Magnesium pack steel wire main cable steel tendon and manufacturing method thereof

A manufacturing method and steel wire-wrapped technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of defective anchorage safety hazards, insufficient detection, etc., and achieve the effects of ensuring quality, prolonging service life, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following clearly and completely describes the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them.

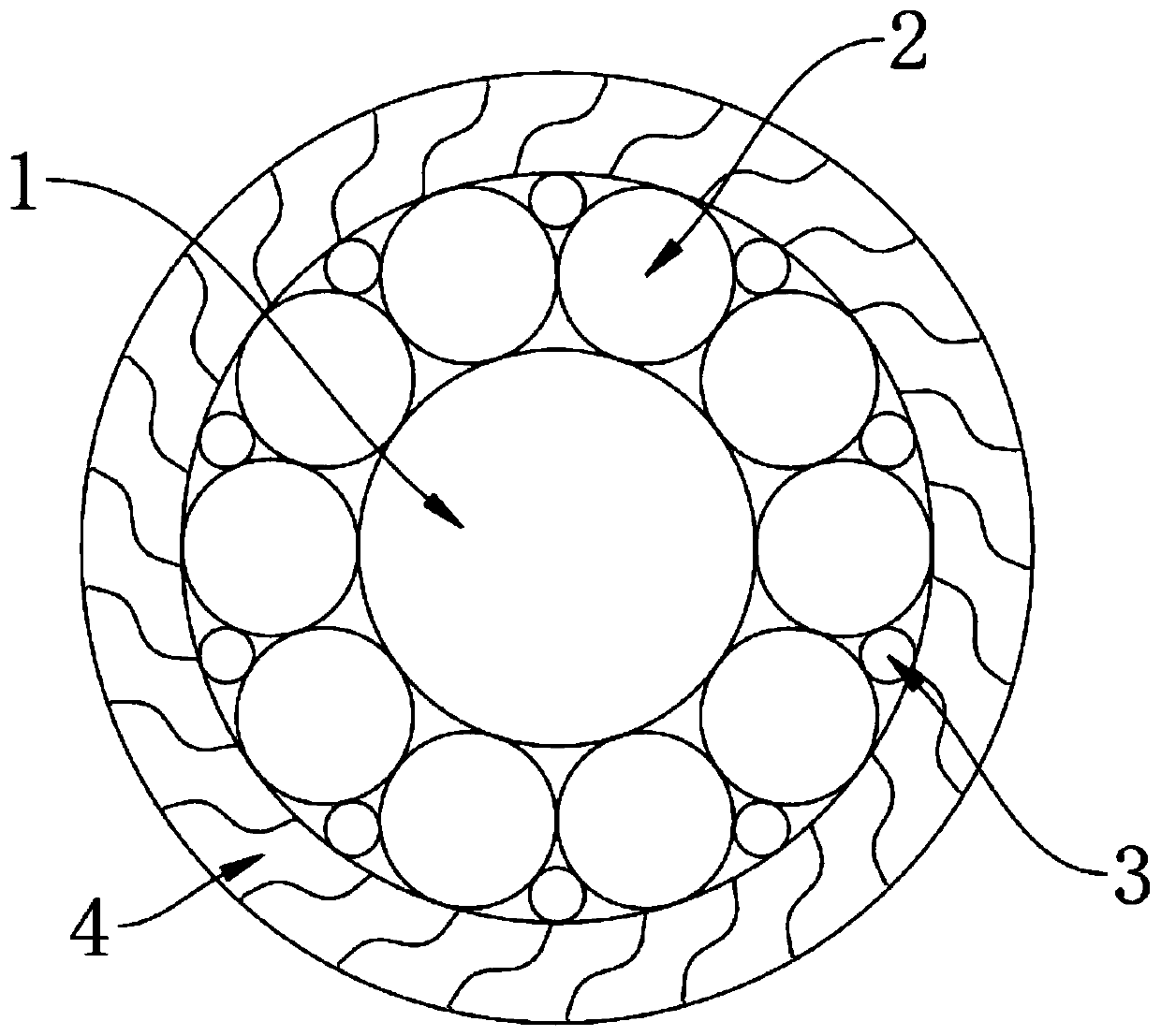

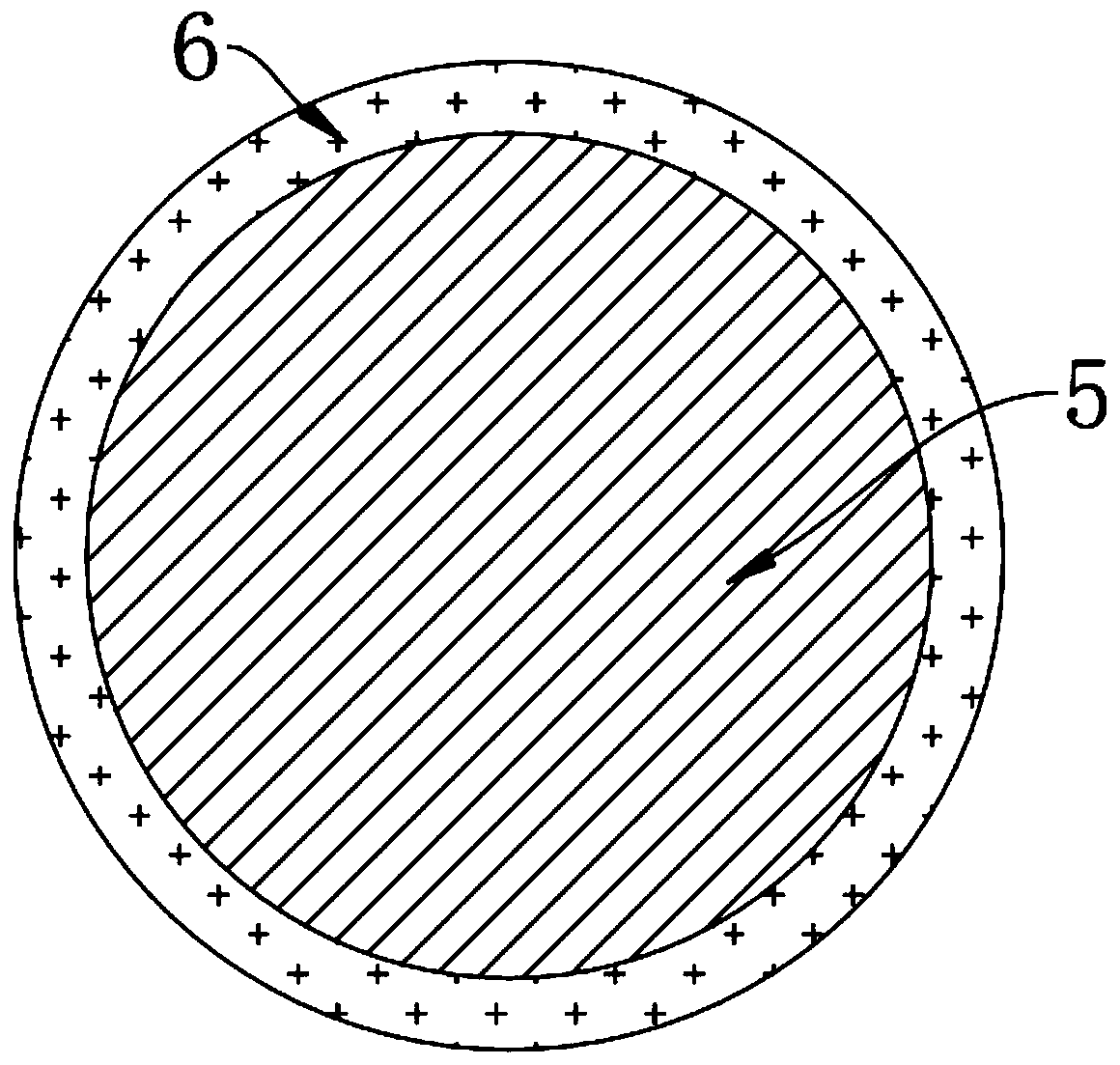

[0039] Such as figure 1 and figure 2 As shown, the main cable strand of magnesium-clad steel wire includes a main steel wire 1, which is characterized in that: the outside of the main steel wire 1 is provided with wrapped steel wires 2, and there are ten wrapped steel wires 2, and the outer parts of the ten wrapped steel wires 2 The surface is tangent to the outer surface of the main steel wire 1, and the fastening steel wire 3 is arranged between the adjacent wrapped steel wires 2, and the outer surface of the fastened steel wire 3 is tangent to the outer surface of the adjacent wrapped steel wire 2, and the wrapped steel wire 2 And the outside of the fastening steel wire 3 is provided with a protective steel bar 4, and several protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com