Integral Hoisting Method of Large-span Spherical Grid Frame

An integral hoisting, large-span technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of low work efficiency, inability to guarantee project quality and safe production, etc., to ensure quality, reduce the amount of scaffolding, and facilitate The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

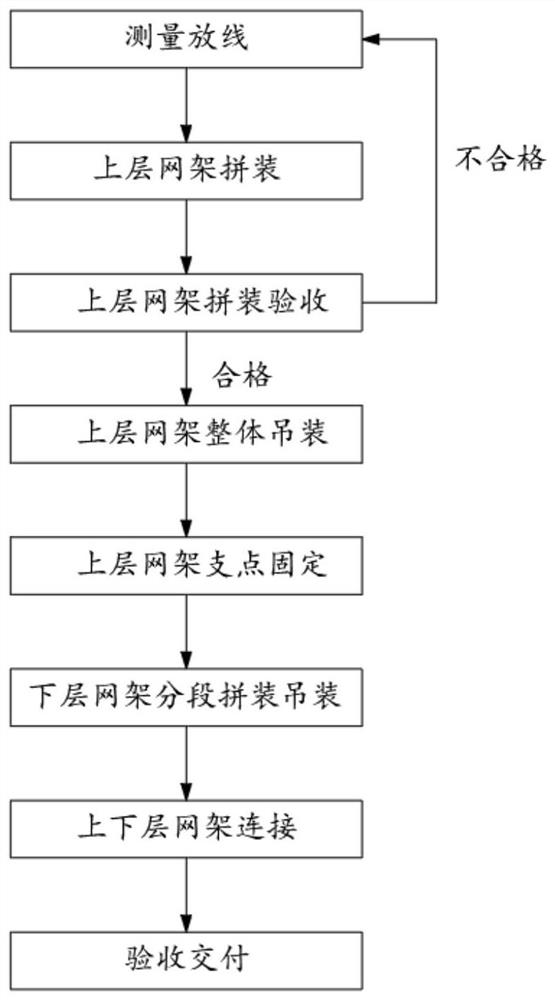

Method used

Image

Examples

Embodiment 1

[0047] The main structure of this embodiment is located between the 1A# building and the 1B# building of the headquarters base in the South Sichuan Port Area of the Sichuan Free Trade Zone, and is mainly composed of two parts: a flat surface grid and a suspended grid. The structure form is: orthogonal and orthogonal quadrangular pyramid planar grid, and the node type is solder ball. The support form is: multi-point support of the lower chord. The entire network frame is supported by 8 supports, and the support distance is 64.55m in the length direction and 6.6m in the width direction. The steel grid installation height is 42.4m.

[0048] The steel grid frame is a special shape, with a maximum length of 64.55m, a maximum width of 17.6m, and a maximum height of 13.65m. The actual coverage area is 890㎡. It is a long-span space structure with a total weight of about 75 tons. The support method is multi-point support on the lower chord, and the sagittal height of the upper grid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com