Graphene composite rare earth modification hypo eutectic Al-Si-Mg casting alloy and preparing method thereof

A graphene composite and rare earth modification technology, applied in the field of cast aluminum alloy, can solve the problems of poor plasticity and low mechanical properties of the alloy, and achieve the effect of promoting homogenization, uniform microstructure and ensuring constant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

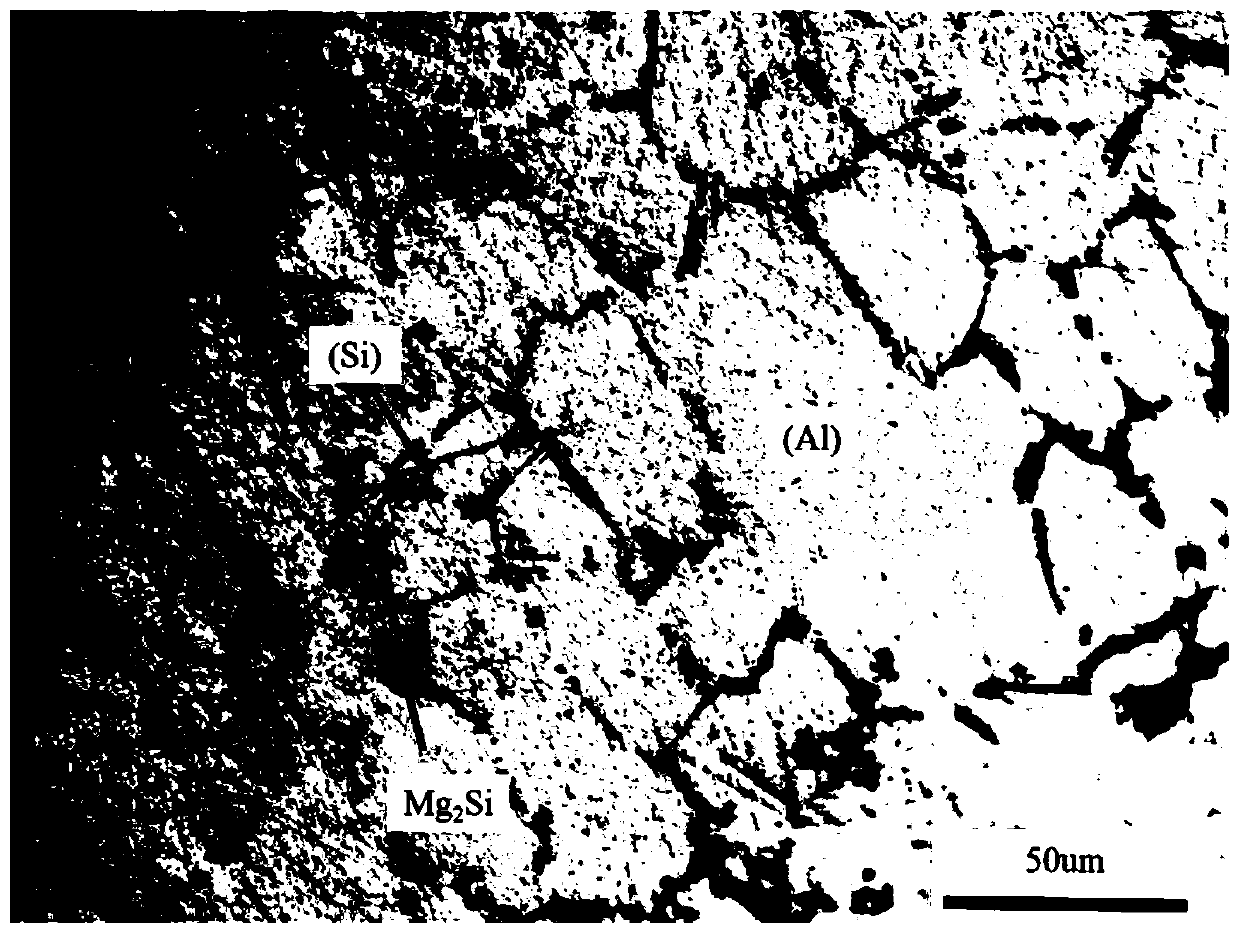

Embodiment 1

[0059] This embodiment intends to prepare a graphene composite rare earth metamorphic hypoeutectic Al-Si-Mg casting alloy, its chemical composition is: Si5.00wt.%, Mg 0.50wt.%, Ce 0.41wt.%, Ti 0.10wt .%, Fe 0.12wt.%, Cu0.10wt.%, Mn 0.03wt.%, Cr 0.03wt.%, Ni 0.03wt.%, Zn 0.20wt.%, Sn 0.10wt.%, Zr0.05wt.% , Be 0.05wt.%, Pb 0.05wt.%, Graphene 0.005wt.%; other unspecified impurity elements: each ≤0.02wt.%, total ≤0.10wt.%, the balance is Al.

[0060] The specific preparation method is as follows:

[0061] (1) Weigh the raw materials of each component according to the ratio of alloy elements: aluminum particles, Si particles, Mg powder, Ce powder, Ti powder, Fe powder, Cu powder, Mn powder, Cr powder, Ni powder, Zn powder, Sn powder , Zr powder, Be powder, Pb powder, graphene;

[0062] (2) Spread the weighed graphene on the aluminum foil, titrate a small amount of high-purity alcohol to fully dissolve the graphene in the alcohol, add Si particles, stir evenly, fold the aluminum f...

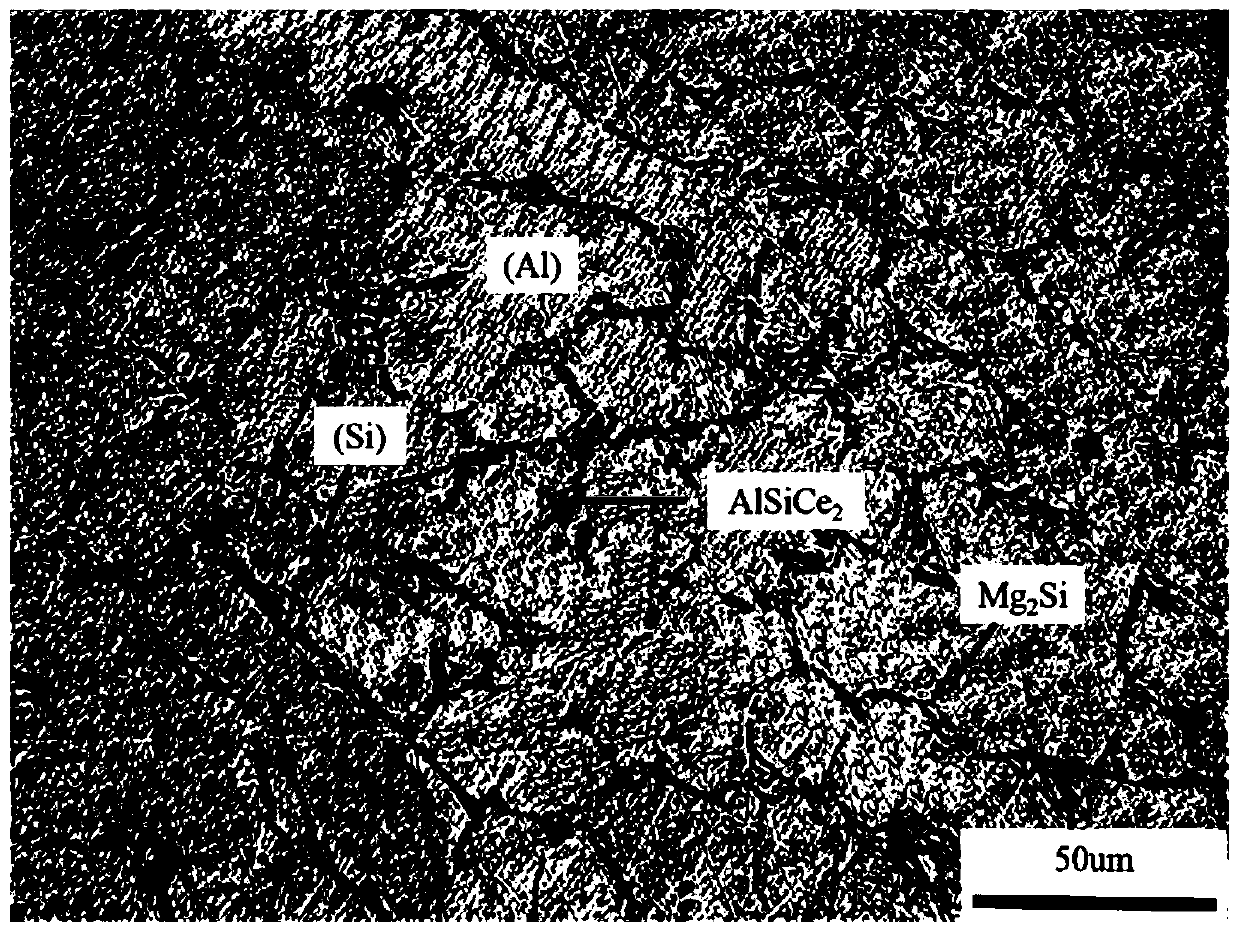

Embodiment 2

[0070] This embodiment intends to prepare a graphene composite rare earth metamorphic hypoeutectic Al-Si-Mg casting alloy, its chemical composition is: Si 7.00wt.%, Mg 0.50wt.%, Ce 0.61wt.%, Ti 0.10wt .%, Fe 0.12wt.%, Cu0.10wt.%, Mn 0.03wt.%, Cr 0.03wt.%, Ni 0.03wt.%, Zn 0.20wt.%, Sn 0.10wt.%, Zr0.05wt.% , Be 0.05wt.%, Pb 0.05wt.%, Graphene 0.005wt.%; other unspecified impurity elements: each ≤0.02wt.%, total ≤0.10wt.%, the balance is Al.

[0071] The specific preparation method is as follows:

[0072] (1) Weigh the raw materials of each component according to the ratio of alloy elements: aluminum particles, Si particles, Mg powder, Ce powder, Ti powder, Fe powder, Cu powder, Mn powder, Cr powder, Ni powder, Zn powder, Sn powder , Zr powder, Be powder, Pb powder, graphene;

[0073] (2) Spread the weighed graphene on the aluminum foil, titrate a small amount of high-purity alcohol to fully dissolve the graphene in the alcohol, add Si particles, stir evenly, fold the aluminum ...

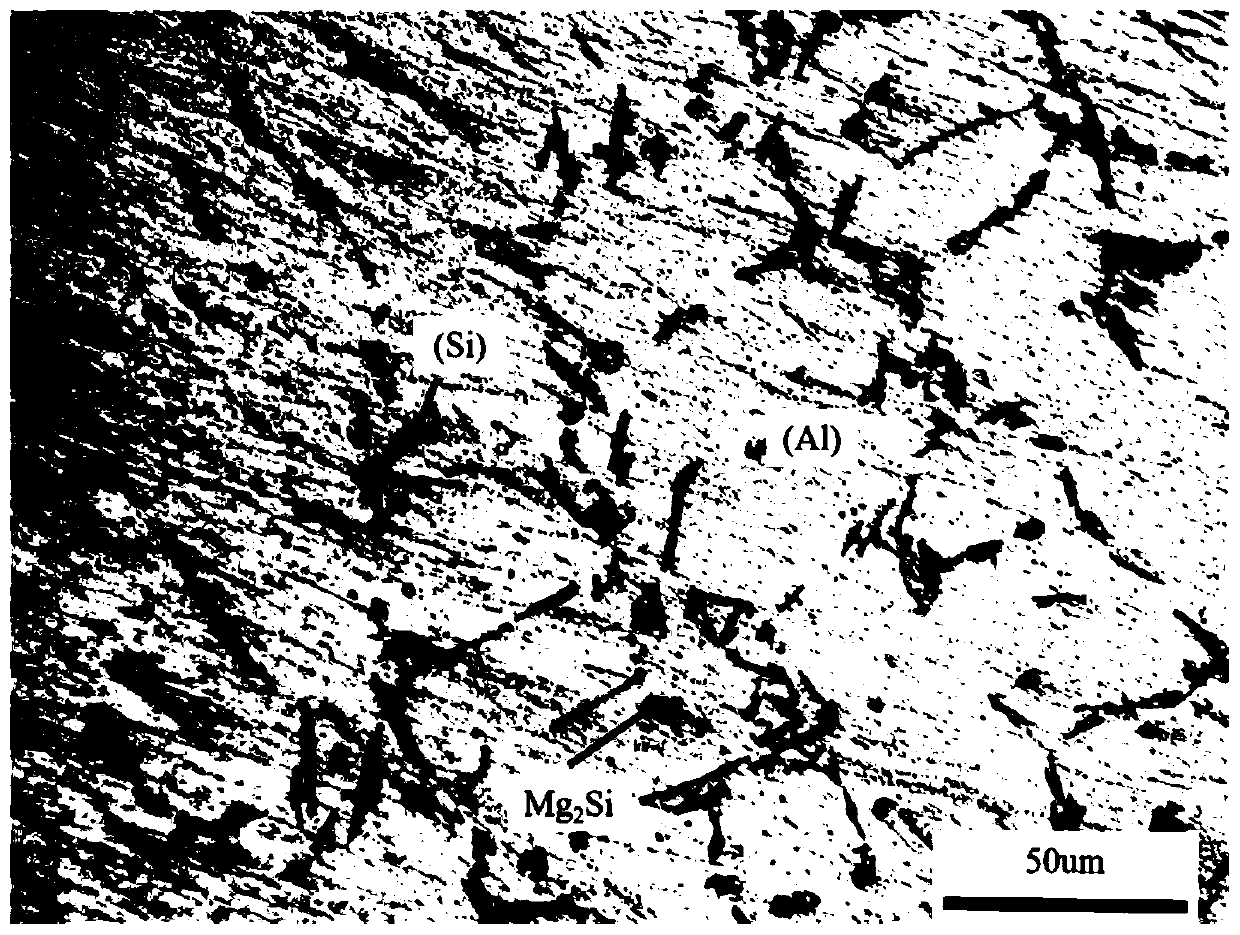

Embodiment 3

[0081] This embodiment intends to prepare a graphene composite rare earth metamorphic hypoeutectic Al-Si-Mg casting alloy, its chemical composition is: Si 7.00wt.%, Mg 0.60wt.%, Ce 0.83wt.%, Ti 0.10wt .%, Fe 0.12wt.%, Cu0.10wt.%, Mn 0.03wt.%, Cr 0.03wt.%, Ni 0.03wt.%, Zn 0.20wt.%, Sn 0.10wt.%, Zr0.05wt.% , Be 0.05wt.%, Pb 0.05wt.%, Graphene 0.005wt.%; other unspecified impurity elements: each ≤0.02wt.%, total ≤0.10wt.%, the balance is Al.

[0082] The specific preparation method is as follows:

[0083] (1) Weigh the raw materials of each component according to the ratio of alloy elements: aluminum particles, Si particles, Mg powder, Ce powder, Ti powder, Fe powder, Cu powder, Mn powder, Cr powder, Ni powder, Zn powder, Sn powder , Zr powder, Be powder, Pb powder, graphene;

[0084] (2) Spread the weighed graphene on the aluminum foil, titrate a small amount of high-purity alcohol to fully dissolve the graphene in the alcohol, add Si particles, stir evenly, fold the aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com