Ceramic part applied to aerospace field and preparation method of ceramic part

A technology in the field of ceramic parts, applied in the field of ceramic parts and their preparation, can solve the problems of reducing the weight of birds, accelerating the development of cracks, and breaking and damaging ceramic parts, so as to reduce its own weight, reduce welding defects, and not easily break Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

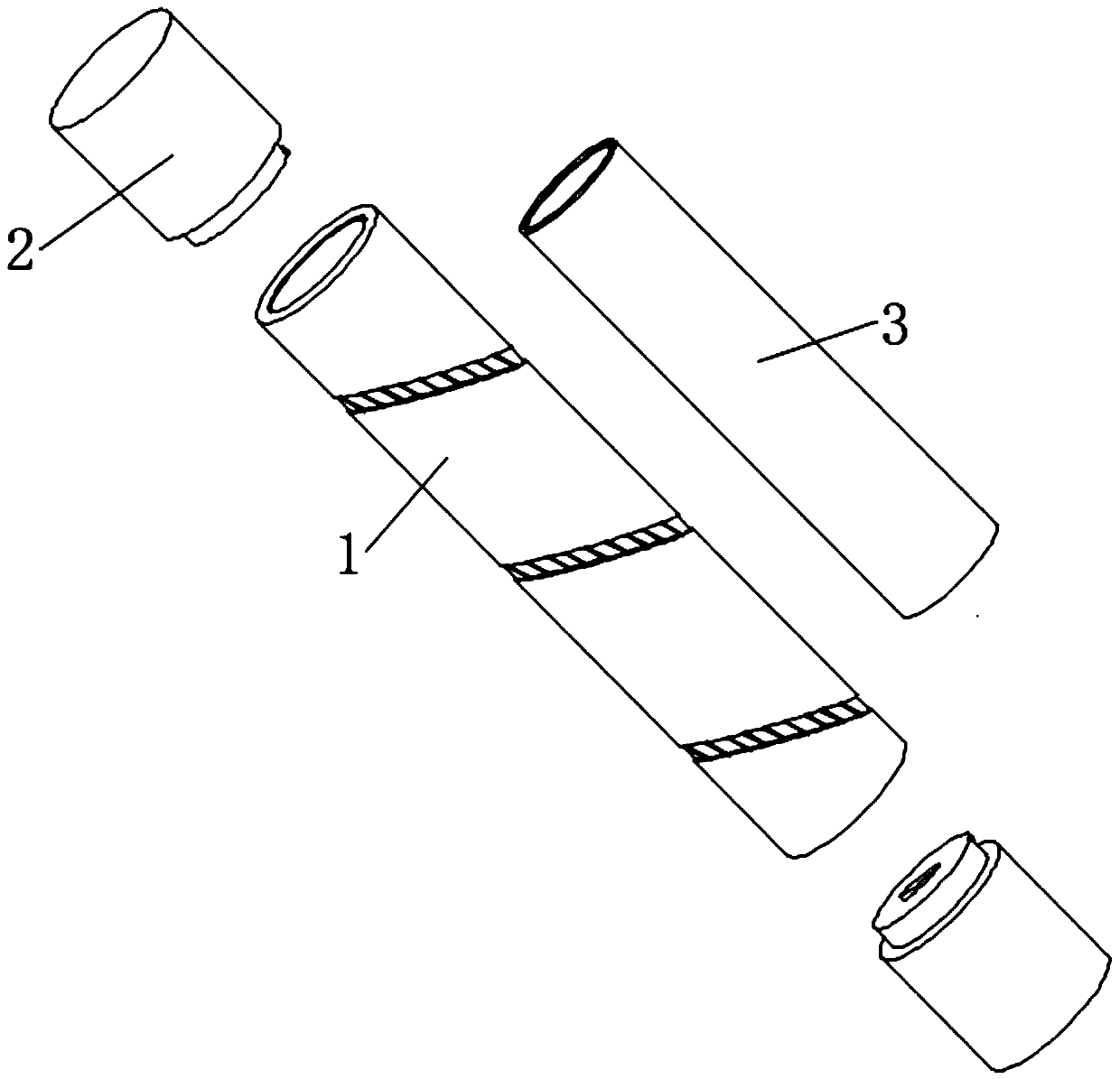

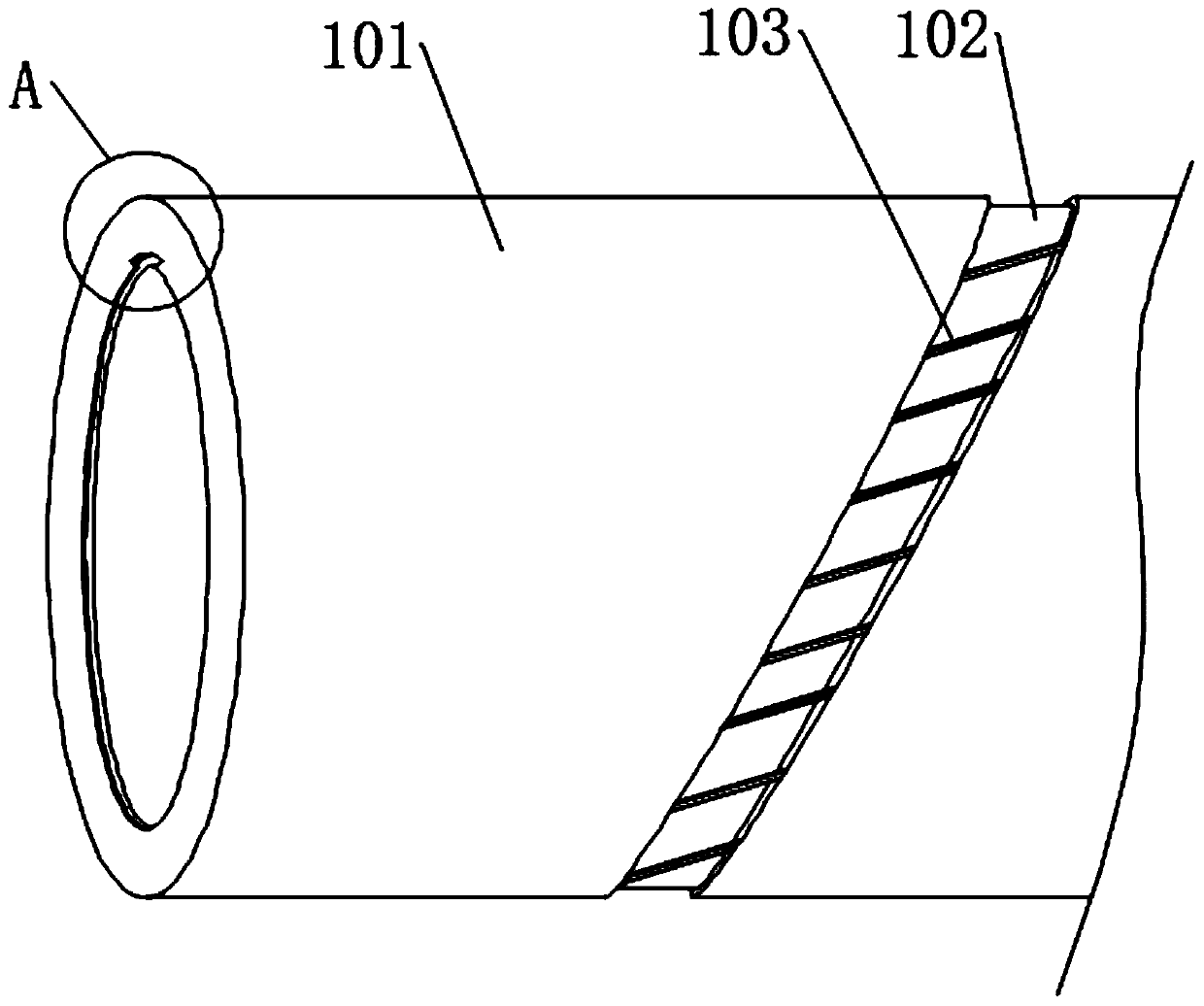

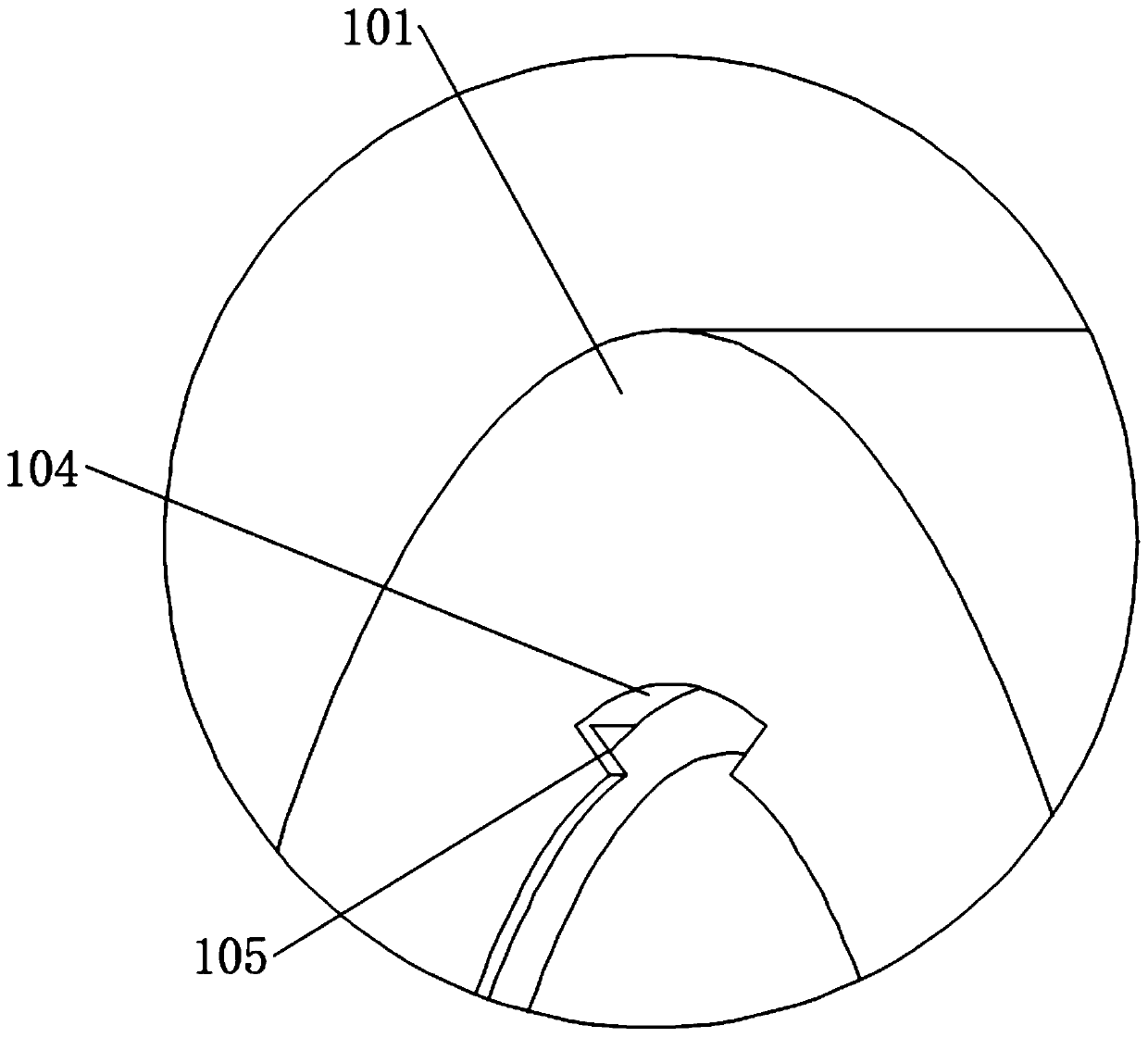

[0042] See Figure 1-5 , A ceramic part applied in the aerospace field and a preparation method thereof, comprising a central shaft tube 1, a central shaft tube inner core 3 is inserted into the central shaft tube 1, and a pair of connections are fixedly connected at both ends of the central shaft tube 1 Part 2, wherein the bottom bracket tube 1 is the main body of the ceramic part, and the connecting piece 2 is the sealed end of the bottom bracket tube 1. At the same time, the connecting piece 2 is also the connecting end of the bottom bracket tube 1, and the bottom bracket tube 1 can pass through the connecting piece. 2 is connected to an external object. The connector 2 includes a sealing head 201, and one end of the sealing head 201 close to the bottom bracket tube 1 is fixedly connected with a convex post 202 that matches the inner wall of the bottom bracket tube 1. A positioning wedge 204 is fixedly connected to the side wall, the sealing head 201 is the sealing end, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com