Extrusion filter and efficient extrusion filtering assembly adopting same

A filter and component technology, applied in the field of extrusion filter and high-efficiency extrusion filter component, can solve the problems of weak strength, influence on drinking taste, unstable injection size of parts, etc., and achieve easy forming and demoulding, good filtering effect, The effect of practical operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

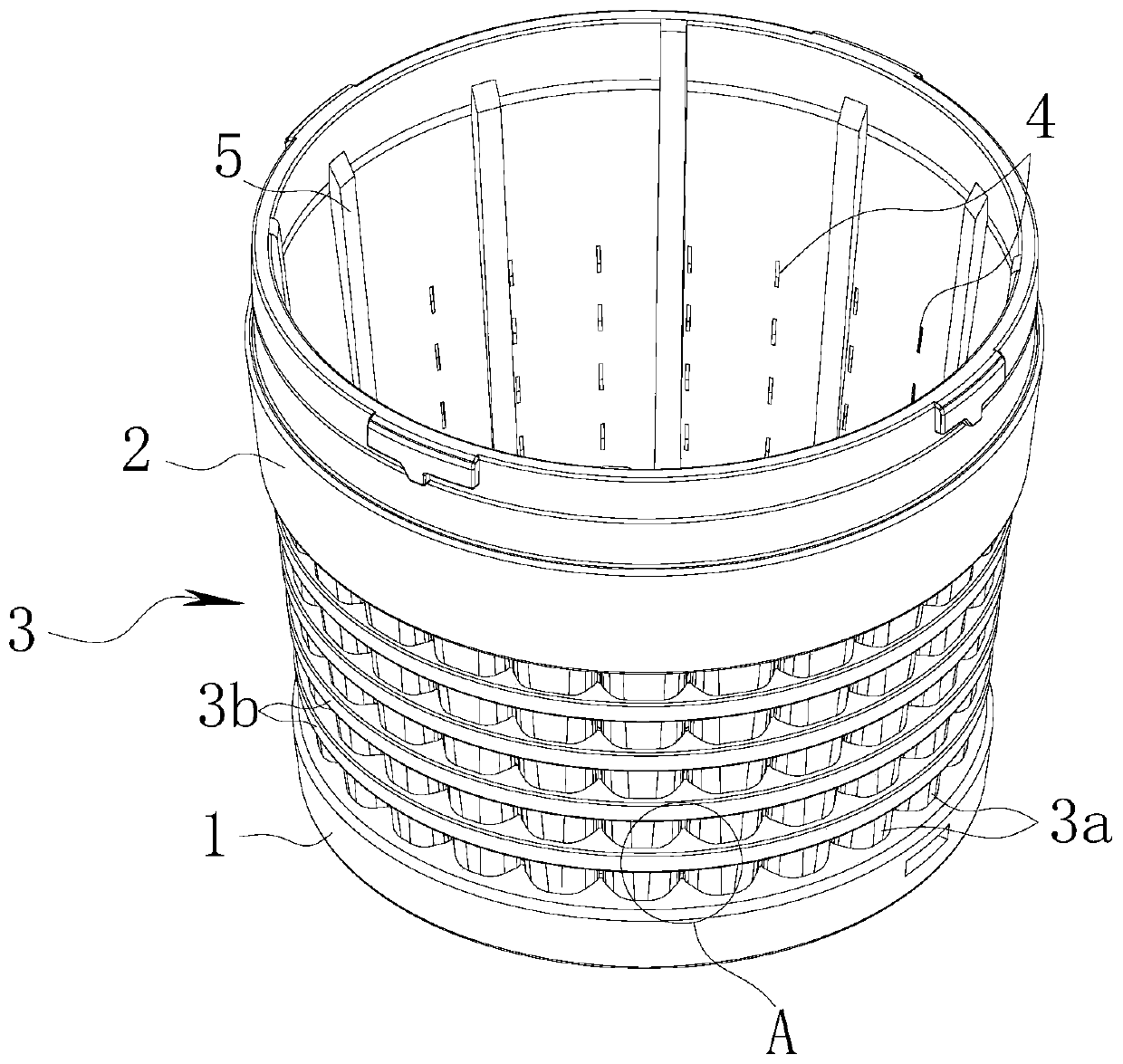

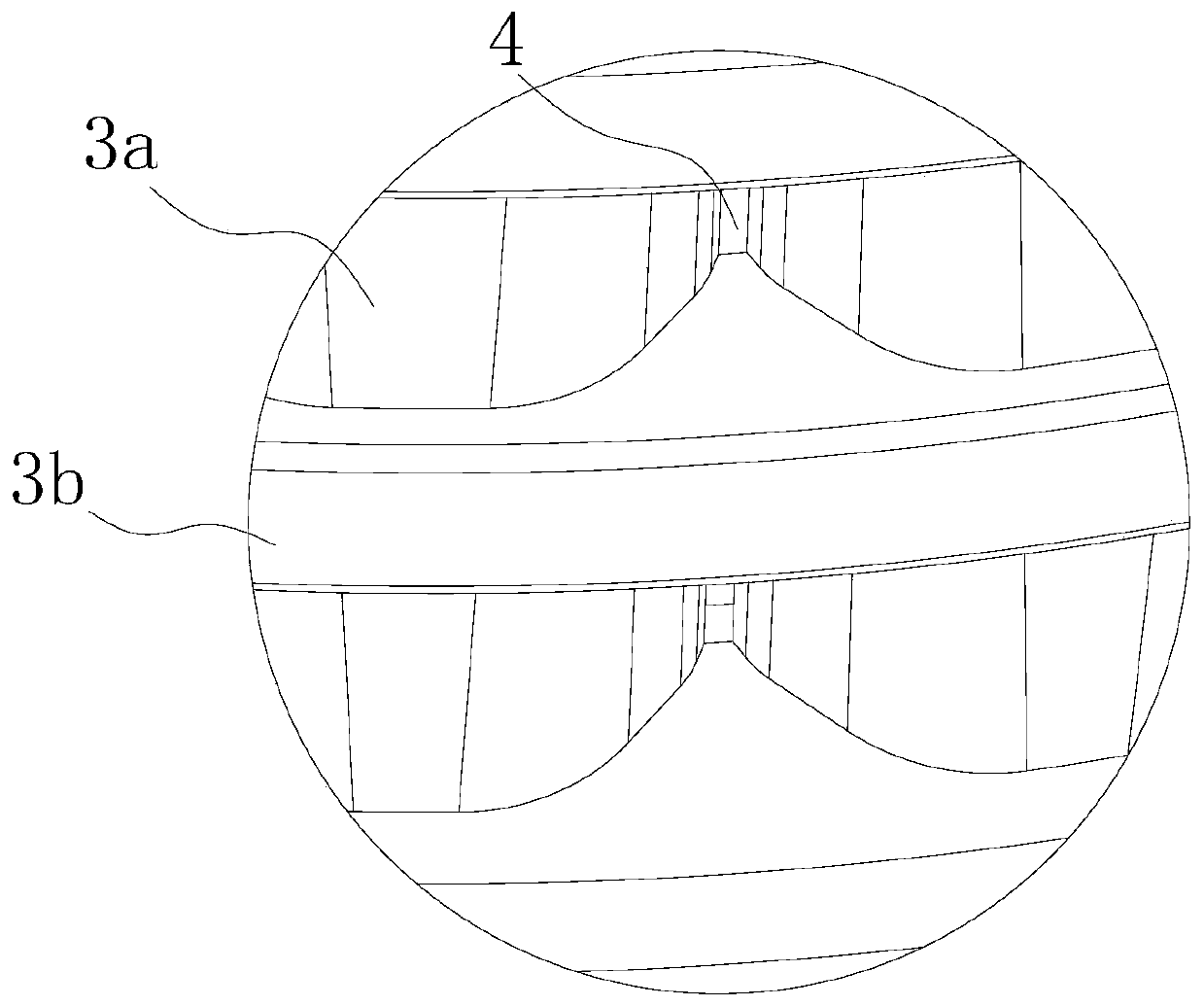

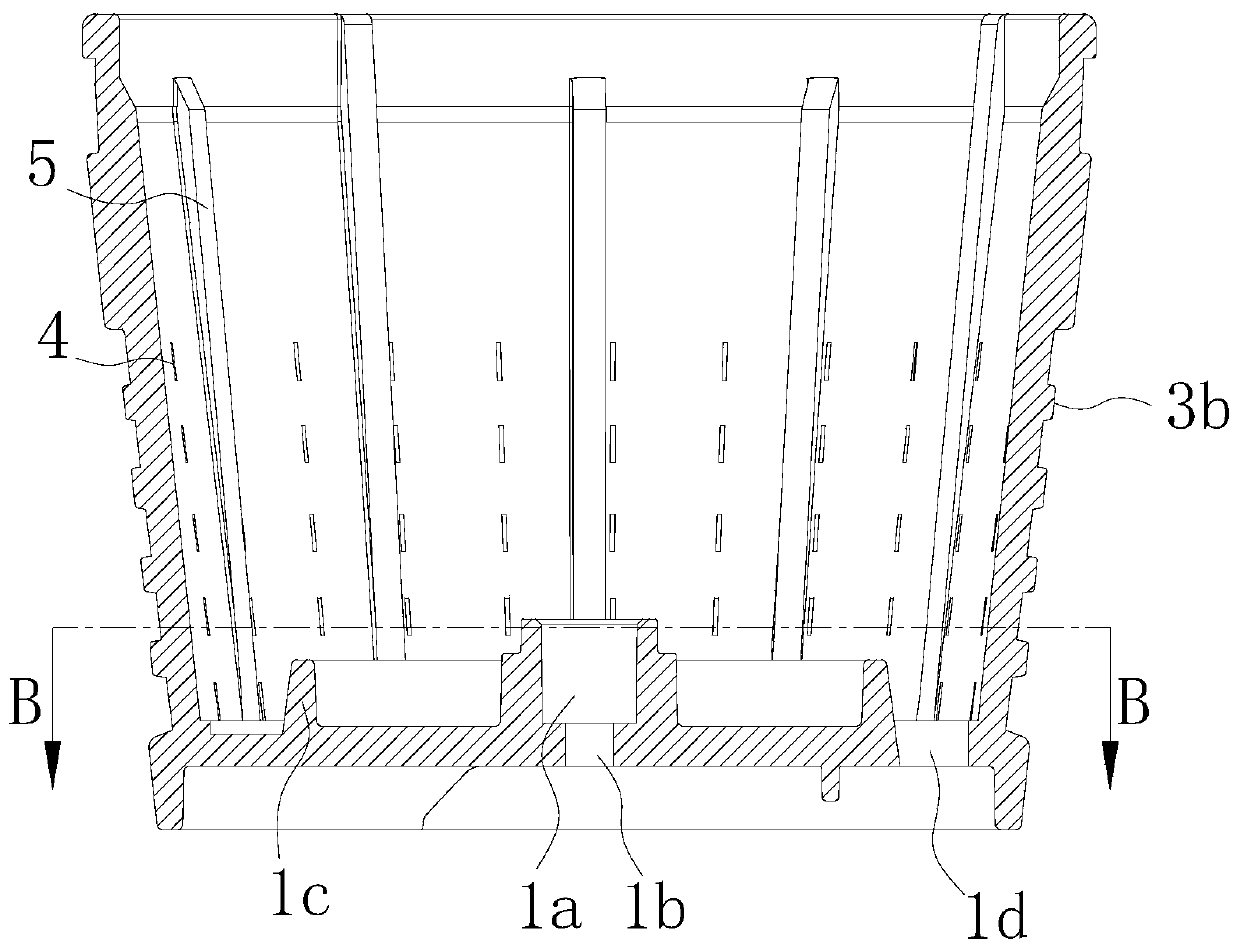

[0037] refer to Figure 1 to Figure 5 As shown, a squeeze filter of the present invention includes a base 1, a connecting ring 2 is arranged above the base 1, and an annular filter part 3 is connected between the base 1 and the connecting ring 2. On the annular filter part 3 Several filter holes 4 are distributed, and the diameter of the juice inlet end of the filter holes 4 is smaller than the diameter of the juice outlet end. The longest length of each filter hole 4 is 3-12 mm, and the widest point is 0.25-0.55 mm. Preferably, the base, the connecting ring and the annular filter part are an injection-molded integral structure. Compared with the structure of split type or stainless steel filter combined with plastic skeleton, it has the obvious advantages of simple structure, convenient processing, low cost, good stability, safety and environmental protection.

[0038]After repeated experiments, it was found that if the filter hole is within the parameter range, the filtere...

Embodiment 2

[0046] refer to Image 6 As shown, a squeeze filter of the present invention has basically the same structure as that of Embodiment 1, except that the height of the connecting ring is lengthened and the structure of the bottom of the base is different. Specifically, a relief through hole 1e is provided in the middle of the base 1 . A second sealing ring 1f is provided at the opening of the upper end of the relief through hole 1e, and a second output hole 1g is provided on the base 1 outside the second sealing ring 1f.

[0047] The structure is suitable for a bottom-driven juice extractor or juice residue separation equipment. The motor positioned at the bottom of the cup body 1 passes through the relief through hole to interlock with the screw propeller in the cup body.

[0048] refer to Figure 7 As shown, the squeeze filter of the present invention cooperates with the screw propeller of the existing juice extractor to form a double juice outlet structure, and only needs t...

Embodiment 3

[0050] refer to Figure 8 to Figure 10 As shown, a squeeze filter of the present invention has basically the same structure as that of Embodiment 1, except that there is no first squeeze grinding rib 5 in the annular filter portion 3 . A relief through hole is provided in the middle of the base, so that the base has a circular structure. At the same time, when each second connecting rib 3b is obliquely arranged and uniformly distributed along the circumferential direction of the annular filter part 3, the thread lead angle of each second connecting rib 3b is 12-30°, and the distance between two adjacent second connecting ribs 3b is 6-30°. 12mm. In this embodiment, the second connecting rib protrudes outside each first connecting rib 3a, which not only has the function of connecting each first connecting rib to improve the stability of the first connecting rib, but also cooperates with the first connecting rib When the filter hole is formed, it is also used as a spiral extrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com