Preparation method of luminescent device as well as luminescent device and display panel

A light-emitting device, one-sided technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of short life and low luminous efficiency, and achieve the effect of increasing mobility, improving luminous efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

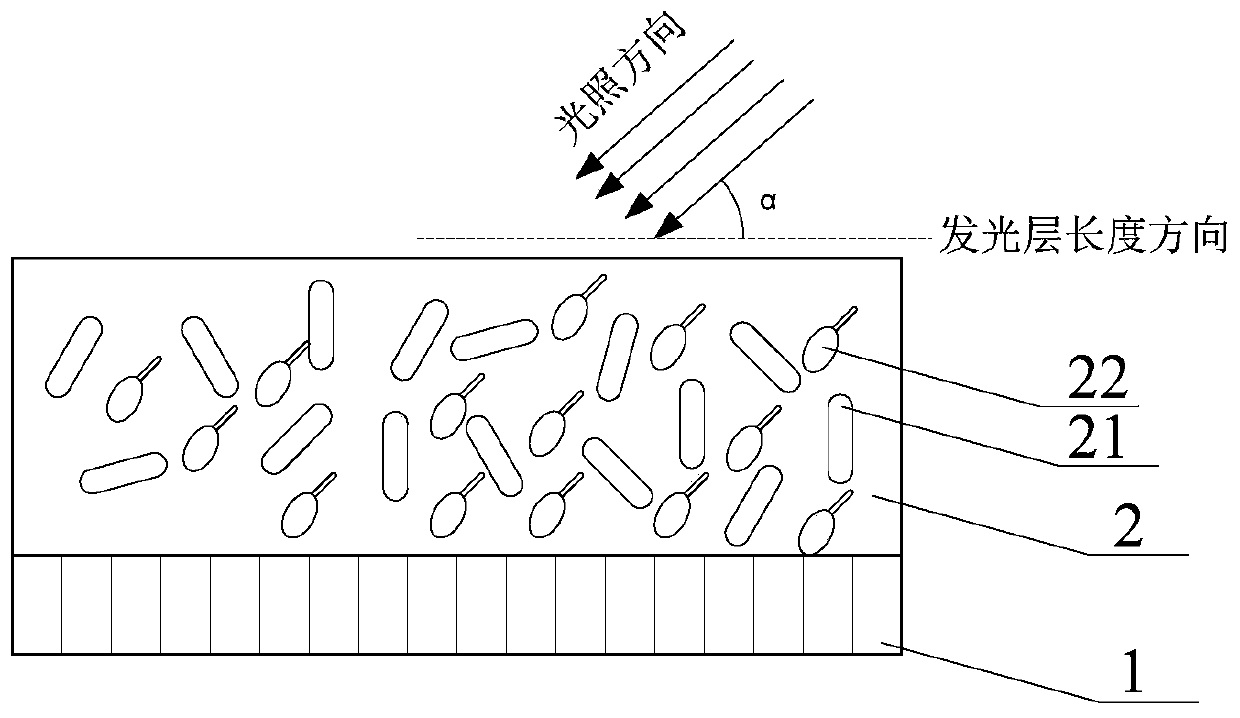

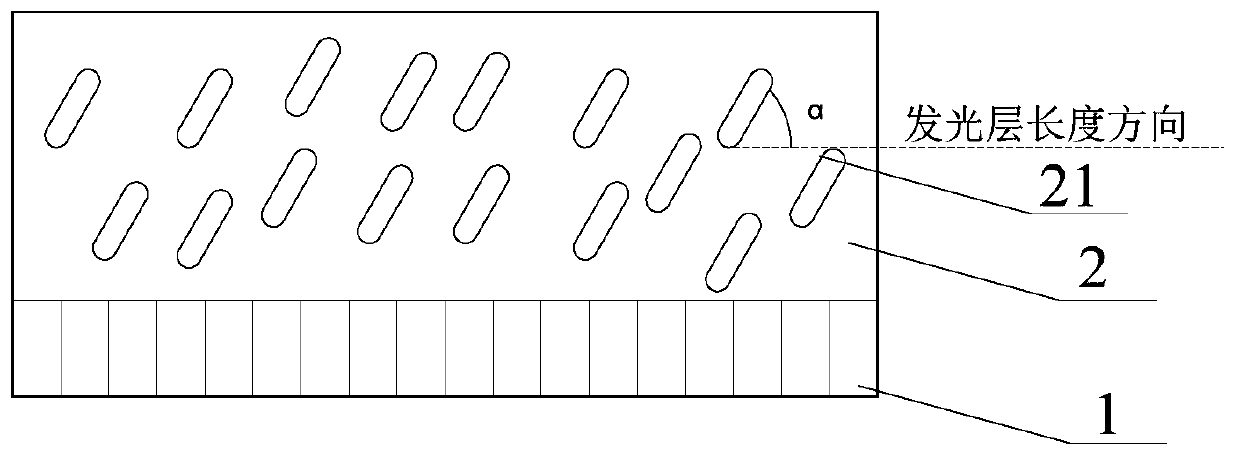

[0020] As mentioned in the background technology, the light-emitting layer in the light-emitting device in the prior art is printed by inkjet, but the luminous efficiency of the light-emitting layer is low and the service life is short. The arrangement of the organic light-emitting materials in the light-emitting layer formed by ink printing is disordered, which leads to the decrease of the mobility of electrons and holes in the organic light-emitting materials, thus reducing the luminous efficiency of the light-emitting layer and shortening the service life of the light-emitting layer .

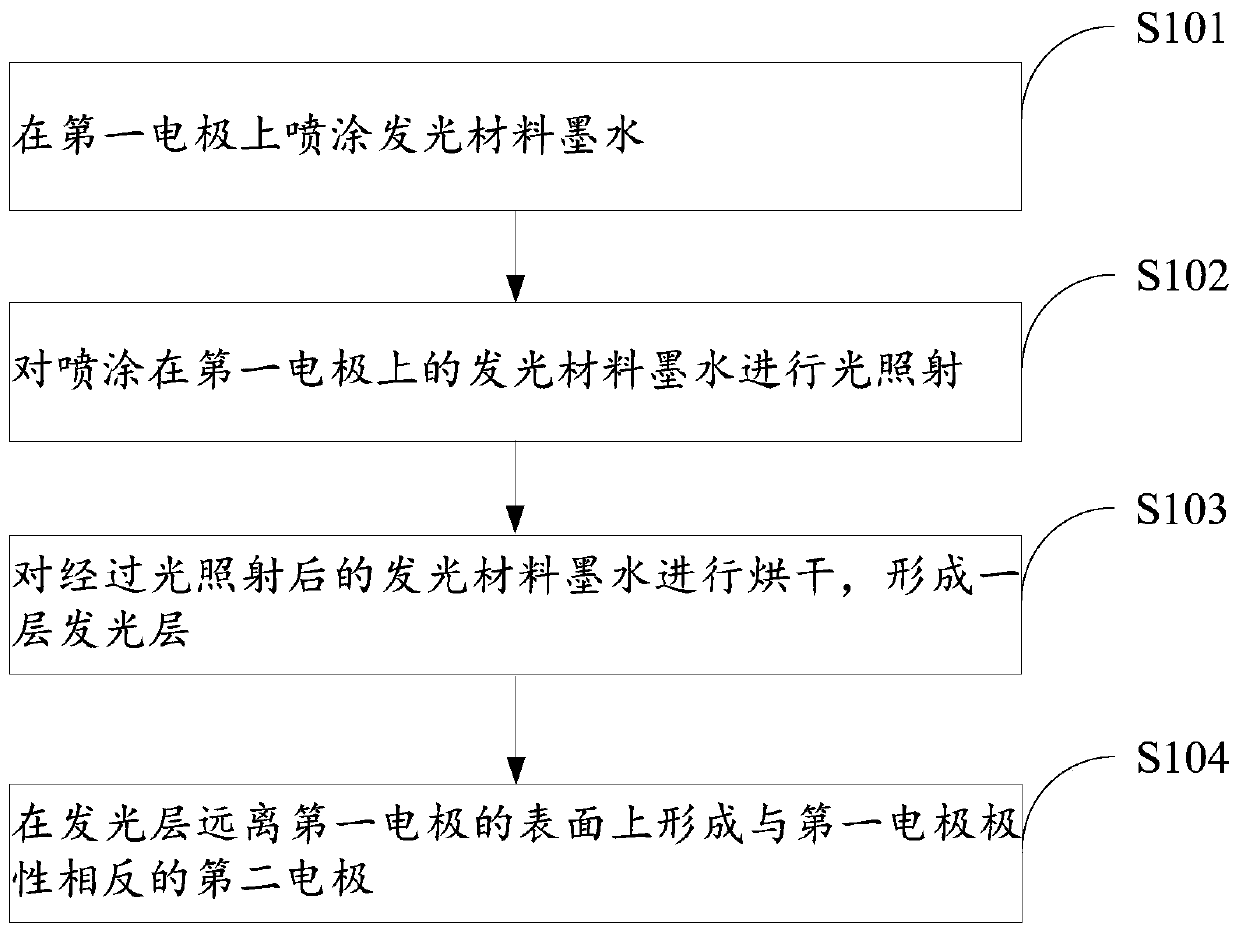

[0021] Based on this, the present invention provides a method for preparing a light-emitting device. An auxiliary agent is added to the ink used for inkjet printing of the light-emitting layer, and the auxiliary agent can be aligned under light irradiation, so that the organic light-emitting material The van der Waals force between the organic molecules and the auxiliary molecules enables th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com