Detecting system for rapid sealing of concentration sensor and method thereof

A technology of concentration sensor and seal detection, which is applied in liquid tightness measurement using liquid/vacuum degree, and detects the appearance of fluid at the leakage point, instruments, etc. Test time-consuming and other problems, to achieve the effect of eliminating hidden dangers in production safety, simple calculation process, and save test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

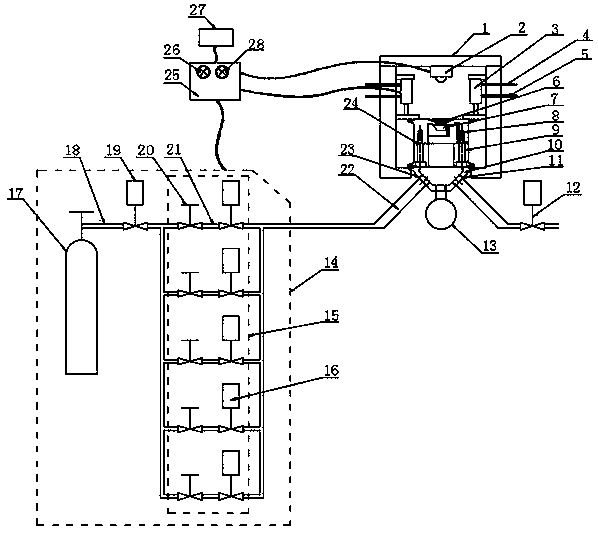

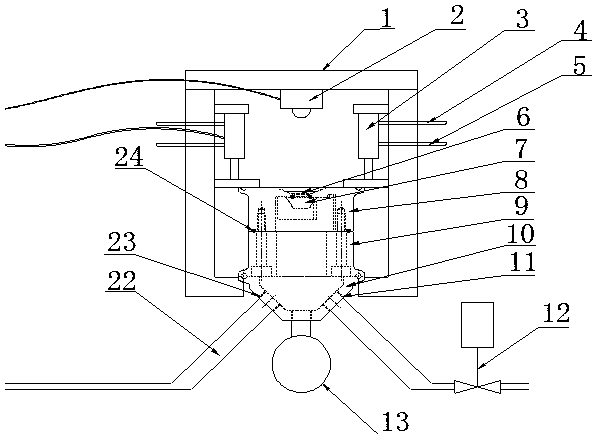

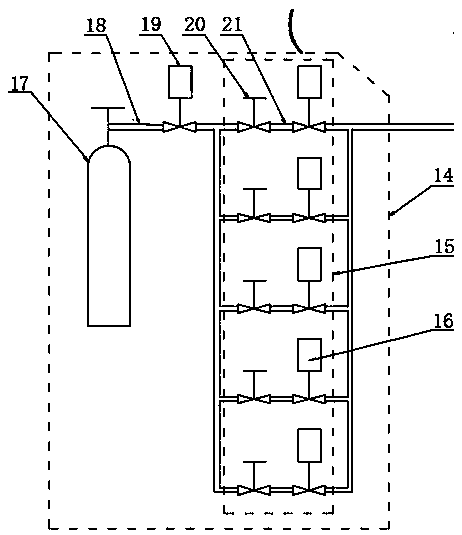

[0040] Such as Figure 1-Figure 5 shown ( Figure 5is the test prism image captured by the camera 2, water is used as the test liquid in this embodiment), a fast sealing detection system and method for the concentration sensor, including the prism lens case of the concentration sensor to be measured arranged in the measurement bracket 1 body 8, an optical sensing prism 7 is sealed at the upper end of the prism lens housing 8, and the prism lens housing 8 and the optical sensing prism 7 jointly form a liquid-carrying port for holding the test liquid 6, the prism lens housing 8 Below is connected with an air pressure chamber 10, is provided with a transition chamber 9 between the air pressure chamber 10 and the prism lens housing 8, is all provided with sealing ring 24 between the transition chamber 9 and the prism lens housing 8, the air pressure chamber 10, the air pressure chamber 10 is provided with an air inlet 23 and an exhaust port 11, the air pressure chamber exhaust po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com