Electric drive bench test system on-line fault protection method based on real-time control bus

A technology for bench testing and real-time control, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., can solve the problems of inability to realize coordinated logical protection of monitoring data, fast response time, and lack of flexibility. Achieve high reliability, fast response, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

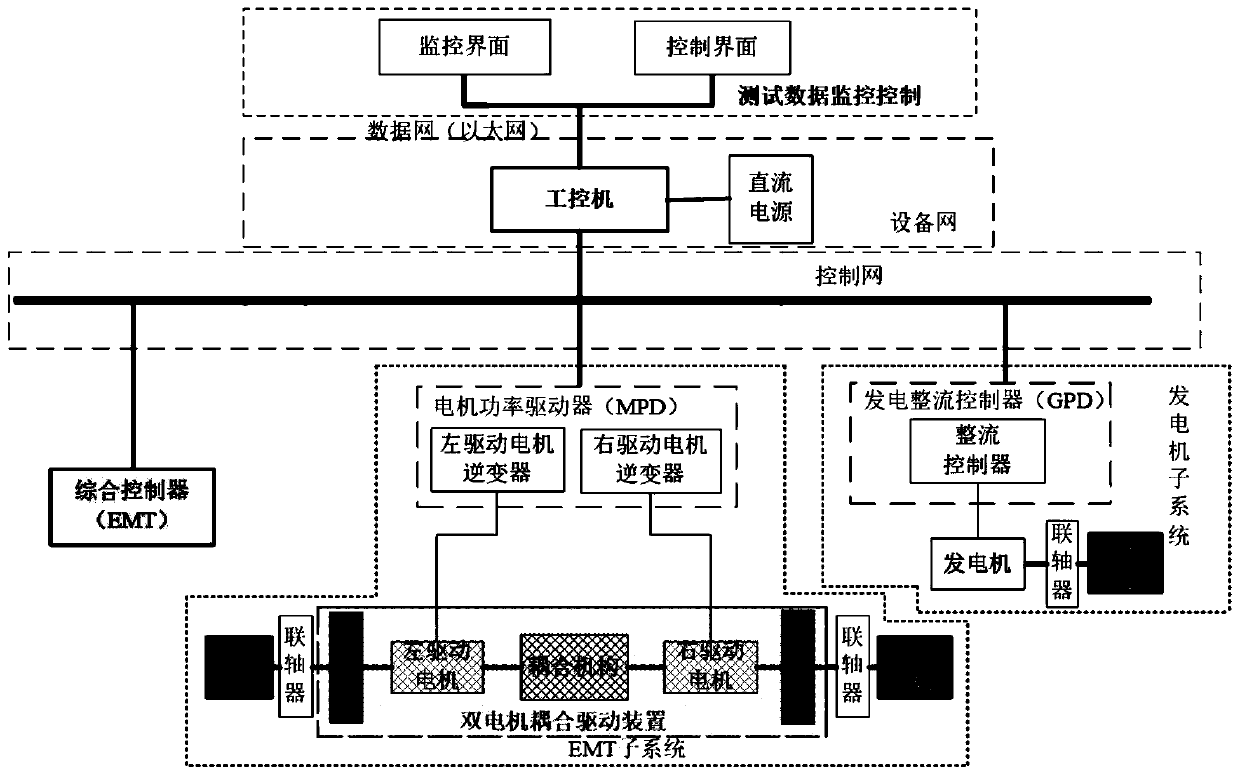

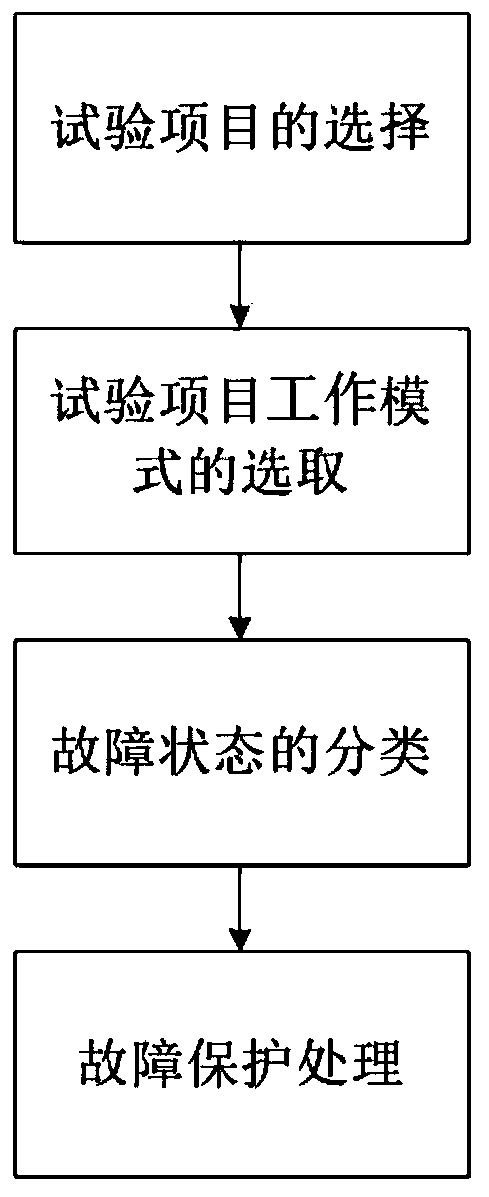

[0026] This embodiment provides an online fault protection method for an electric drive bench test system with a real-time control bus, such as figure 1 As shown, the network architecture of the electric transmission bench test system is composed of a control network, a data monitoring network, and a device network. The control network not only includes the CAN bus control network, but also applies to all real-time control bus networks including FlexRay, TTE, TTCAN, etc. High-speed real-time network.

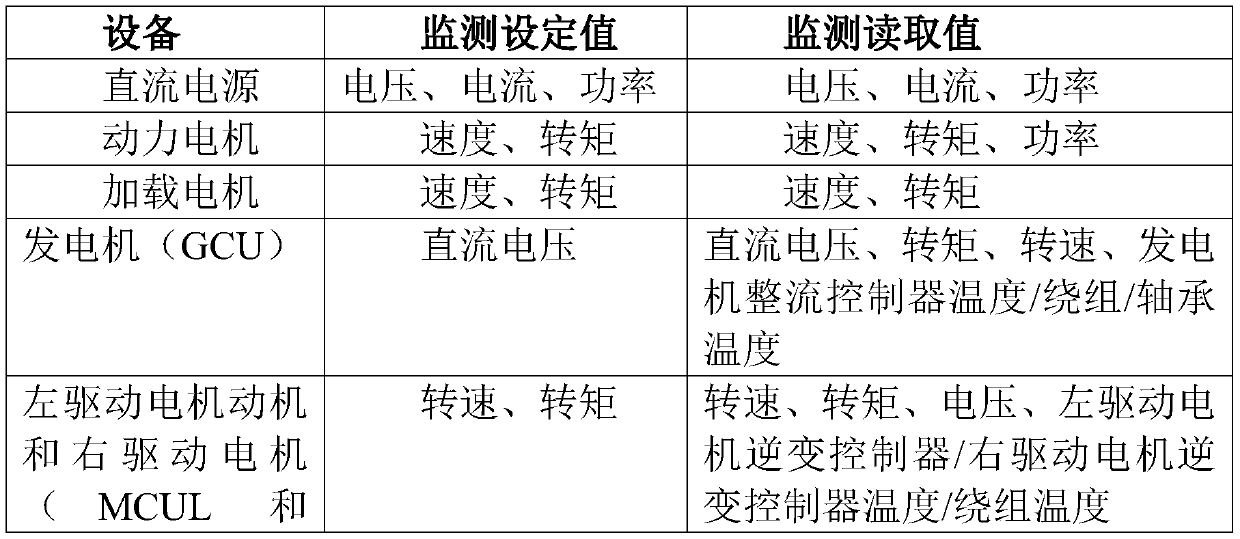

[0027] The integrated controller (EMT) is the control core of the entire electric drive bench test system. Its main function is to coordinate the collaborative work of other test equipment in the electric drive bench test system through bus communication, accept the control commands issued by the man-machine control interface, and Communicate with the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com