Powder brushing machine

A powder brushing machine and technology for brushing powder are applied in the directions of removing smoke and dust, cleaning methods and utensils, and cleaning methods using tools, etc., which can solve problems such as low efficiency, affect the health of workers, damage semi-finished products, etc., and achieve a clean working environment. Conducive to the effect of daily inspection and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

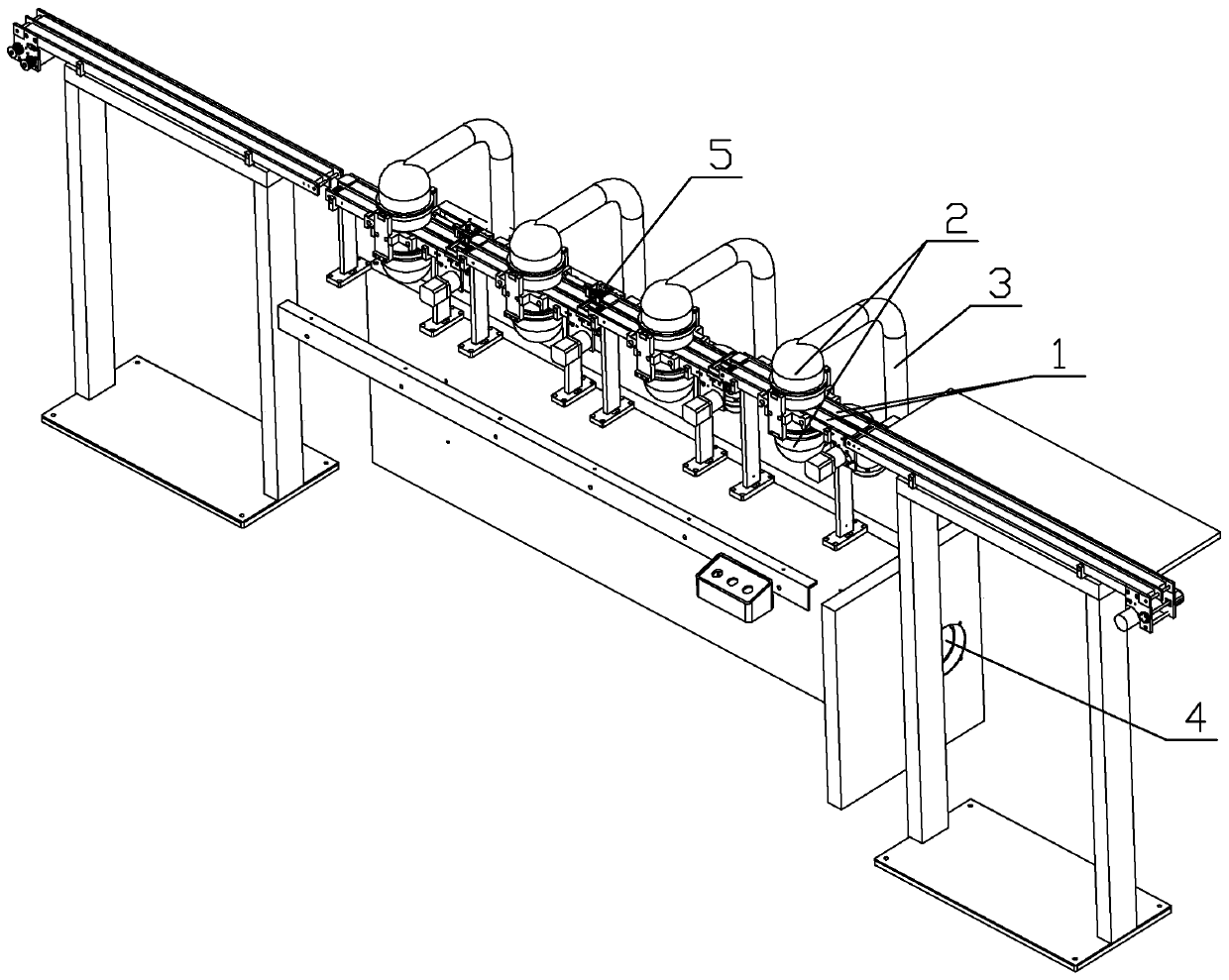

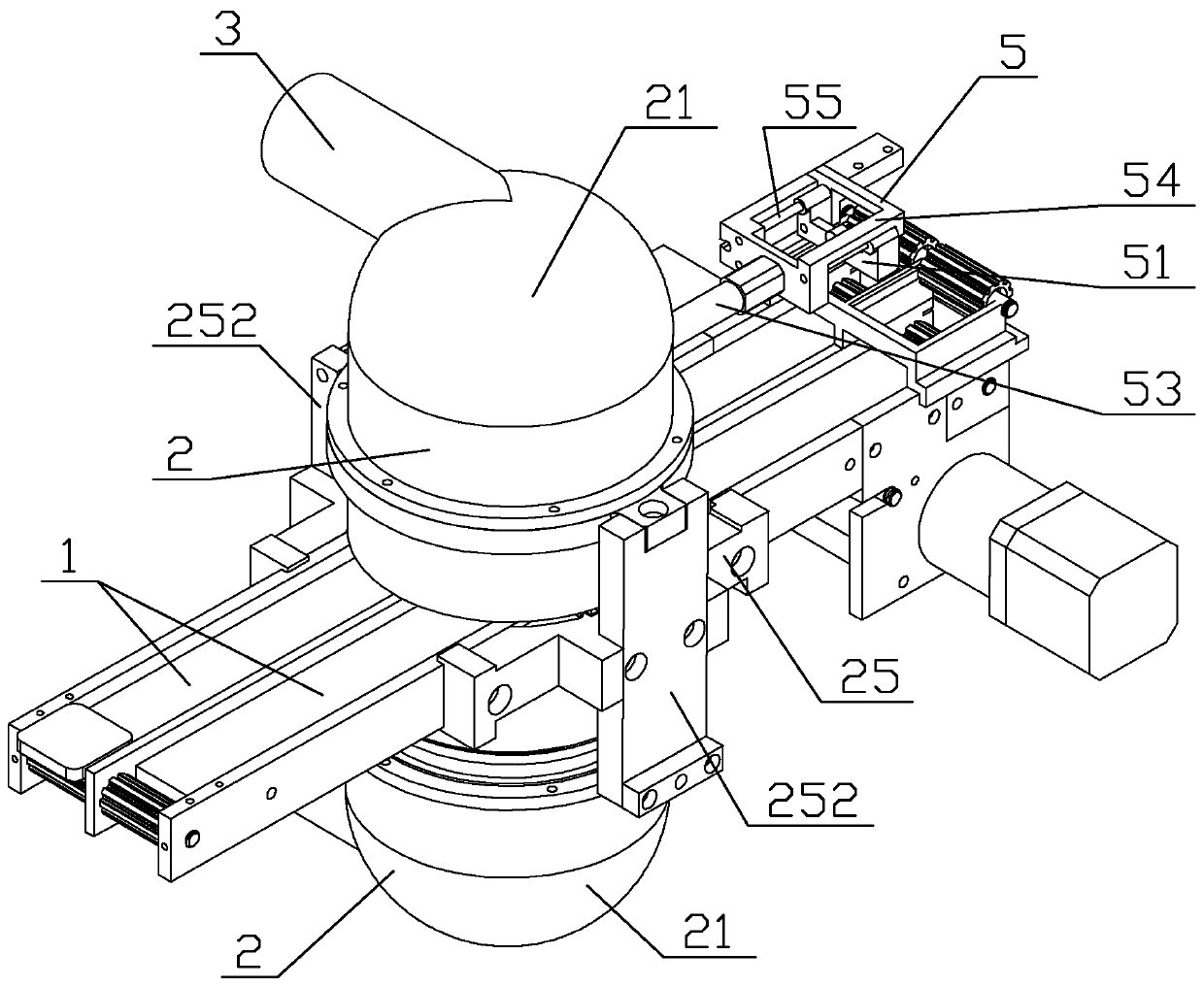

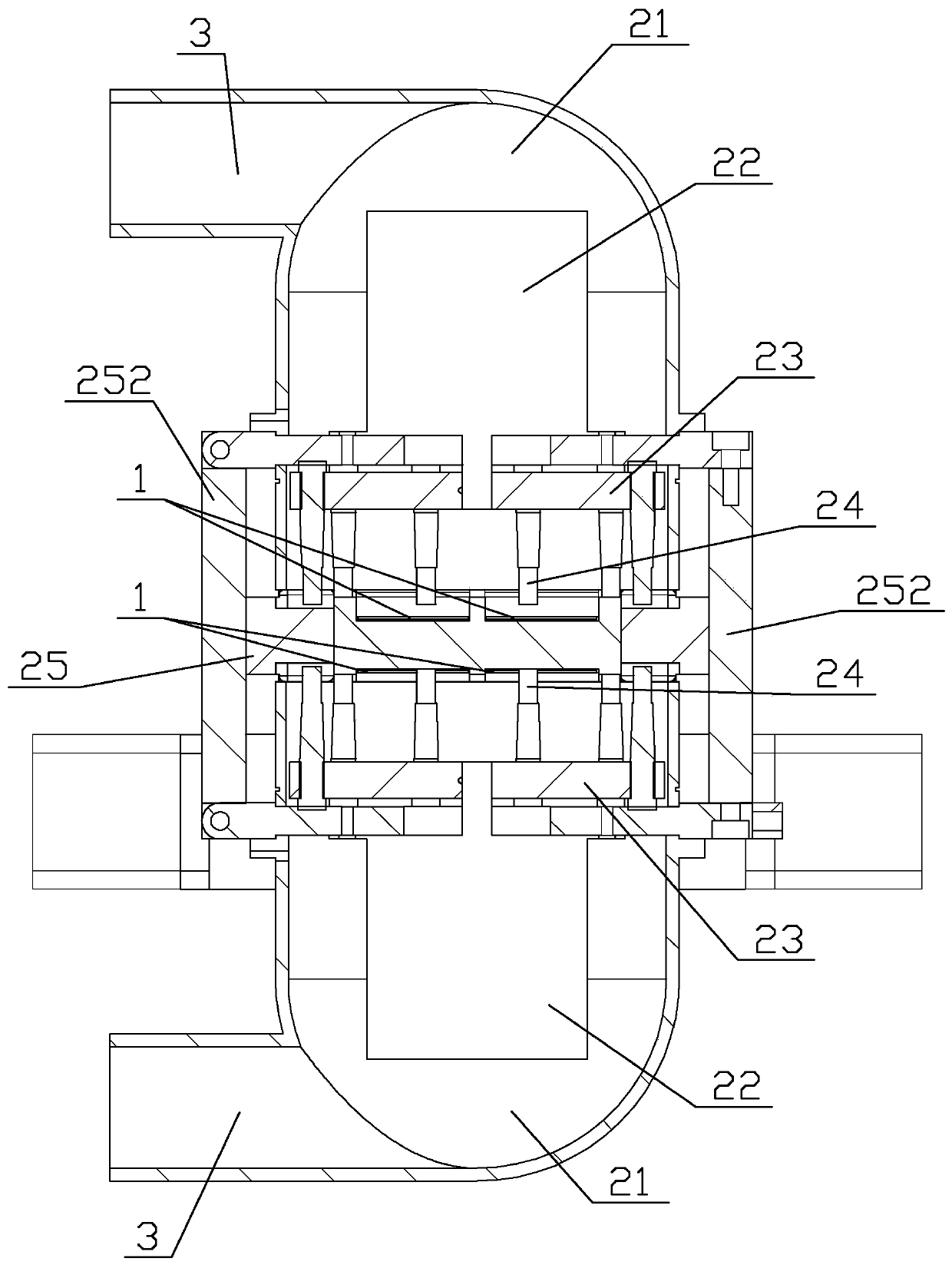

[0022] Such as figure 1 , 2 , 3, 4, 5, and 6 show a specific embodiment of the powder brushing machine of the present invention. This embodiment includes a conveyor belt 1 for conveying semi-finished ceramic sheets arranged in a stepped manner before and after the even-numbered sections, and a cleaning device arranged above the conveyor belt 1 for brushing and cleaning the semi-finished ceramic sheets on the conveyor belt 1. Mechanism 2, the dust suction pipe 3 connected to the cleaning mechanism 2 and externally connected to the dust removal mechanism, and the turning mechanism 5 for turning the semi-finished ceramic sheet between the conveyor belts 1 at both ends, when the semi-finished ceramic sheet When conveying on the conveyor belt 1, the cleaning mechanism 2 performs powder coating on the conveyor belt 1 of the odd segment, and the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com