Special hydraulic hoisting casting device for steel mill metallurgy

A metallurgical and hydraulic technology, applied in hoisting devices, hoisting equipment braking devices, cranes, etc., can solve problems such as the lack of stability of the ladle, avoid the risk of molten steel overflow, protect equipment damage, and avoid splashing out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

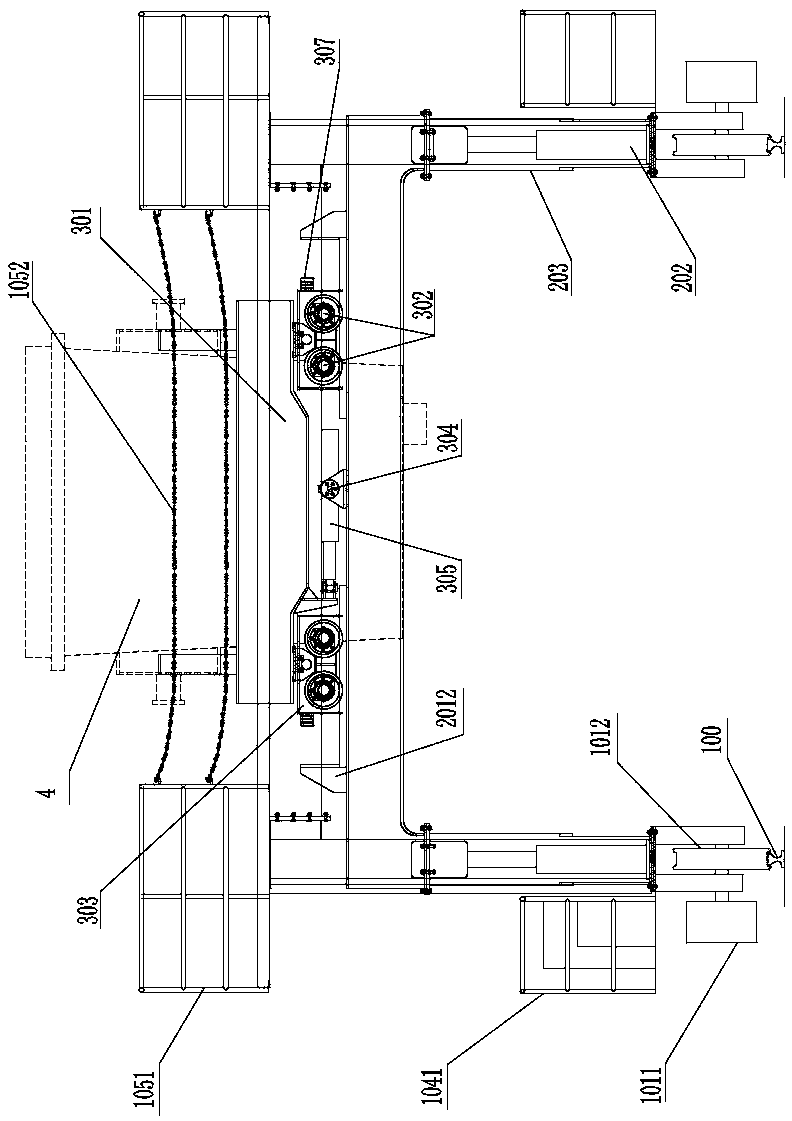

[0029] The present invention will be further described below in conjunction with the accompanying drawings. In this embodiment, the direction of the first track is horizontal to represent the Y-axis direction in the space coordinate system, and the direction of the second track is vertical to represent the space In the X-axis direction in the coordinate system, the direction of the third track is vertical, so as to represent the Z-axis direction in the space coordinate system.

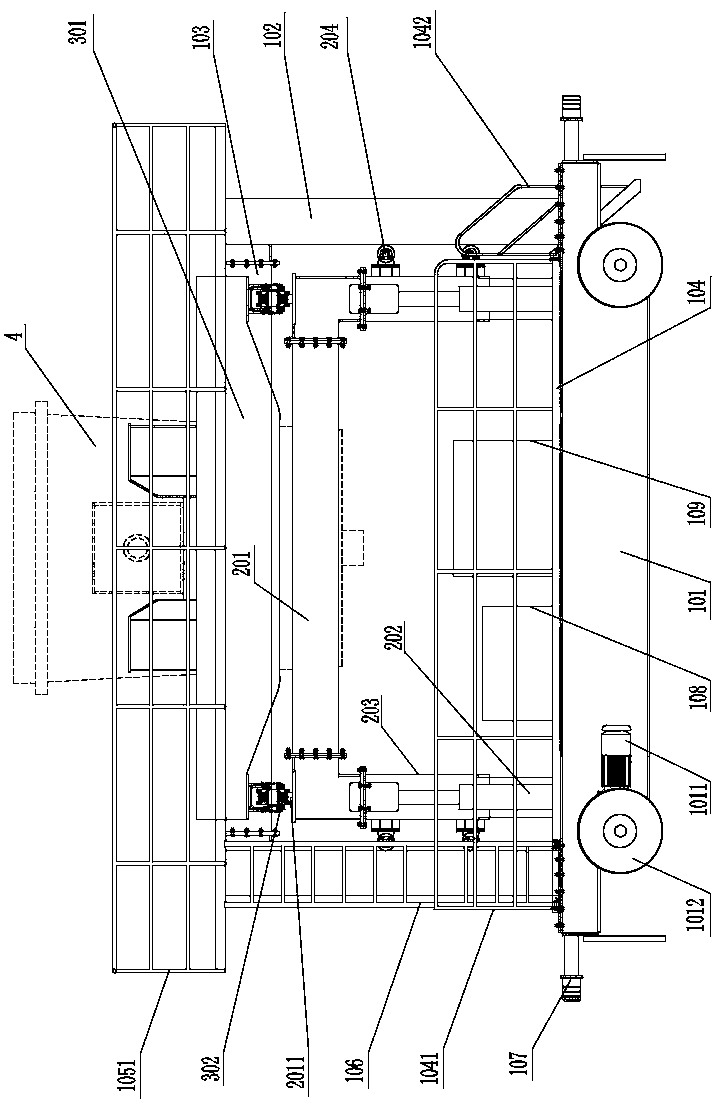

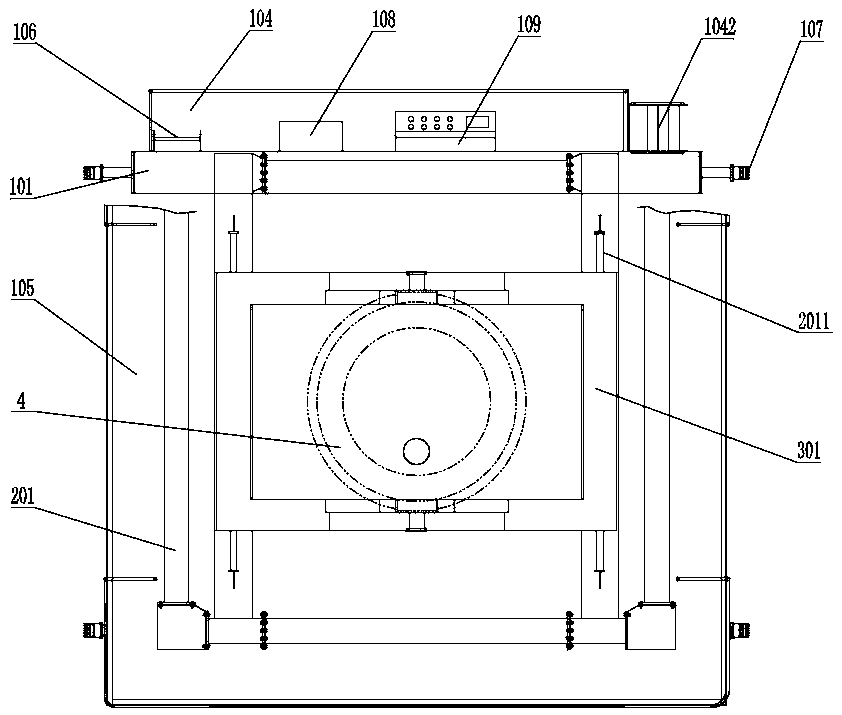

[0030] Such as Figure 1-Figure 4 As shown, the present invention provides a special hydraulic lifting and casting device for steel plant metallurgy, hereinafter referred to as the casting device, including a hydraulic pump station 108, a console 109, a cart operating mechanism, a lifting mechanism, a trolley operating mechanism and two parallel And the first track 100 that is arranged horizontally, the cart running mechanism includes two walking beams 101, the bottom of the walking beam 101 is rotatab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com