A device and method for positioning a slitting knife to slit multi-width prepreg

A prepreg and slitting knife technology, applied in metal processing and other directions, can solve the problem of limited slitting accuracy, improve efficiency, improve slitting efficiency, and achieve the effect of multi-purpose on one axis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

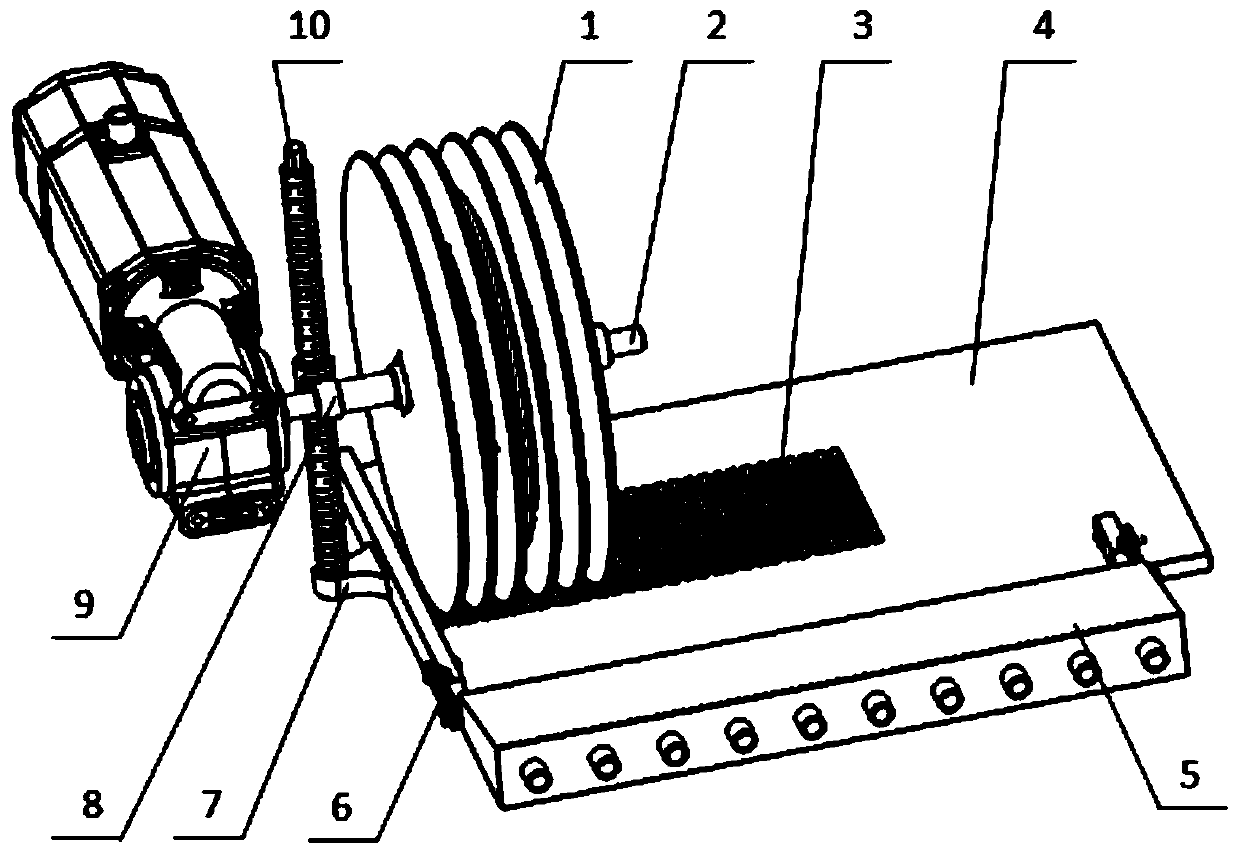

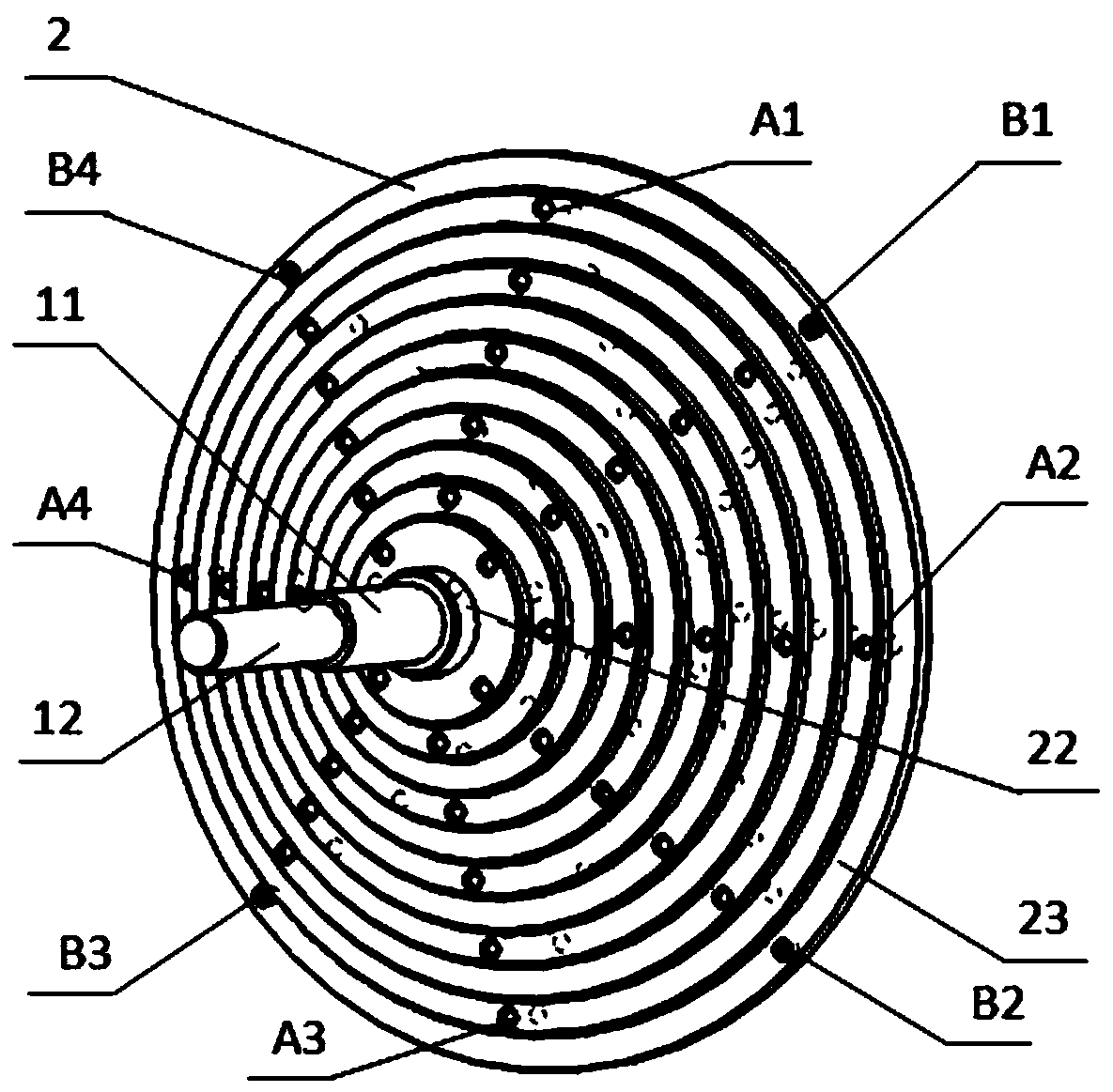

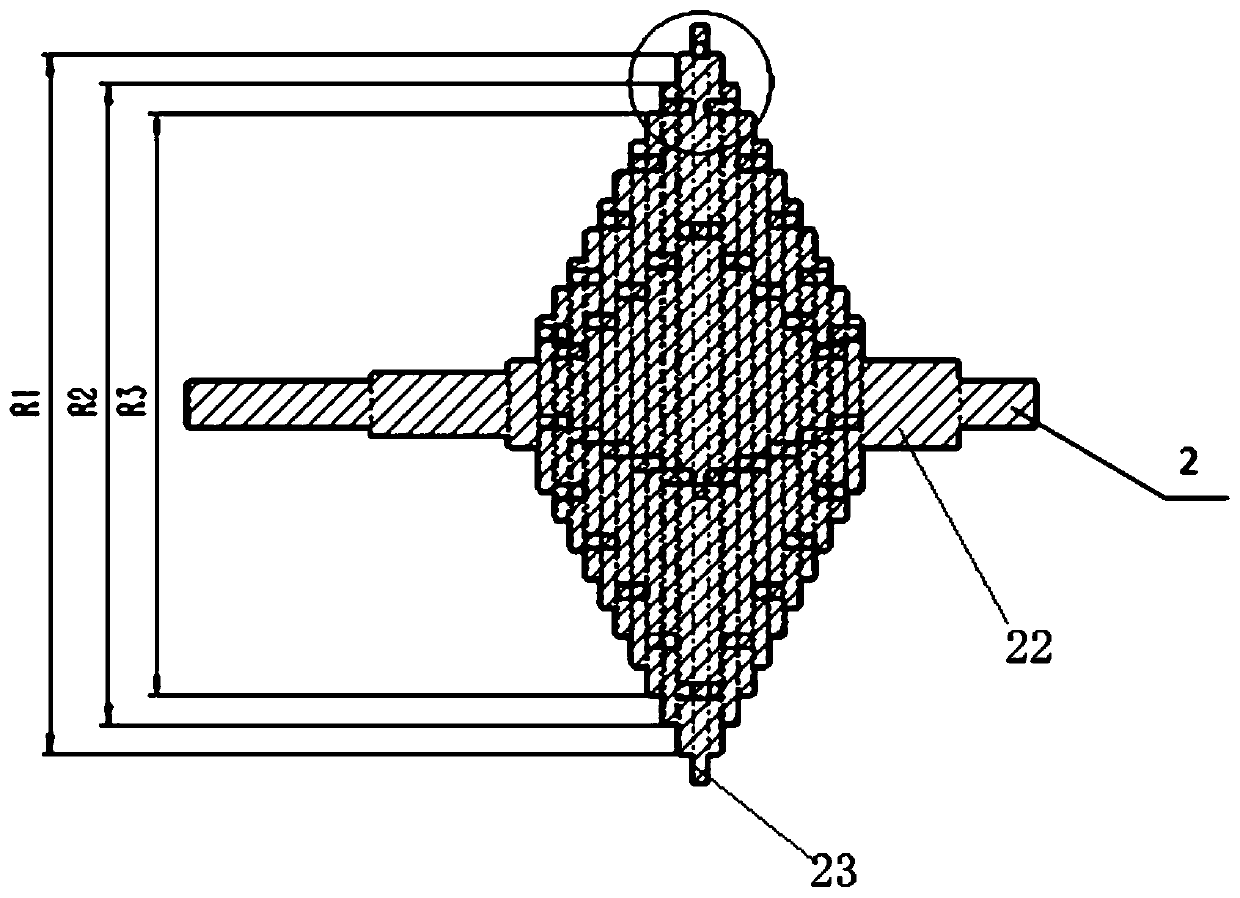

[0036] see figure 1 , the device for slitting multi-width prepreg with high-precision positioning slitting knife of the present invention includes a slitting circular knife 1, a slitting circular knife shaft 2, a lead screw 10, a lead screw connector 8, a driving motor 9, a slitting Table 4 and air-conditioning pipeline 5; wherein, a seat hole 7 is arranged on the side wall at one end of the cutting table 4, and a lead screw 10 is installed in the seat hole 7. Specifically, the end of the lead screw 10 has a segmented optical axis to install a bearing, and is fixed In the seat hole 7 on the side of the cutting table. Leading screw 10 is provided with leading screw connector 8, and some cutting round cutter shafts 2 are sheathed with some cutting round knives 1, and one end of cutting round cutter shaft 2 passes through leading screw connector 8 and links to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com