Dual pipe constraint type self-resetting buckling-restrained brace device based on belleville springs

A technology of anti-buckling support and butterfly spring, which is applied in the direction of earthquake resistance, building type, building maintenance, etc., can solve the problems of unstable support performance, large support weight, difference between support performance and design performance, etc., to ensure hysteresis in tension and compression The curve, the support force performance is stable, and the effect of being convenient for hoisting on the construction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

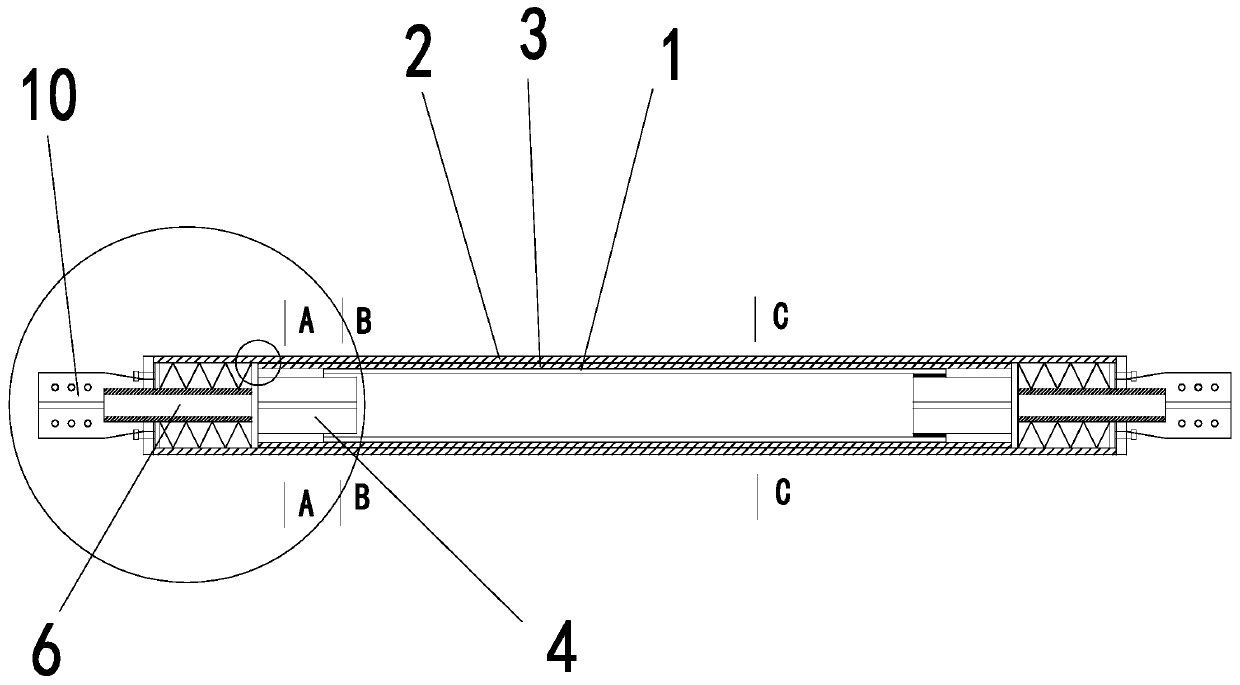

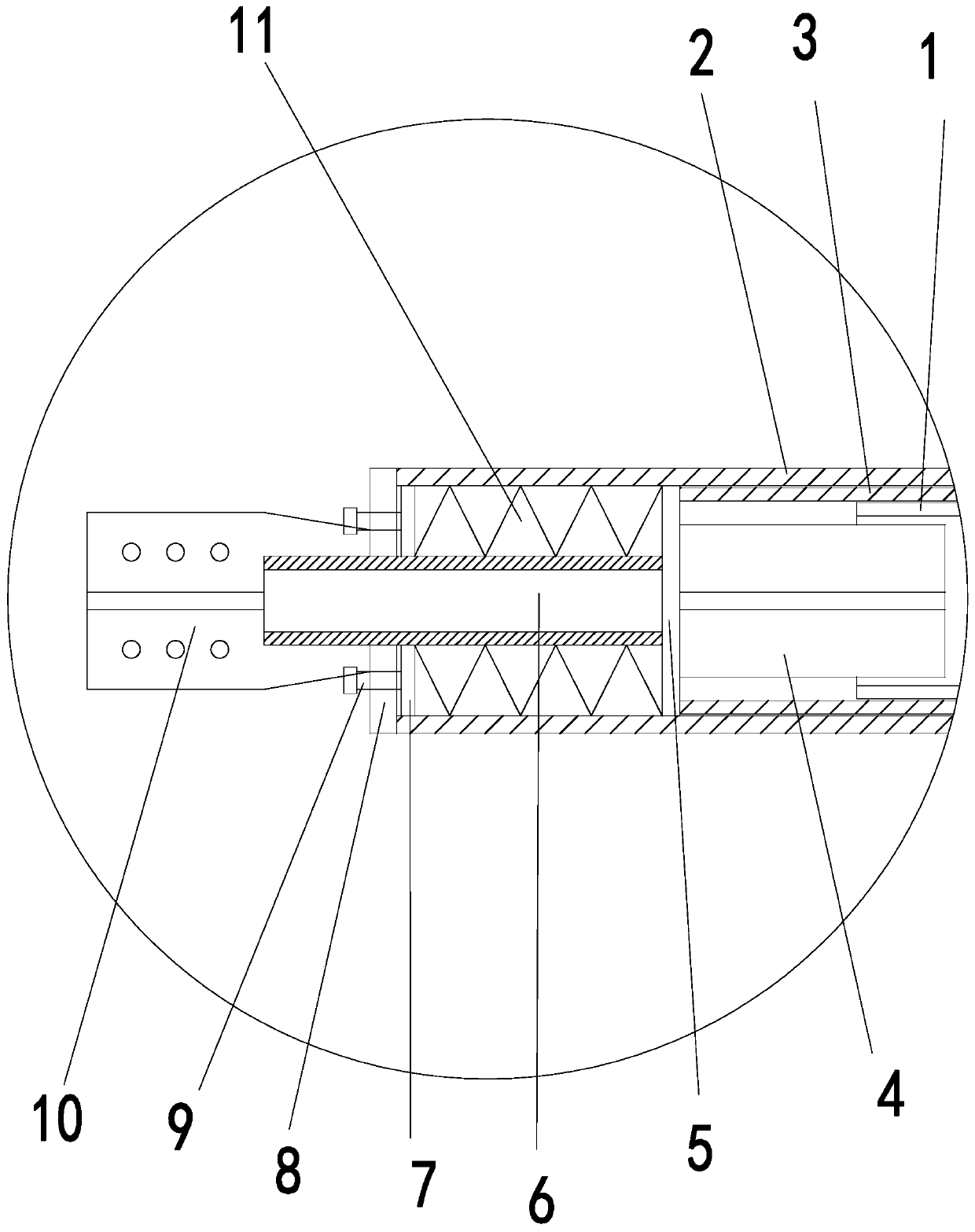

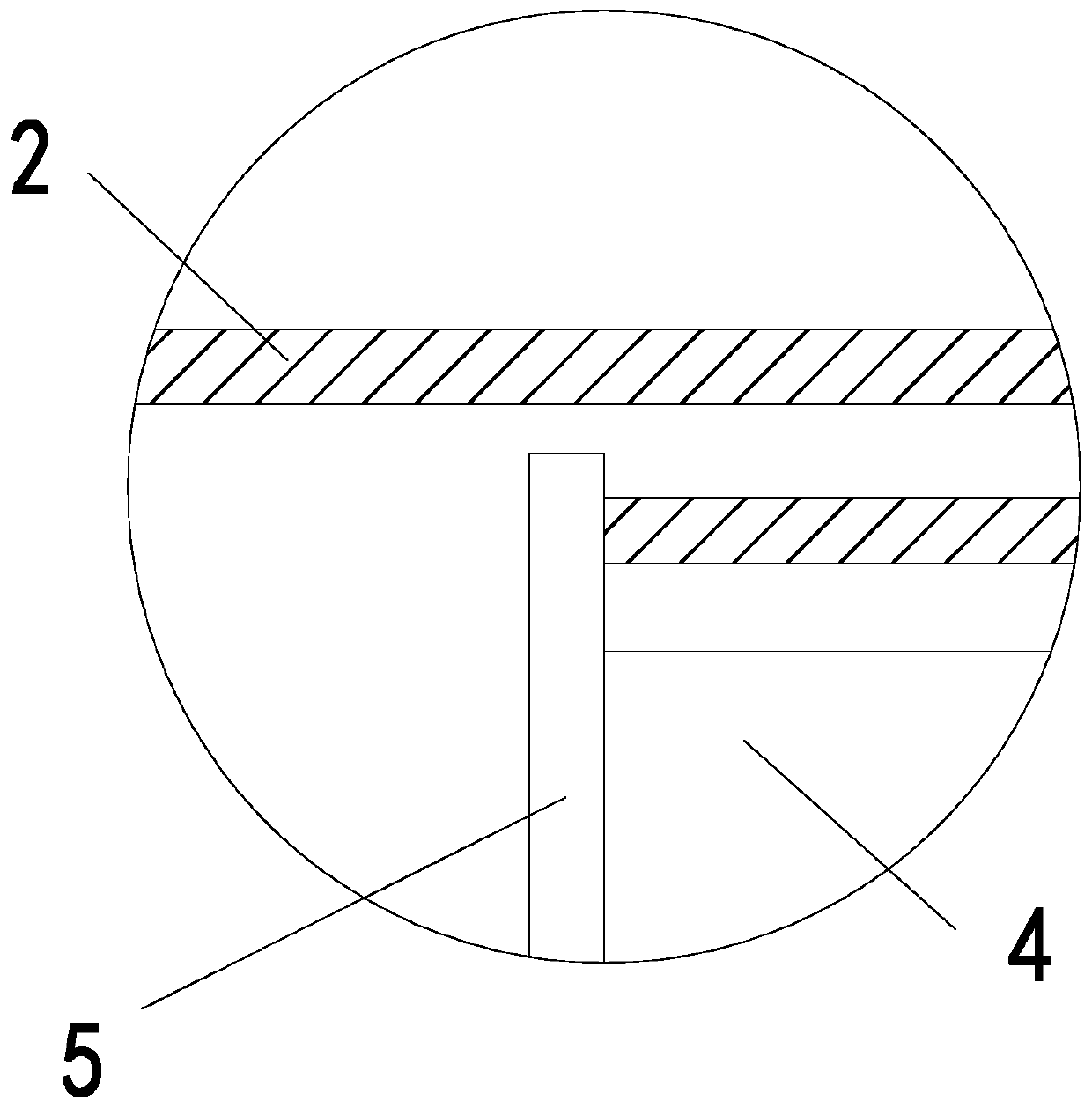

[0027] A double-tube constrained self-resetting anti-buckling support device based on Belleville springs, reference Figures 1 to 6 , including inner restraint steel pipe 1, outer restraint steel pipe 2, core energy-dissipating steel pipe 3, two conduits 6, two positioning plates 4, two positioning end plates 5, two outer end plates 8, two inner end plates 7, Two connection end plates 10, two sets of butterfly springs 11;

[0028] Specifically, one end of the positioning plate 4 is respectively inserted into two ports of the internal restraint steel pipe 1, one of the positioning plates 4 is welded to the inner wall of the inner restraint steel pipe 1, and the other positioning plate is spaced from the inner wall of the inner restraint steel pipe 1. A certain distance; the positioning plate 4 and the internal restraint steel pipe 1 are all ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com