A method for long-distance pipeline transportation of mortar to treat abandoned open-pit basins in mines

A pipeline transportation, long-distance technology, applied in ground mining, earth drilling, underground mining, etc., can solve the impact of underground mining and other issues, to achieve the effect of ensuring safe production, reducing pollution and damage, and protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

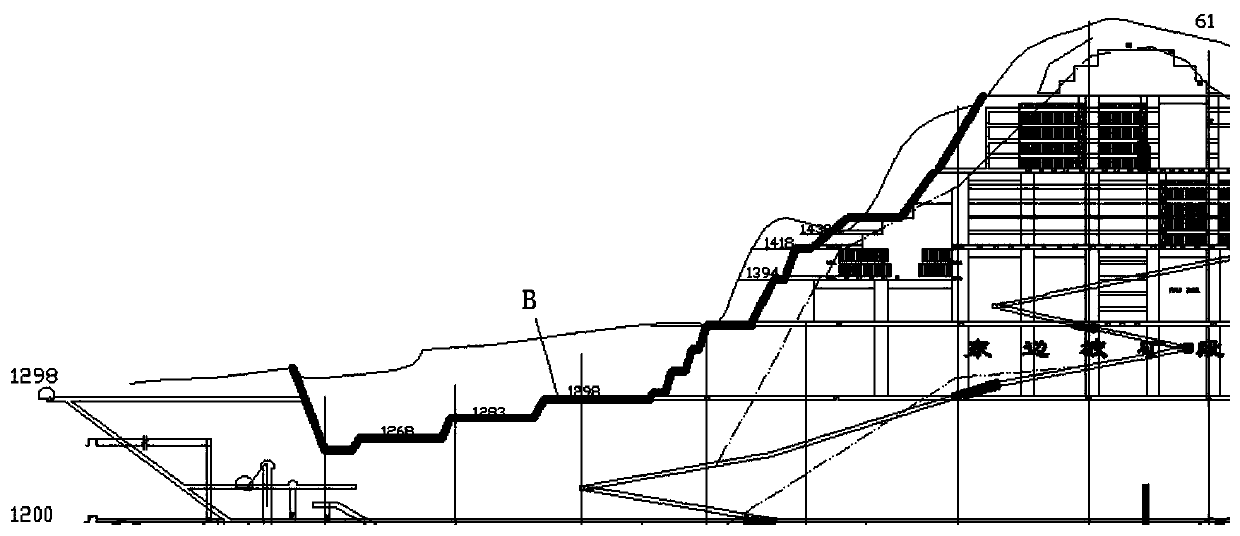

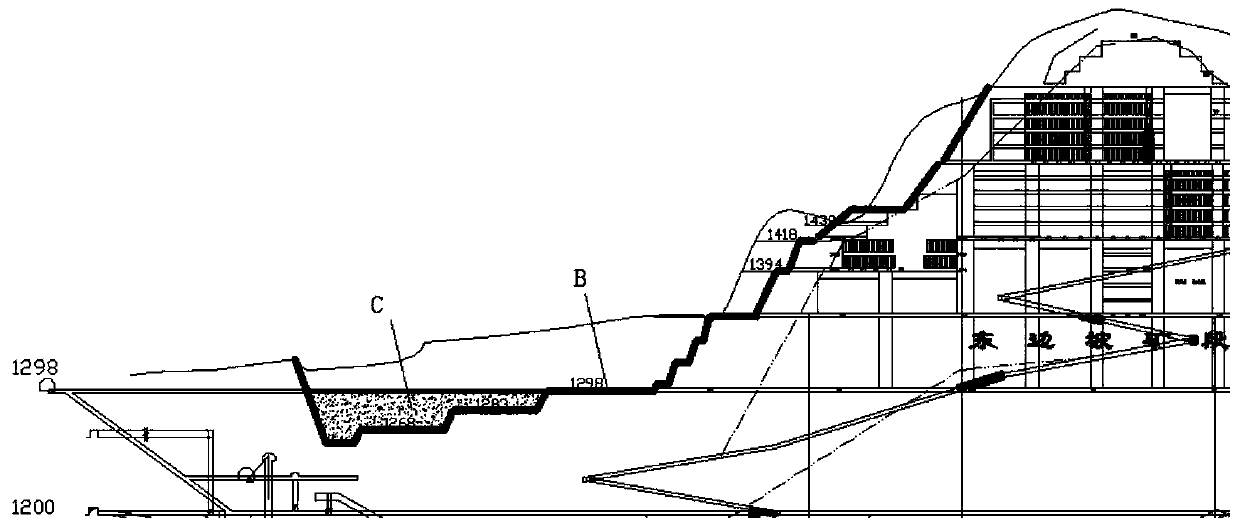

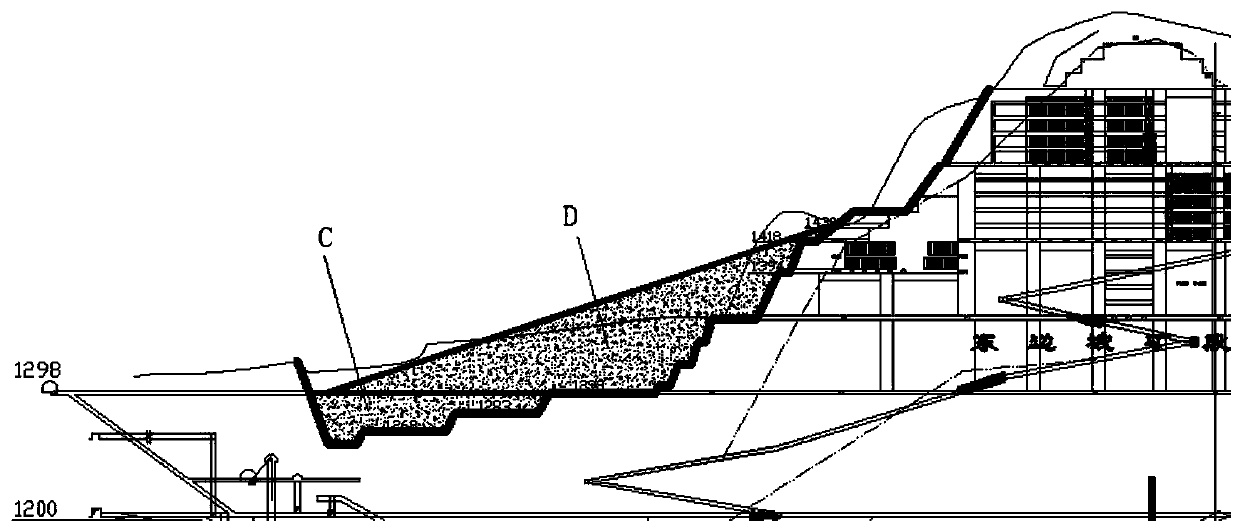

[0036] refer to Figure 1 to Figure 7 , for a further detailed description of the actual implementation process of governance. details as follows:

[0037] (1) According to the actual production situation of the mine, determine the reasonable number of staged treatment;

[0038] The governance of open-air basins is usually divided into two phases, bounded by a closed circle. Below the closed circle is the first-phase treatment project, and above the closed circle is the second-phase treatment project. The first-phase treatment project is carried out simultaneously with the underground mining production, and the underground mining method must be the non-pillar segmental caving mining method to form a certain thickness of waste rock cushion. The thickness of the waste rock cushion is usually 50-100m.

[0039] The filling body filled in the open-pit basin in the first phase of the treatment project will drop together with the waste rock cushion along with the decline of minin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com