Multi-machine power system self-adaptive fuzzy dynamic surface sliding mode control method capable of meeting preset output tracking performance

An electromechanical system, self-adaptive fuzzy technology, applied in self-adaptive control, flexible AC transmission system, general control system, etc., can solve problems without considering connection and interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

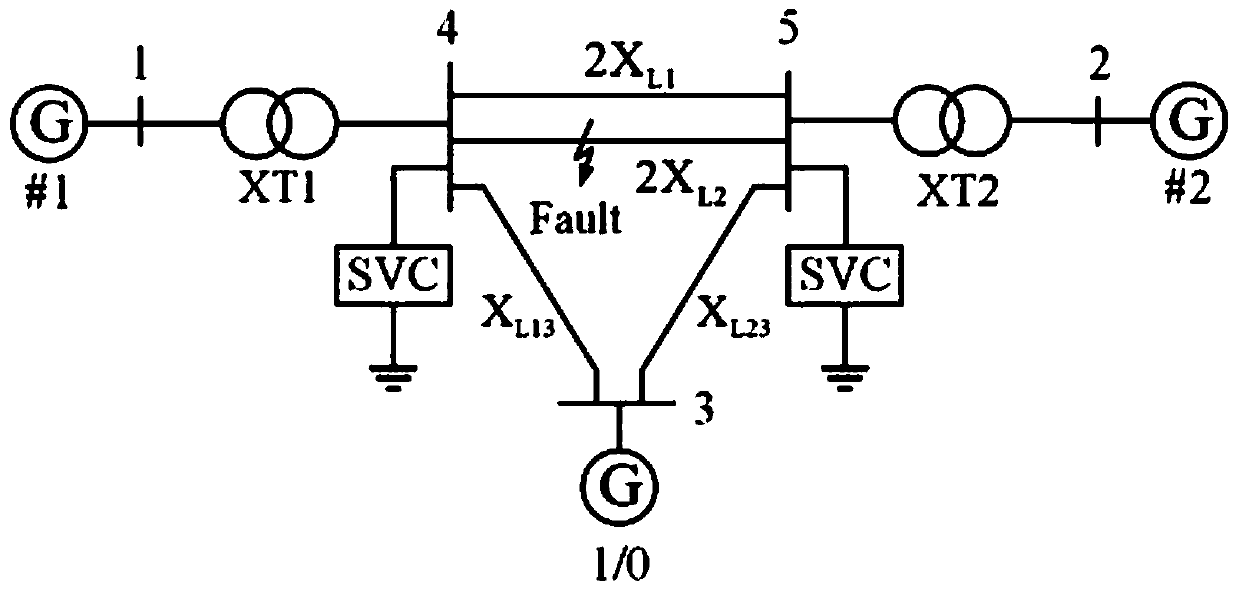

[0336] The actual operating point is selected as: δ 10 =40.415°,ω 10 =100.02πrad / s, P m10 =1.02p.u.,V ref1 =1.15p.u.,δ 20 =40.285°,ω 20 =99.98πrad / s,P m20 =0.98p.u.,V ref2 = 1.05 p.u..

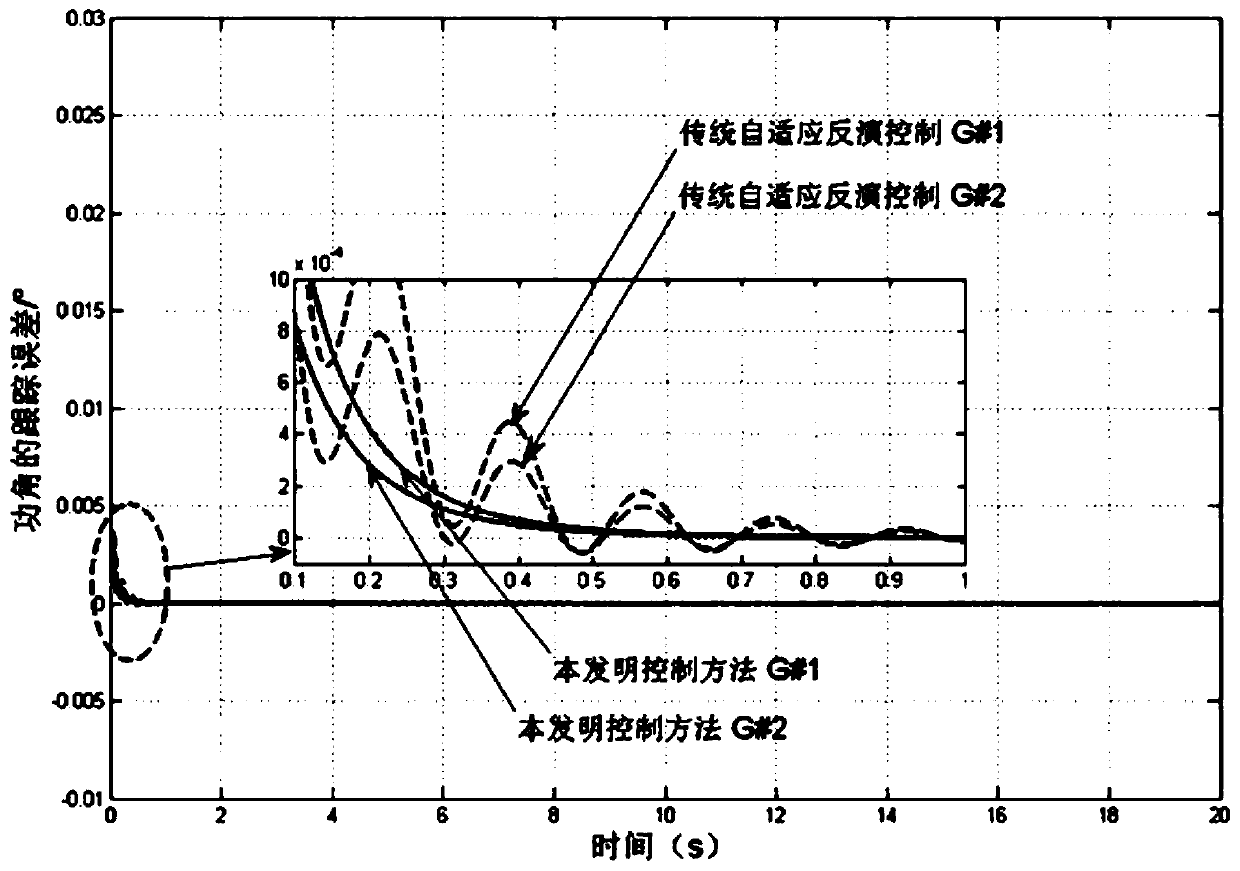

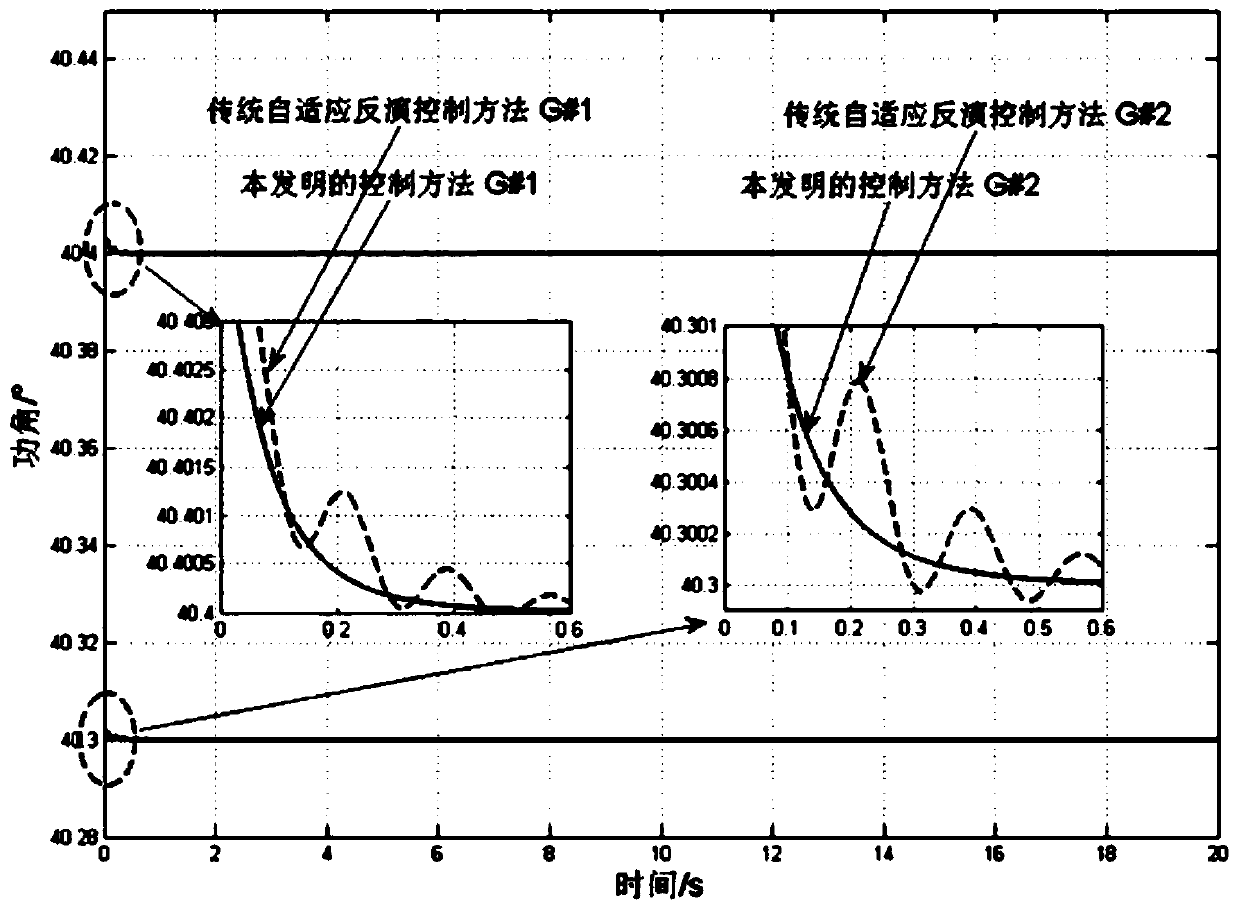

[0337] The simulation results of Example 1 are shown in Figure (2-7).

[0338] figure 2 The power angle tracking error of the proposed method and the power angle tracking error of the conventional adaptive inversion method are shown. The control law of the traditional adaptive inversion method is

[0339]

[0340] It can be seen that the method of the present invention is much simpler than the traditional self-adaptive inversion method, and the power angle tracking error is always kept within the predetermined tracking performance curve.

[0341] Correspondingly, the maximum and root mean square values of the tracking errors in the steady state (t>900ms) of the two control schemes are shown in Table 2. It can be seen that the method proposed in this paper has the characteristi...

example 2

[0346] The operating point is selected as: δ 10 =40.4015°,ω 10 =100.04πrad / s,P m10 = 1.01 p.u., V ref1 = 1.15 p.u., δ 20 =40.2085°,ω 20 =100.05πrad / s,P m20 =1.018p.u.,V ref2 = 1.05 p.u. In order to verify the effectiveness of the method proposed in this paper for the dual-machine power system with SVC equipment, it is assumed that during the operation of the system, a three-phase voltage short-circuit fault suddenly occurs at t=4.8s and disappears after a duration of 0.4 seconds.

[0347] Simulation results such as Figure 8-14 . Figure 8 For the power angle tracking error between the proposed method and the traditional adaptive inversion method in the case of short-circuit interference. The steady-state MVTE and RMSVTE of the two control methods are shown in Table 3. It can be seen that the control effect of this method is better than that of the traditional adaptive inversion method. Figure 9-11 The curves of power angle, rotational speed and electric power of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com