LNG receiving station energy saving new process and energy saving system

An energy-saving system and receiving station technology, applied in the direction of steam engine devices, gas turbine devices, machines/engines, etc., can solve the problems of power consumption and cold energy throwing away, so as to save power consumption, save maintenance costs, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

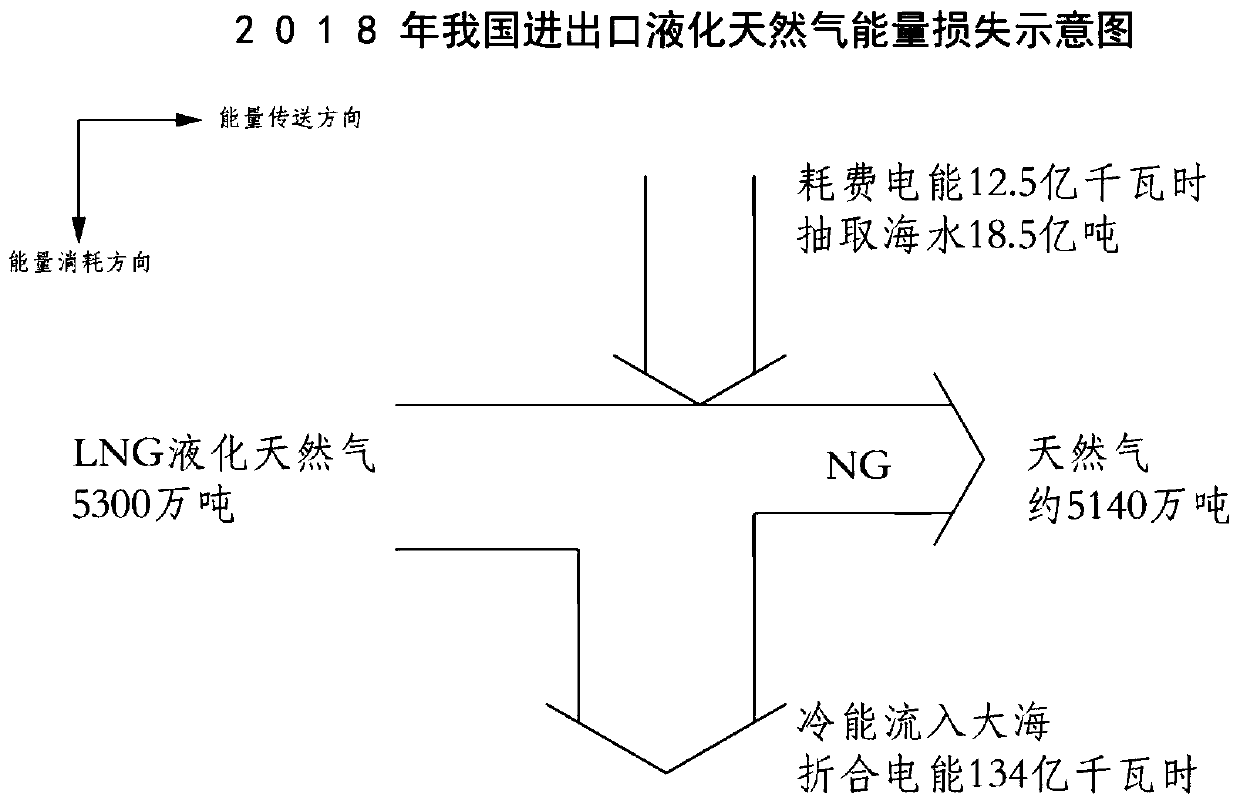

Problems solved by technology

Method used

Image

Examples

example

[0116] Taking Huaying Chaozhou LNG receiving station as an example,

[0117]The receiving capacity of the station is 6 million tons of LNG per year. The receiving station is designed with 7 LNG storage tanks, each with 200,000 cubic meters.

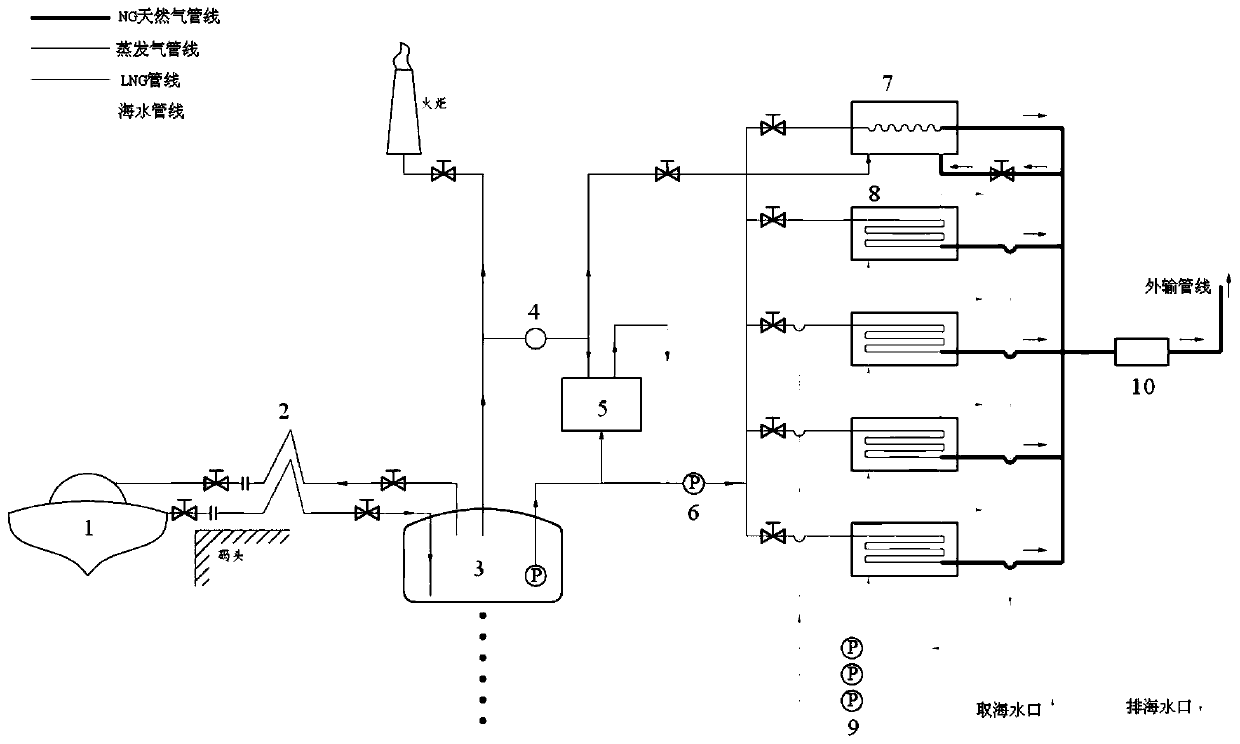

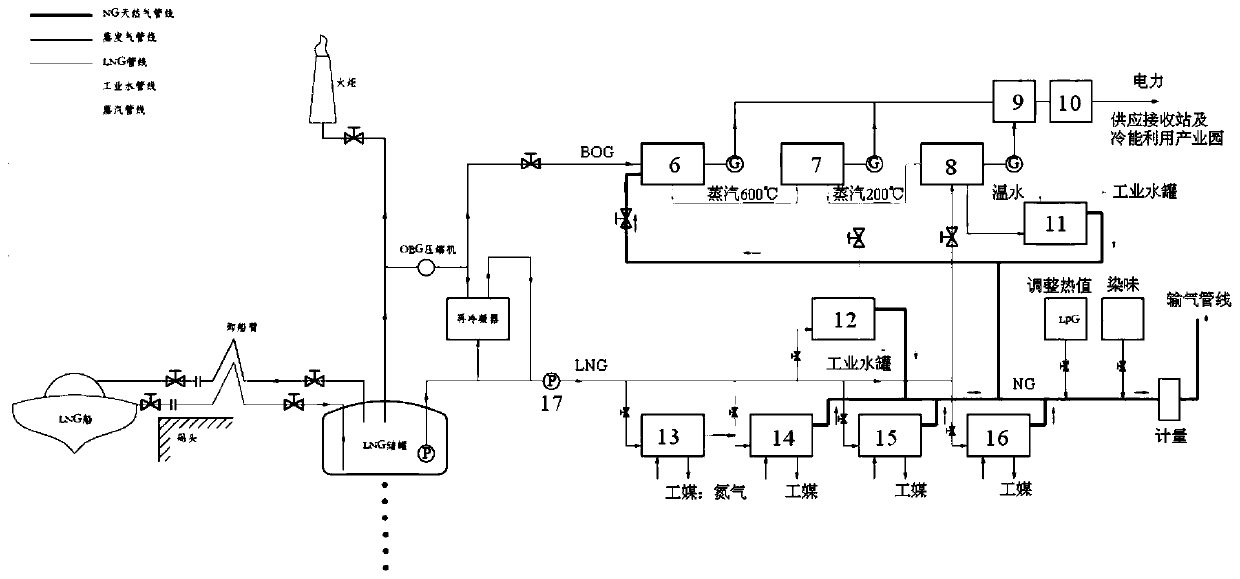

[0118] The pump in the tank pumps LNG out of the tank, and the LNG is transported to the gasification area through the high-pressure pump, and then enters the intermediate gasifier IFV, where it exchanges heat with the intermediate medium, (the intermediate medium can be selected according to the specific needs of the cold energy utilization project ) heat exchange makes the LNG gasify, after being collected, the calorific value is adjusted, the odor is dyed, and the metering is carried out to the high-pressure pipeline network for supply to users. The IFV transfers the cold energy to the industrial projects of cold energy utilization through the intermediate medium for utilization.

[0119] Part of the LNG passes through the cooler 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com