Pipe jacking construction method for municipal sewage pipes

A technology for sewage pipes and construction methods, applied in tunnels, drill pipes, casings, etc., can solve the problems of pipe jacking deviation, reduce construction efficiency, and easy damage, and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

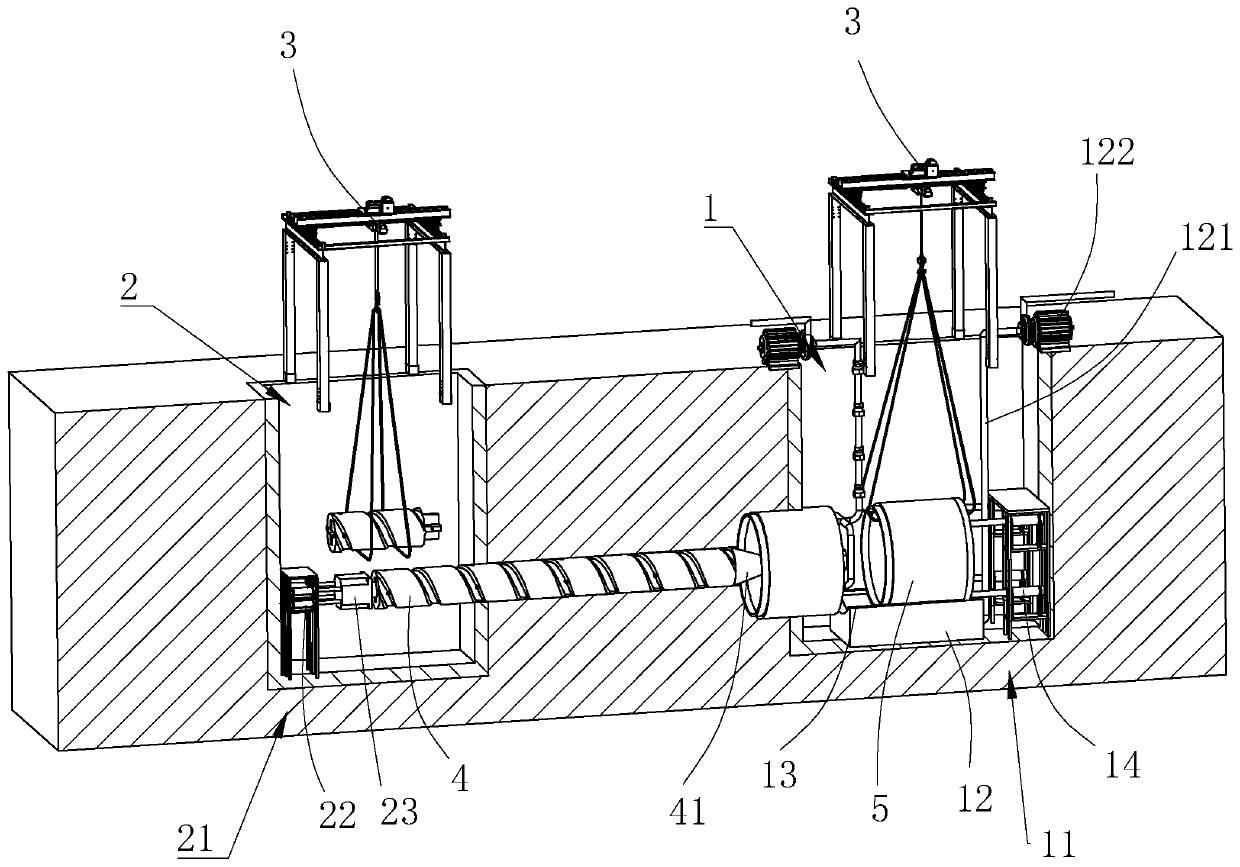

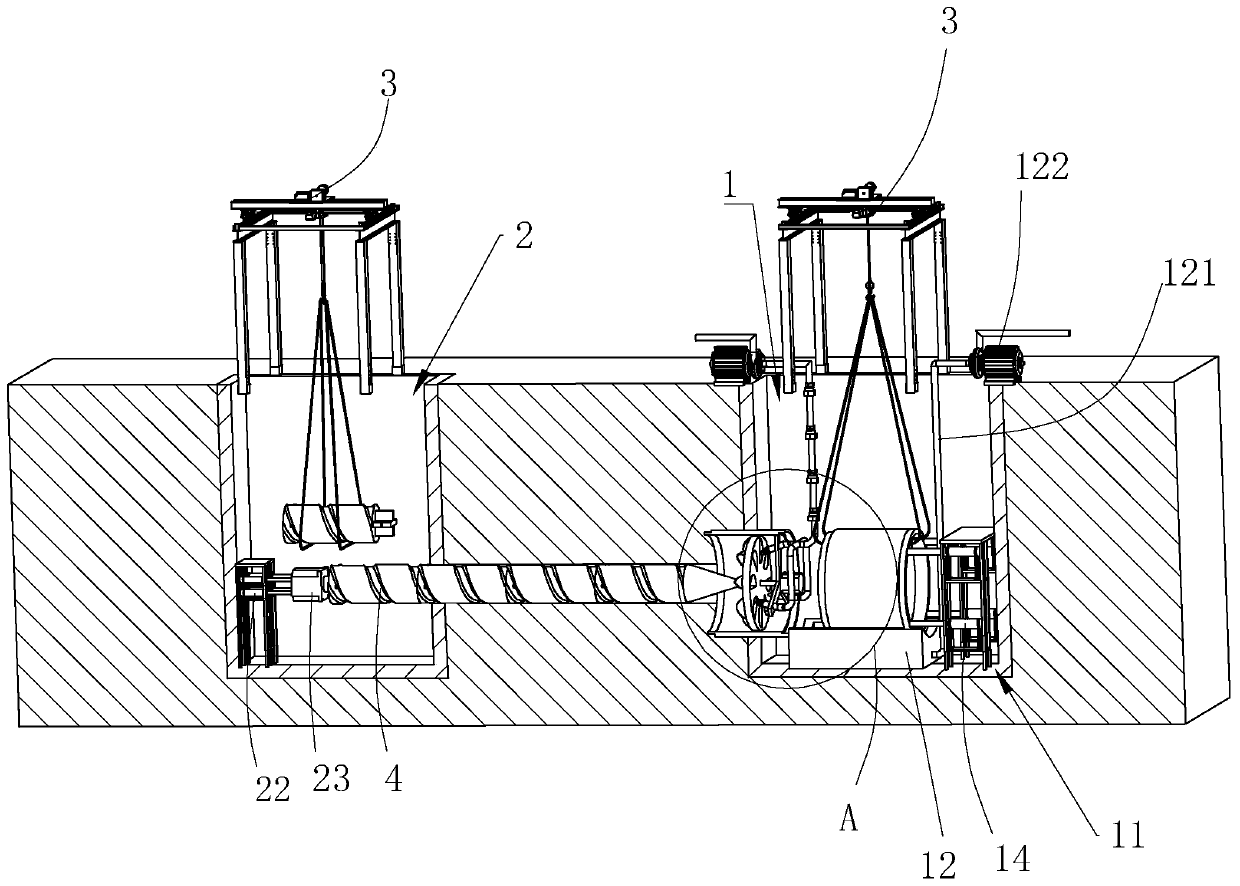

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

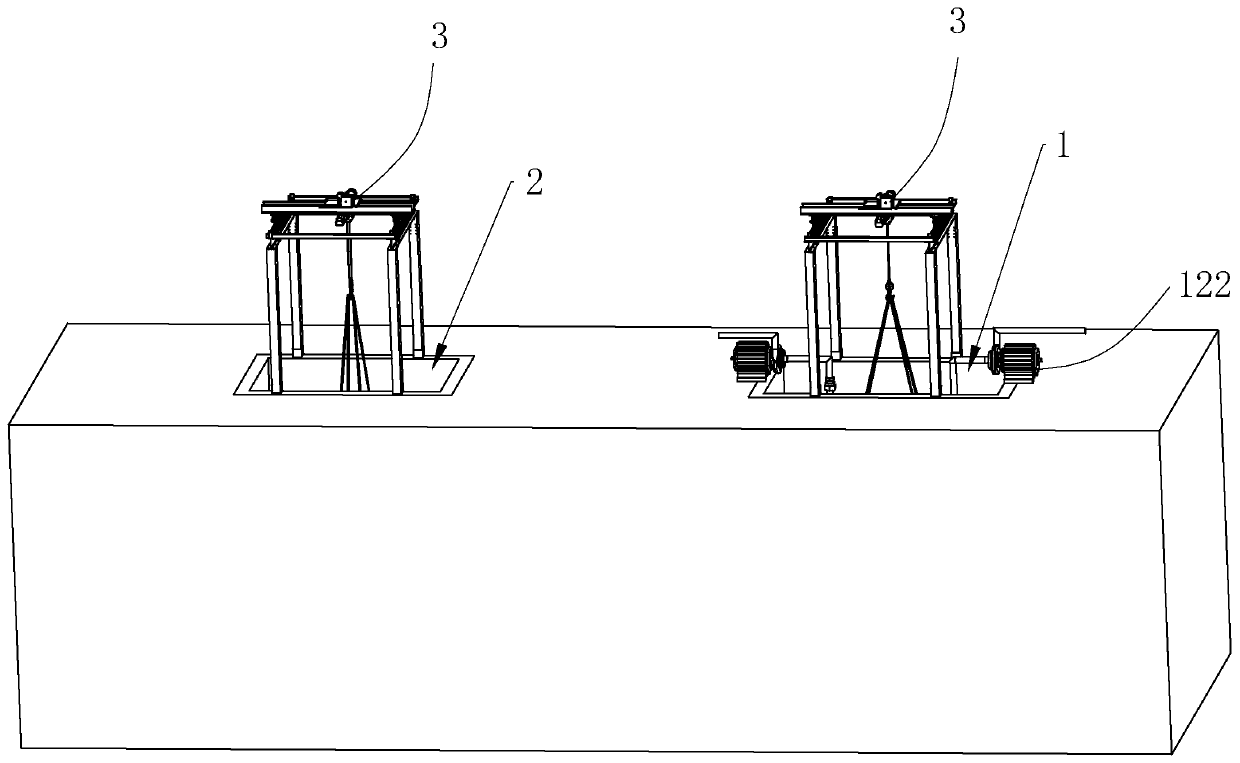

[0047] Such as Figure 1 to Figure 2 As shown, a kind of municipal sewage pipeline pipe jacking construction method disclosed by the present invention comprises the following steps:

[0048] a. Excavation of working well 1 and receiving well 2: According to the center line of the design pipeline and the positions of both ends, excavate working well 1 and receiving well 2 at the selected construction position; the net depth of working well 1 and receiving well 2 is From three meters to nine meters, the side walls around the working well 1 and the receiving well 2 are poured with reinforced concrete. , The bearing capacity of the bottom of receiving well 2.

[0049] b. Crane 3 installation: set up a movable crane 3 above the working well 1 and receiving well 2; set up a movable working platform on the working well 1 and receiving well 2, set a lifting frame o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com