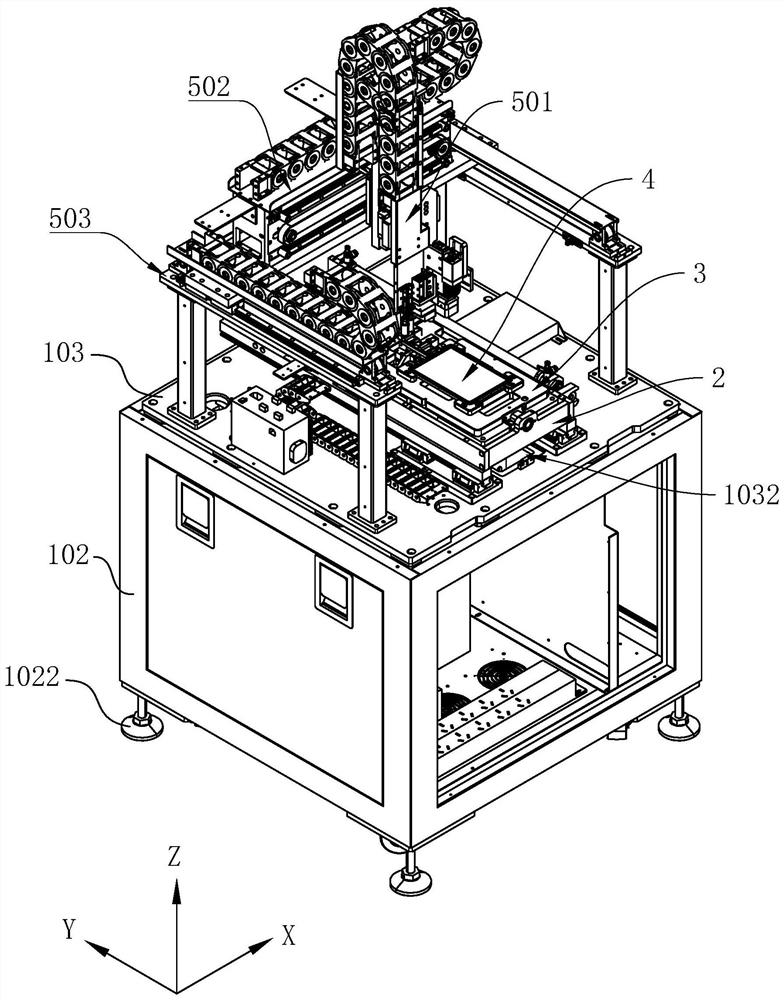

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

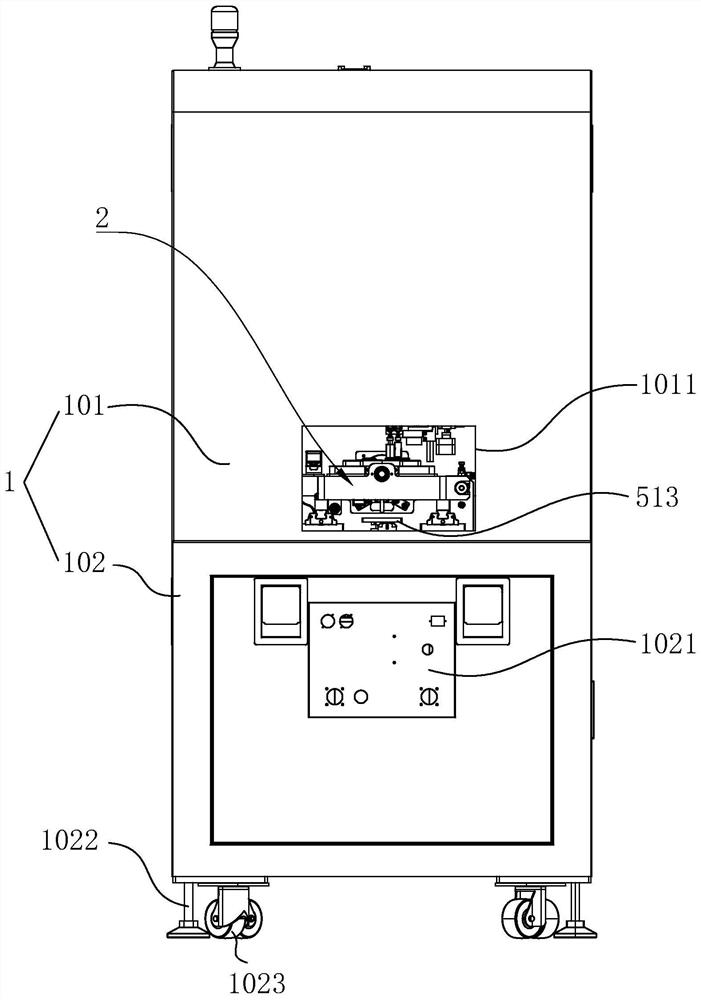

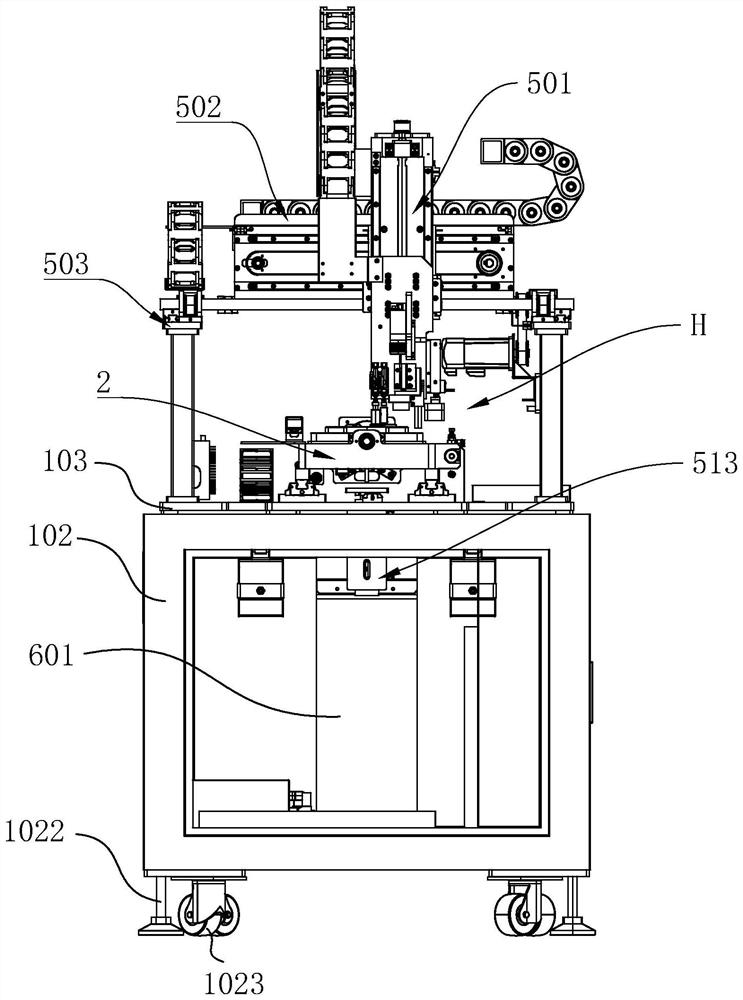

[0044] refer to Figure 1 to Figure 4 , a mobile terminal 4 multi-functional testing equipment disclosed in the present invention includes a box body 1, a carrier moving device 2 for positioning a carrier 3 loaded with a mobile terminal 4 and driving the carrier 3 to move, A test device for functional testing of the mobile terminal 4 and a control system for controlling the operation of the entire device.

[0045] The box body includes an upper box body 101, a lower box body 102, and a horizontal support plate 103 arranged between the upper and lower box bodies to separate the inner space of the upper and lower box body into two independent spaces. The horizontal support plate 103 of the present embodiment is detachable. The way is fixed between the upper and lower boxes, such as bolts.

[0046] The carrier moving device 2 is located in the upper box body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com