Oil pumping unit semi-direct drive device

A driving device, semi-direct drive technology, applied in the direction of transmission, machine/engine, mechanical equipment, etc., can solve the problems of high maintenance cost, heavy maintenance workload, shutdown and replacement, etc., to achieve easy maintenance and avoid damage to the pumping unit , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present invention will be further described below in conjunction with accompanying drawing:

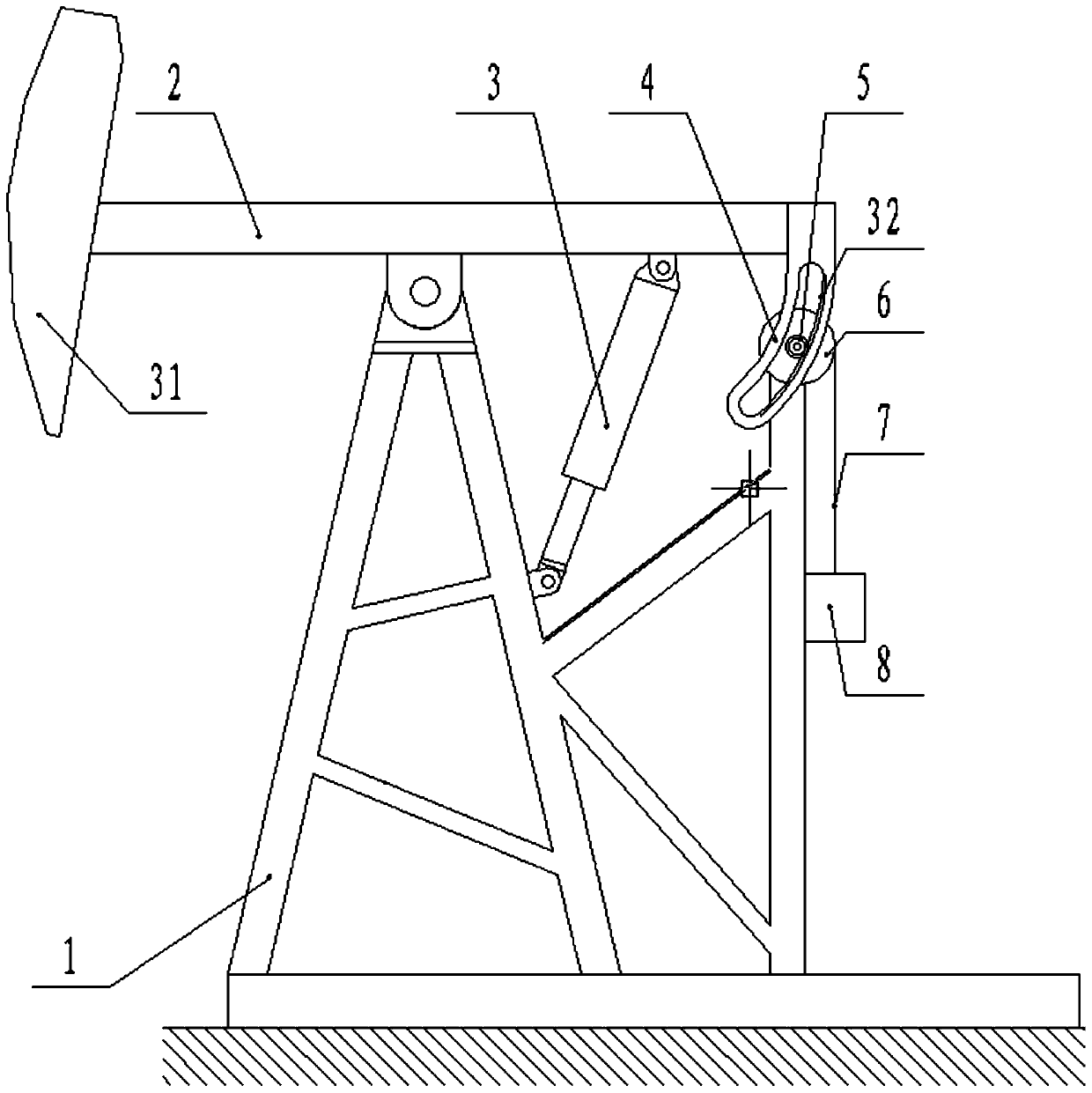

[0038] Such as figure 1 As shown, the present invention includes a support 1, a beam 2 and a driving mechanism 3, the middle part of the beam 2 is hinged on the top of the bracket 1, and the driving mechanism 3 is connected between the bracket 1 and the beam 2, and the above is a beam type oil pumping The basic structure of the machine will not be repeated here.

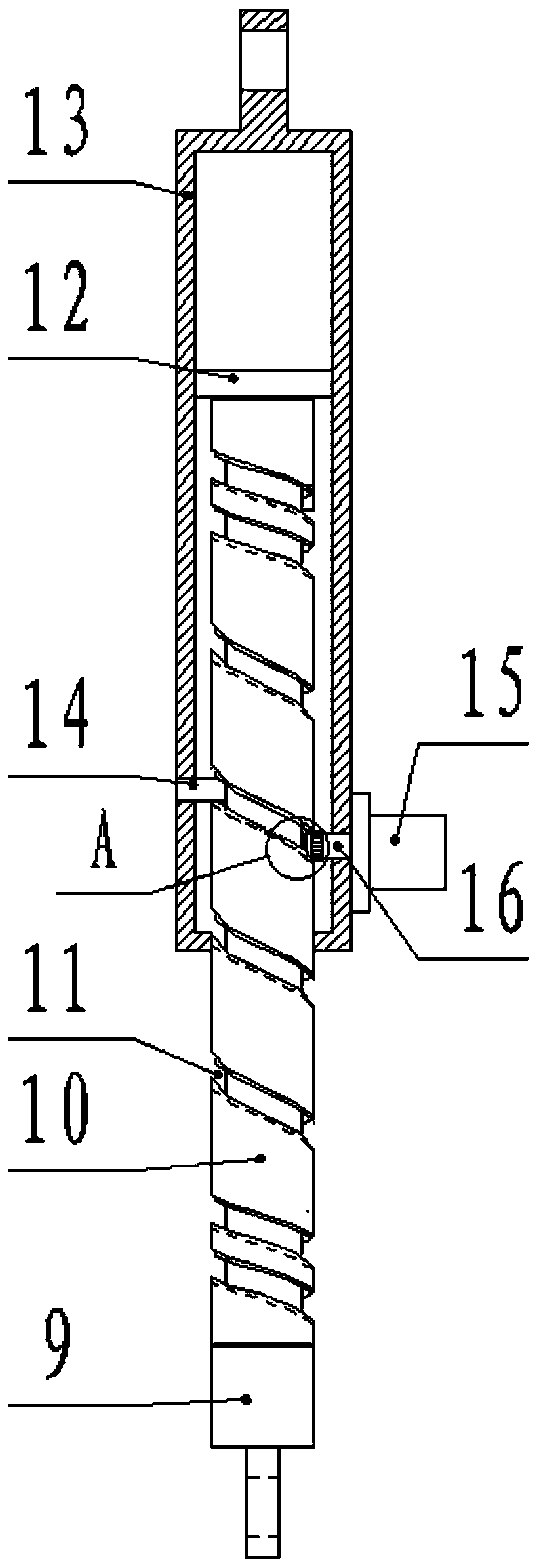

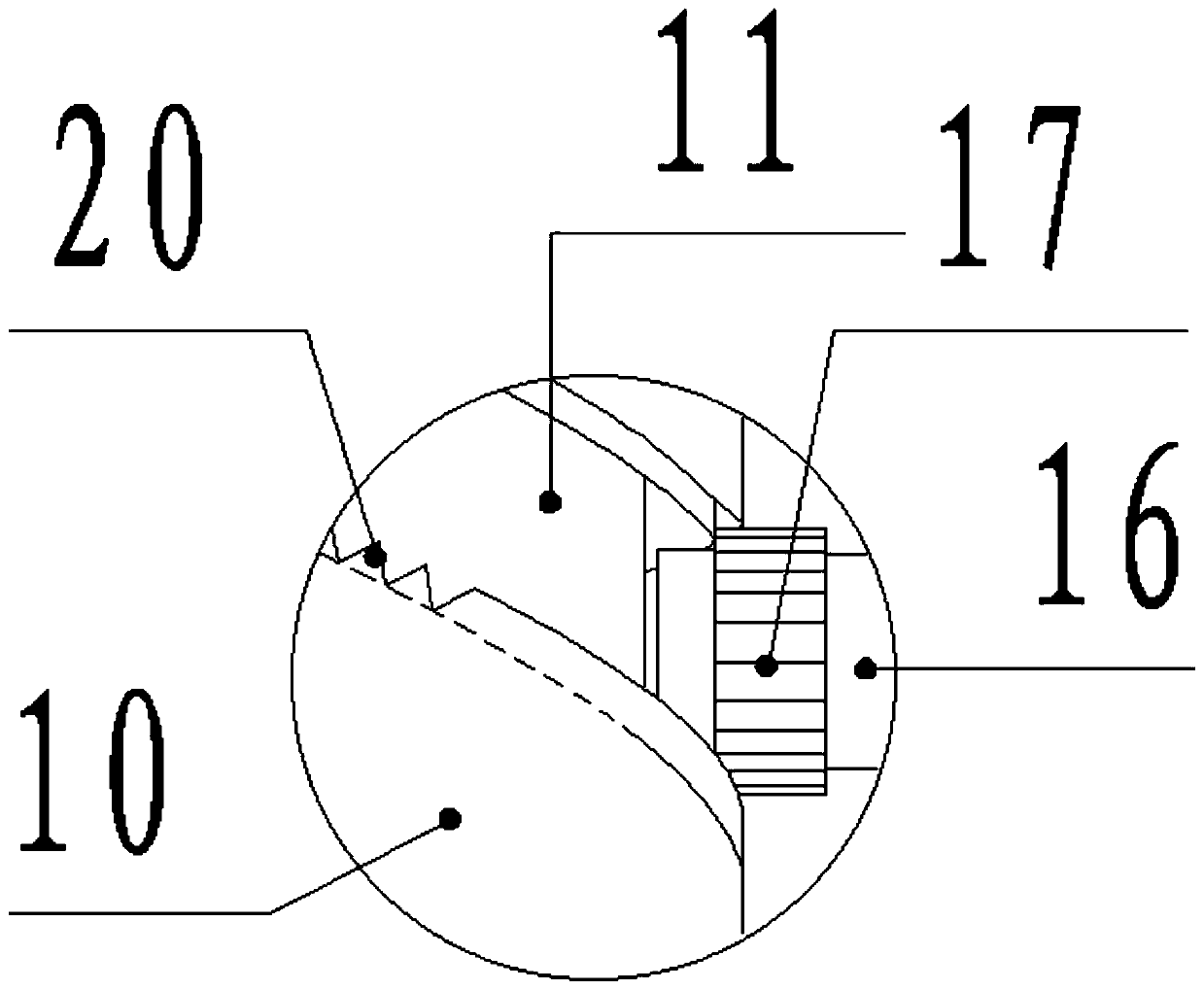

[0039] Such as figure 2 As shown, the driving mechanism 3 includes a cylinder A13, a screw shaft assembly and a motor 15. One end of the screw shaft assembly is inserted into the cylinder A13, the upper end of the cylinder A13 is hinged on the beam 2, and the lower end of the screw shaft assembly is hinged on bracket 1. During oil pumping, the drive mechanism 3 expands and contracts under the drive of the motor 15, so that the beam 2 swings to realize the oil pumping action.

[0040] Such as Figure 6As show...

Embodiment 2

[0062] The difference between this embodiment and the first embodiment lies in the structure of the counterweight mechanism.

[0063] In this embodiment, the counterweight mechanism includes an arc guide rail 4, a follower gear 5, a wheel disc 6 and a counterweight 8. The arc guide rail 4 is fixedly connected to the bracket 1, and the center of the circle where the arc guide rail 4 is located is located on the beam. 2, an arc-shaped rack 32 is processed on the inner side of the arc-shaped guide rail 4, and the follower gear 5 is installed on the tail of the beam 2 through the gear shaft, and the follow-up gear 5 meshes with the arc-shaped rack 32 , the wheel disc 6 and the follower gear 5 are installed on the same shaft, so as to rotate synchronously with the follower gear 5 , the outer edge of the wheel disc 6 is provided with a rope groove, and a soft rope 7 is wound in the rope groove, and the soft rope 7 Hanging down from the edge of the wheel disc 6 along the tangential d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com