Pre-treatment technology of color-coated plate with high adhesive force

A high-adhesion, color-coated board technology, used in pretreatment surfaces, coatings, devices for coating liquids on surfaces, etc. To achieve the effect of excellent adhesion performance, adhesion performance improvement, scratch resistance performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

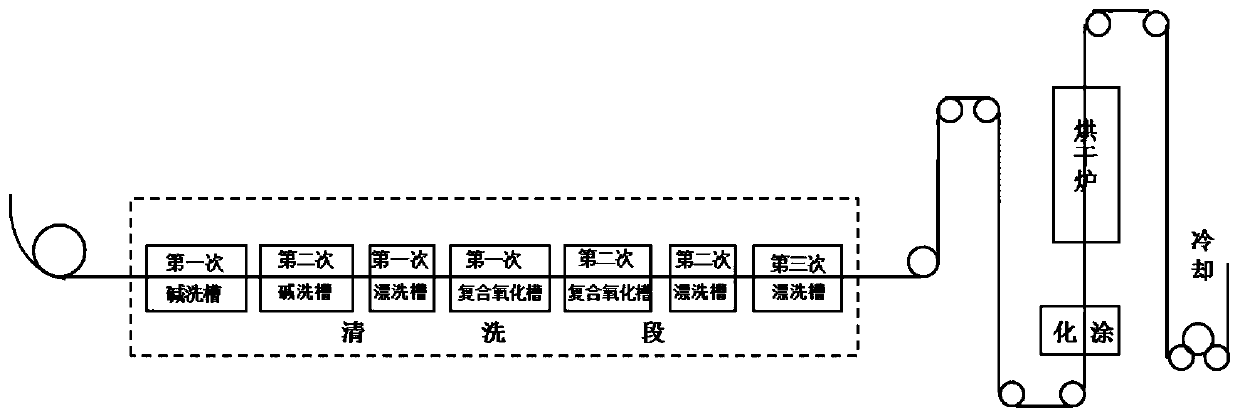

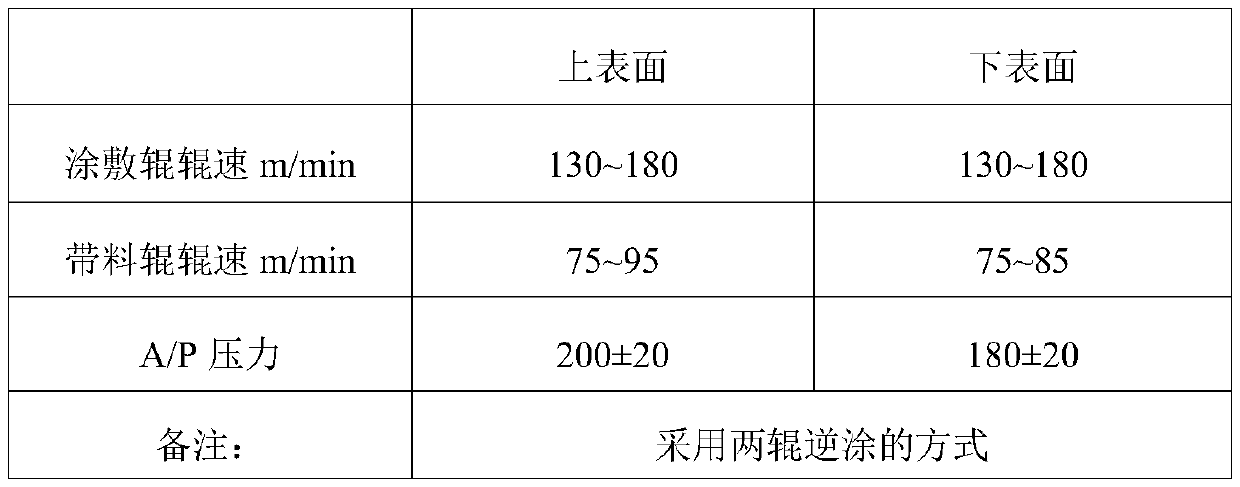

Method used

Image

Examples

Embodiment 1

[0057] The free alkali in the first alkali washing tank is 3.23, the alkali ratio is 1.34, the conductivity is 8.9ms / cm, and the temperature is 55.8°C;

[0058] The free alkali in the second alkali washing tank is 2.82, the alkali ratio is 1.21, the conductivity is 7.8ms / cm, and the temperature is 55.8°C;

[0059] The total alkali of the first hot water rinse tank is 1.22, the conductivity is 100.5ms / cm, and the temperature is 53.8°C;

[0060] The free alkali of the first composite oxidation tank is 5.31, the alkali ratio is 1.25, the conductivity is 52.1ms / cm, and the temperature is 54.4°C;

[0061] The free base of the second composite oxidation tank is 6.41, the base ratio is 1.2, the conductivity is 57.6ms / cm, and the temperature is 50.8°C;

[0062] The total alkali of the second hot water rinse tank is 0.82, the conductivity is 384.5μs / cm, and the temperature is 53.8℃;

[0063] The total alkali of the third hot water rinse tank is 0.09, the conductivity is 23.5μs / cm, and ...

Embodiment 2

[0066] The free alkali in the first alkali washing tank is 3.56, the alkali ratio is 1.24, the conductivity is 9.1ms / cm, and the temperature is 55.2°C;

[0067] The free alkali in the second alkali washing tank is 3.09, the alkali ratio is 1.11, the conductivity is 8.2ms / cm, and the temperature is 54.8°C;

[0068] The total alkali of the first hot water rinse tank is 1.29, the conductivity is 99.8ms / cm, and the temperature is 52.9°C;

[0069] The free alkali of the first composite oxidation tank is 5.56, the alkali ratio is 1.15, the conductivity is 52.5ms / cm, and the temperature is 53.5°C; the free alkali of the second composite oxidation tank is 5.82, the alkali ratio is 1.2, the conductivity is 57.9ms / cm, and the temperature is 50.5°C;

[0070] The total alkali of the second hot water rinse tank is 0.68, the conductivity is 276.8μs / cm, and the temperature is 45.5℃;

[0071] The total alkali of the third hot water rinse tank is 0.08, the conductivity is 24.5ms / cm, and the t...

Embodiment 3

[0074] The free alkali in the first alkali washing tank is 3.18, the alkali ratio is 1.23, the conductivity is 9.2ms / cm, and the temperature is 56.1°C;

[0075] The free alkali in the second alkali washing tank is 3.09, the alkali ratio is 1.11, the conductivity is 8.3ms / cm, and the temperature is 54.8°C;

[0076] The total alkali of the first hot water rinse tank is 1.08, the conductivity is 102.3ms / cm, and the temperature is 54.1°C;

[0077] The free alkali of the first composite oxidation tank is 5.95, the alkali ratio is 1.31, the conductivity is 52.0ms / cm, and the temperature is 55.1°C;

[0078] The free alkali of the second compound oxidation tank is 6.19, the alkali ratio is 1.13, the conductivity is 56.8ms / cm, and the temperature is 50.7°C;

[0079] The total alkali of the second hot water rinse tank is 0.67, the conductivity is 392.8μs / cm, and the temperature is 44.7℃;

[0080] The total alkali of the third hot water rinse tank is 0.11, the conductivity is 23.8μs / cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com